Coating with low-VOC sucrose polyester-modified alkyd emulsion as main material

A technology of sucrose polyester and alkyd emulsion, which is applied in the field of coatings and can solve problems such as impact on the environment and human health, and harm to the environment and human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Mix 24% sucrose polyester, 30% alkyd resin and 6% TX-10, put it into the magnetic rotor, heat and stir at 2.5r / min for 5min; put in 40% deionized water and heat to 75°C; take out Finally, emulsify under the high-speed shearing machine at a speed of 10000r / min, and add deionized water until the phase inversion; after the phase inversion, add the remaining water and reduce the speed to 5000r / min, continue emulsification for 5 minutes, and then finish it for later use.

Embodiment 2

[0022] Mix 30% sucrose polyester, 20% alkyd resin, 1.5% SDBS, 3.5% OP-10, put it into the magnetic rotor, heat and stir at 2.5r / min for 5min; add 45% deionized water at the same time and heat to 75°C; take it out and emulsify under a high-speed shearing machine at a speed of 10000r / min, and add deionized water at the same time until the phase inversion; after the phase inversion, add the remaining water and reduce the speed to 5000r / min, and continue emulsification for 5 minutes before ending. spare.

[0023] Coating embodiment one:

[0024] Stir at 500r / min, mix 0.4% dispersant and 9% water evenly, add 0.2% wetting agent and 0.1% rheological agent, add 9% titanium dioxide under stirring, then increase the speed to 1000r / min for high-speed dispersion 10 minutes; add 78% of the above emulsion to the pigment dispersion, stir at a high speed at a speed of 1000r / min, add 0.1% defoamer and 1.5% drier in sequence, and disperse for 5 minutes; add 0.4% pH regulator to adjust the pH t...

Embodiment example 2

[0026] Stir at 500r / min, mix 5% dispersant and 8.9% water evenly, add 0.1% wetting agent and 0.1% rheological agent, add 8.9% titanium dioxide under stirring, then increase the speed to 1000r / min for high-speed dispersion 10 minutes; add 73.7% of the above emulsion into the pigment dispersion, stir at a high speed at a speed of 1000r / min, add 0.1% defoamer and 2% drier in sequence, and disperse for 5 minutes; add 0.3% pH regulator to adjust the pH to 8.27, then add 1% thickener and mix evenly, continue to disperse for 20 minutes and then filter to obtain the low-VOC sucrose polyester modified alkyd emulsion as the main ingredient coating.

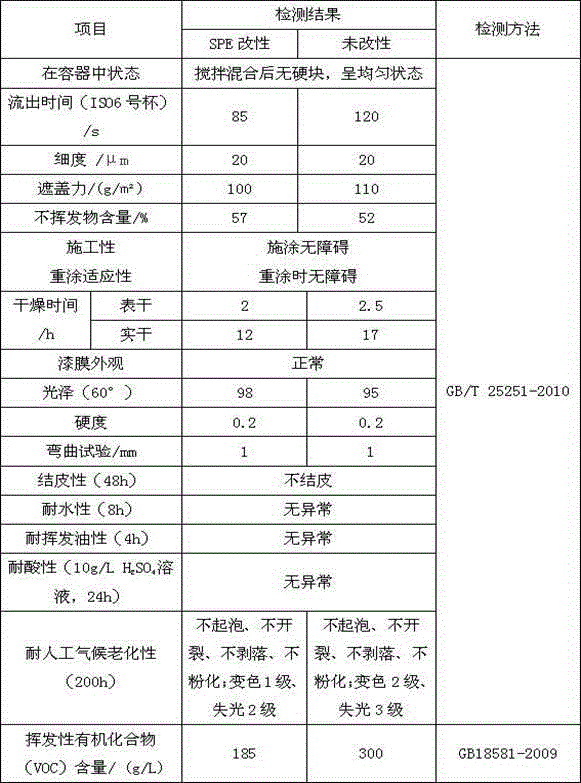

[0027] The sucrose polyester modified emulsion prepared by emulsion embodiment one of the present invention and coating embodiment one is compared with the coating prepared and the existing water-based alkyd resin coating, and the results are as follows 2 tables:

[0028] project SPE modified alkyd emulsion Unmodified waterborn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com