Food-grade lubricant using sucrose polyester as base oil and preparation method thereof

A technology for sucrose polyester and lubricating oil, which is applied in lubricating compositions, petroleum industry, etc., can solve the problem of not controlling the hygienic quality indicators of lubricating oil products, making requirements for the quality standard of sucrose polyester, and not defining the degree of esterification of sucrose polyester, etc. problems to ensure quality, ensure hygiene and safety, and optimize lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

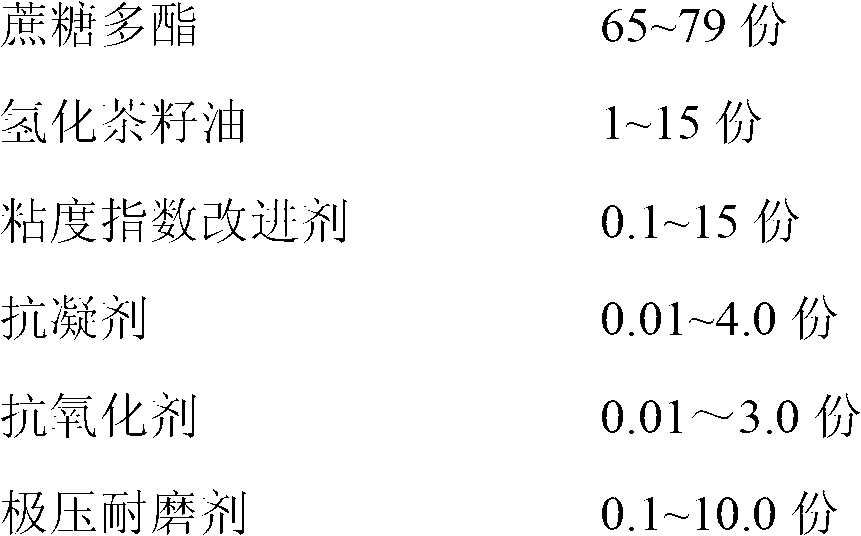

[0052] A food-grade lubricating oil based on sucrose polyester with an esterification degree of 6-8 and a preparation method thereof. The raw material composition formula is as follows:

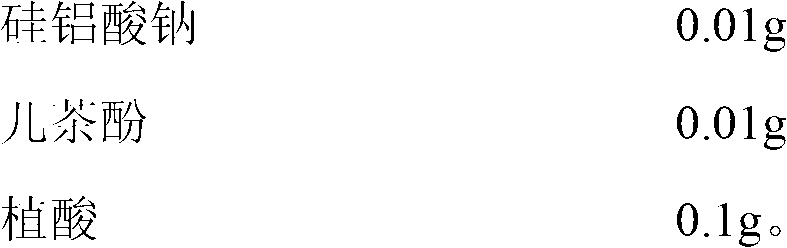

[0053]

[0054]

[0055] The average degree of esterification of the sucrose polyester used in this example is 7.5, the appearance is oily viscous liquid, tasteless or slightly greasy, and its physical and chemical indicators meet the national standard "Food Additives Sucrose Fatty Ester" (GB 8272-2005), That is, acid value ≤ 6.0mg / g, free sugar ≤ 10.0%, moisture ≤ 4.0%, ash content ≤ 4.0%, arsenic ≤ 1.0mg / kg, lead ≤ 2.0mg / kg.

[0056] The method for preparing the food-grade lubricating oil with sucrose polyester as base oil according to the formula requirements comprises the following steps:

[0057] (1) Pre-mixing: Weigh each raw material according to the proportion by weight, add sucrose polyester, hydrogenated tea seed oil, sodium aluminosilicate, polyisobutylene, catechol and phyti...

Embodiment 2

[0062] A food-grade lubricating oil based on sucrose polyester with an esterification degree of 6-8 and a preparation method thereof. The raw material composition formula is as follows:

[0063]

[0064] The average degree of esterification of the sucrose polyester used in this example is 7.0, the appearance is an oily viscous liquid, tasteless or slightly greasy, and its physical and chemical indicators meet the national standard "Food Additives Sucrose Fatty Ester" (GB 10617-2005), That is, acid value ≤ 6.0mg / g, free sugar ≤ 10.0%, moisture ≤ 4.0%, ash content ≤ 4.0%, arsenic ≤ 1.0mg / kg, lead ≤ 2.0mg / kg.

[0065] The method for preparing the food-grade lubricating oil with sucrose polyester as base oil according to the formula requirements comprises the following steps:

[0066] (1) Pre-mixing: Weigh each raw material according to the proportion by weight, add sucrose polyester, hydrogenated tea seed oil, polyglycerin fatty acid ester, poly-n-butyl methacrylate, catechol ...

Embodiment 3

[0071] A food-grade lubricating oil based on sucrose polyester with an esterification degree of 6-8 and a preparation method thereof. The raw material composition formula is as follows:

[0072]

[0073] The average degree of esterification of the sucrose polyester used in this example is 6.2, the appearance is oily viscous liquid, tasteless or slightly greasy, and its physical and chemical indicators meet the national standard "Food Additives Sucrose Fatty Ester" (GB 8272-2005), That is, acid value ≤ 6.0mg / g, free sugar ≤ 10.0%, moisture ≤ 4.0%, ash content ≤ 4.0%, arsenic ≤ 1.0mg / kg, lead ≤ 2.0mg / kg.

[0074] The method for preparing the food-grade lubricating oil with sucrose polyester as base oil according to the formula requirements comprises the following steps:

[0075] (1) Pre-mixing: Weigh each raw material according to the proportion by weight, and mix sucrose polyester, hydrogenated tea seed oil, hydroxystearin, polystyrene-butadiene copolymer, tert-butyl hydroqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com