Method for processing pizza cheese

A processing method and cheese technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of long processing and production cycle and high production cost, and achieve the effect of reducing processing cost, reducing production cost and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

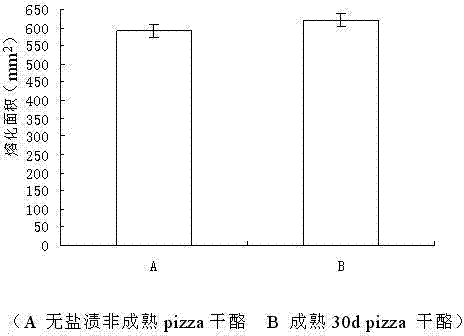

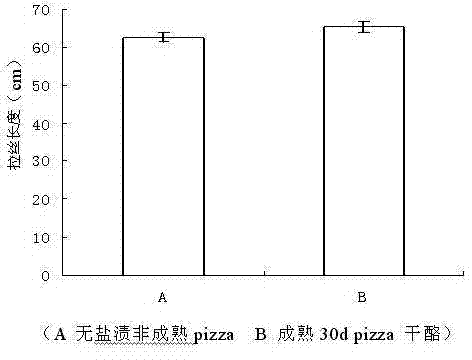

Image

Examples

Embodiment 1

[0044] (1) Filtration of raw milk:

[0045] Fresh milk, the raw material, is filtered once through a 200-mesh filter cloth, and placed in a cheese processing tank;

[0046] (2) Standardization:

[0047] Standardization is carried out by adding low-temperature skim milk powder. Heat the raw materials in step (1) to 40°C, add an appropriate amount of low-temperature skim milk powder, and adjust the ratio of protein to fat in the raw milk to be protein:fat=1.42. Then the temperature was kept stirring for 5 minutes;

[0048] (3) Pasteurization:

[0049] Heat the raw milk in step (2) to 63.5°C in a cheese tank in a water bath, stir continuously during heating, and then keep it still for 30 minutes;

[0050] (4) cooling:

[0051] Rapidly cool the raw milk in step (3) to 15°C;

[0052] (5) Pre-acidification:

[0053] Add 20% (w / w) lactic acid solution to the raw milk in step (4), and keep stirring to adjust the titrated acidity of the raw milk to 21 o T, then continue to sti...

Embodiment 2

[0080] (1) Filtration of raw milk:

[0081] Fresh milk, the raw material, is filtered once through a 200-mesh filter cloth, and placed in a cheese processing tank;

[0082] (2) Standardization:

[0083] Standardize by adding low-temperature skim milk powder. Heat the raw materials in step (1) to 50°C, add an appropriate amount of low-temperature skim milk powder, and adjust the ratio of protein to fat in the raw milk to be protein:fat=1.42. Then the temperature was kept stirring for 10 minutes;

[0084] (3) Pasteurization:

[0085] Heat the raw milk in step (2) to 63.5°C in a cheese tank in a water bath, stir continuously during heating, and then keep it still for 30 minutes;

[0086] (4) cooling:

[0087] Rapidly cool the raw milk in step (3) to 20°C;

[0088] (5) Pre-acidification:

[0089] Add 20% (w / w) lactic acid solution to the raw milk in step (4), and keep stirring to adjust the titrated acidity of the raw milk to 24 o T, then continue to stir for 10min;

[0...

Embodiment 3

[0116] (1) Filtration of raw milk:

[0117] Fresh milk, the raw material, is filtered once through a 200-mesh filter cloth, and placed in a cheese processing tank;

[0118] (2) Standardization:

[0119] Standardization is carried out by adding low-temperature skim milk powder. Heat the raw materials in step (1) to 40°C, add an appropriate amount of low-temperature skim milk powder, and adjust the ratio of protein to fat in the raw milk to be protein:fat=1.42. Then the temperature was kept stirring for 8 minutes;

[0120] (3) Pasteurization:

[0121] Heat the raw milk in step (2) to 63.5°C in a cheese tank in a water bath, stir continuously during heating, and then keep it still for 30 minutes;

[0122] (4) cooling:

[0123] Rapidly cool the raw milk in step (3) to 16°C;

[0124] (5) Pre-acidification:

[0125] Add 20% (w / w) lactic acid solution to the raw milk in step (4), and keep stirring to adjust the titrated acidity of the raw milk to 22 o T, then continue to sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com