Fabric care compositions

A composition and fabric treatment technology, applied in the direction of detergent composition, organic cleaning composition, inorganic/elemental cleaning composition, etc., can solve the problems of not satisfying consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

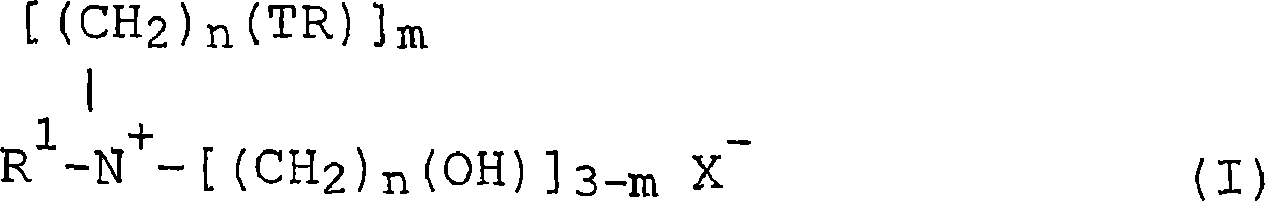

Method used

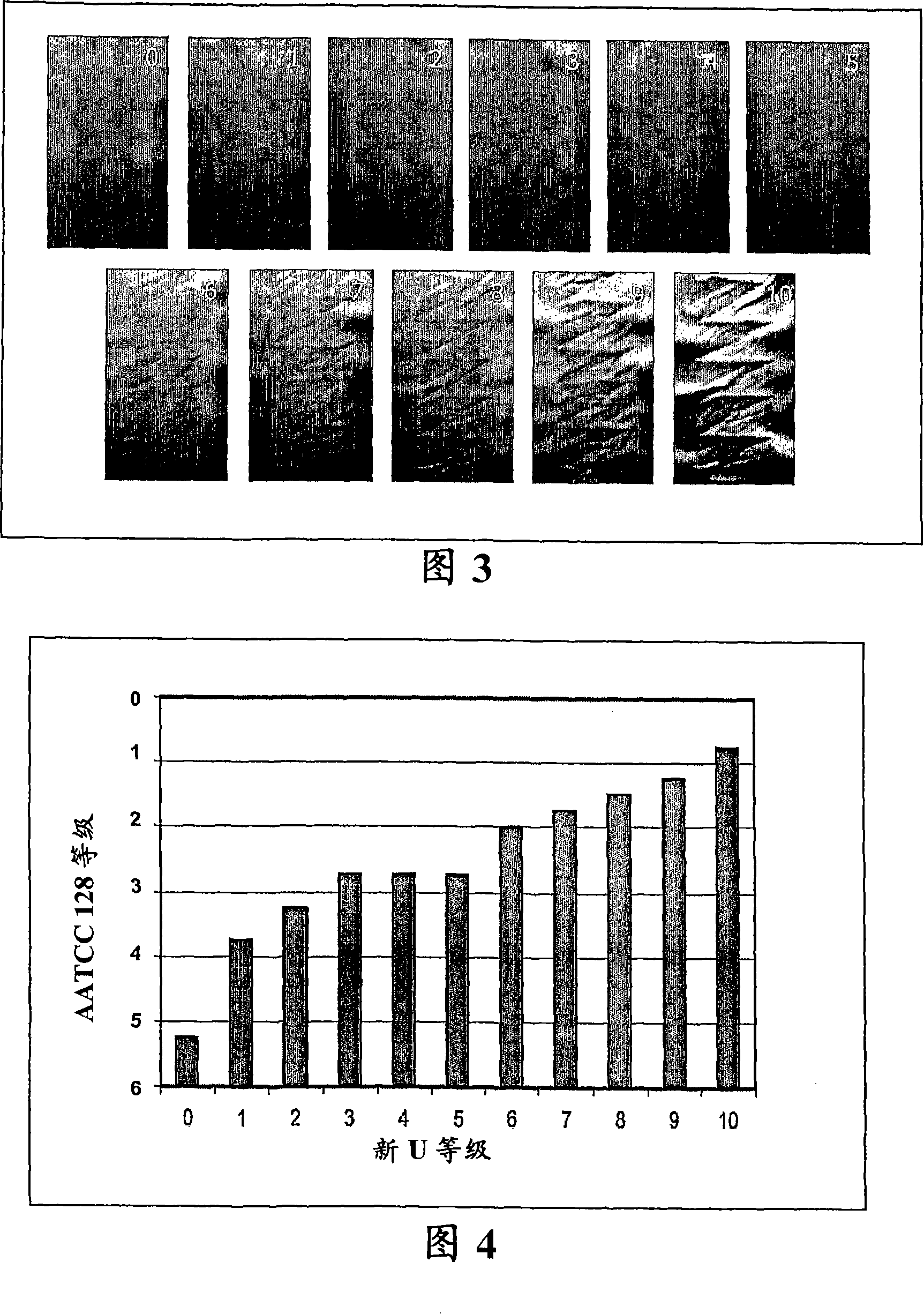

Image

Examples

Embodiment Construction

[0043] The composition of the present invention is typically used as part of a fabric care composition delivered to the rinse cycle of an automatic washing machine.

[0044] Nanoparticles

[0045] The composition of the present invention comprises a dispersion of nanoparticles that acts as a friction component when deposited on a fabric. The particles can be inorganic or organic nanoparticles or a mixture of one or more nanoparticles.

[0046] Suitable inorganic nanoparticles include silicon dioxide (SiO 2 ), titanium dioxide (TiO 2 ), alumina (Al 2 O 3 ), zinc oxide (ZnO) and mixed oxides such as ITO (indium tin oxide, In 2 O 3 -SnO 2 ).

[0047] The readily available and preferred inorganic nanoparticles are amorphous silica obtained in the form of sol or colloid, as defined in The Chemistry of Silica, RK Iler, Wiley-Interscience, New York, 1979, page 330.

[0048] The silica nanoparticles can also be a non-silicon core, as long as the surface of the nanoparticles is coated with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com