Reflection and heat-insulation coating and preparation method thereof

A reflective thermal insulation coating and formulation technology, applied in the field of coatings, can solve problems such as poor thermal insulation effect, and achieve excellent construction performance, good shielding effect, and the effect of strengthening thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

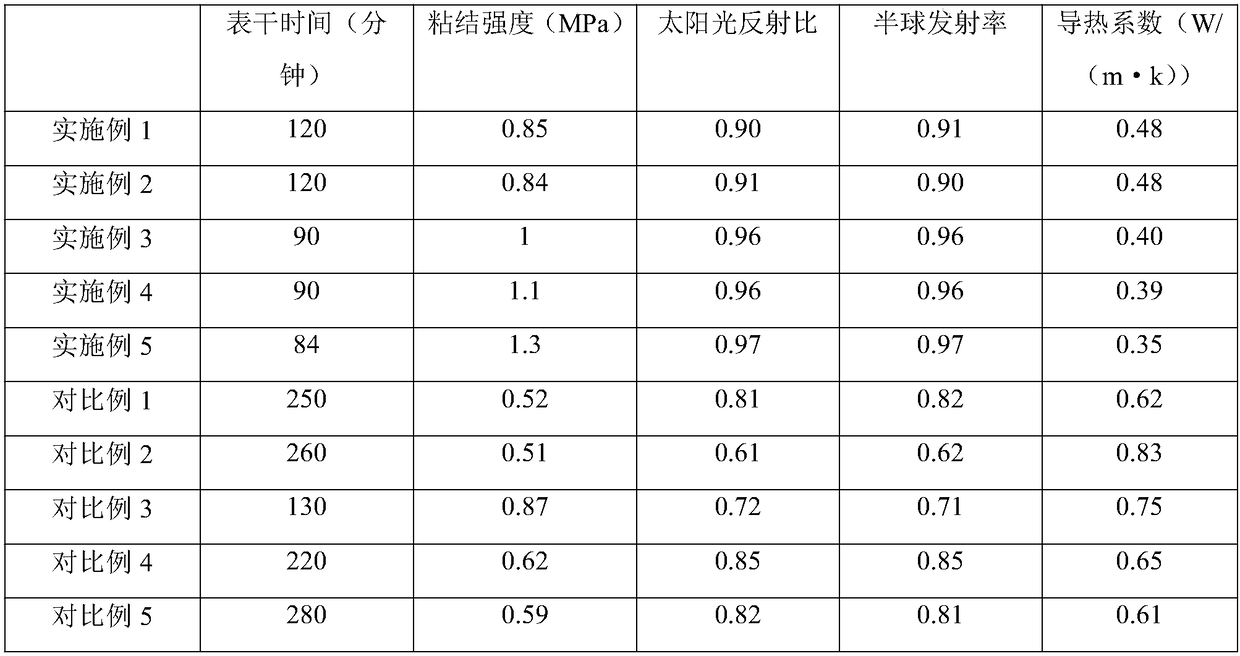

Examples

Embodiment 1

[0033] A reflective heat-insulating coating, which is made of the following components by weight: 30 parts of water-based acrylic emulsion, 15 parts of pure acrylic emulsion, 10 parts of silicone acrylic resin, and 5 parts of sucrose polyester modified polymethyl methacrylate , 3 parts of lithium silicate, 2 parts of nano-tungsten trioxide, 2 parts of nano-aluminum silicate, 2 parts of nano-titanium dioxide, 5 parts of dispersant, 0.3 parts of leveling agent, 1 part of film-forming aid, 1 part of silane coupling agent , 20 parts of deionized water.

[0034] Among them, pure acrylic emulsion is a copolymer made of butyl acrylate and methyl methacrylate. The dispersant is a polycarboxylate ammonium dispersant. The leveling agent is polydimethylsiloxane. The film-forming aid is ethylene glycol butyl ether. The silane coupling agent is a modified aminosilane coupling agent.

[0035] The preparation method of above-mentioned a kind of reflective heat-insulating paint, concrete ...

Embodiment 2

[0046] A reflective heat-insulating coating, which is made of the following components by weight: 40 parts of water-based acrylic emulsion, 20 parts of pure acrylic emulsion, 12 parts of silicone acrylic resin, 6 parts of sucrose polyester modified polymethyl methacrylate , 4 parts of lithium silicate, 3 parts of nano-tungsten trioxide, 3 parts of nano-aluminum silicate, 3 parts of nano-titanium dioxide, 8 parts of dispersant, 0.5 parts of leveling agent, 2 parts of film-forming aid, 2 parts of silane coupling agent , 25 parts of deionized water.

[0047] Among them, pure acrylic emulsion is a copolymer made of butyl acrylate and methyl methacrylate. The dispersant is a polycarboxylate ammonium dispersant. The leveling agent is polydimethylsiloxane. The film-forming aid is ethylene glycol butyl ether. The silane coupling agent is an epoxy-based organosilane coupling agent.

[0048] The preparation method of above-mentioned a kind of reflective heat-insulating paint, concre...

Embodiment 3

[0059] A reflective heat-insulating coating, which is made of the following components by weight: 30 parts of water-based acrylic emulsion, 20 parts of pure acrylic emulsion, 10 parts of silicone acrylic resin, and 6 parts of sucrose polyester modified polymethyl methacrylate , 3 parts of lithium silicate, 3 parts of nano-tungsten trioxide, 2 parts of nano-aluminum silicate, 3 parts of nano-titanium dioxide, 5 parts of dispersant, 0.5 parts of leveling agent, 1 part of film-forming aid, 2 parts of silane coupling agent , 20 parts of deionized water.

[0060] Among them, pure acrylic emulsion is a copolymer made of butyl acrylate and methyl methacrylate. The dispersant is a polycarboxylate ammonium dispersant. The leveling agent is polydimethylsiloxane. The film-forming aid is ethylene glycol butyl ether. The silane coupling agent is a modified aminosilane coupling agent.

[0061] The preparation method of above-mentioned a kind of reflective heat-insulating paint, concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com