Porous lamellar-structured bismuth tungstate film as well as preparation method and application thereof

A network structure, bismuth tungstate technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of poor recycling performance, low recovery rate of small-sized particles, etc., and achieve improved film uniformity and high gloss. The effect of easy current and experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

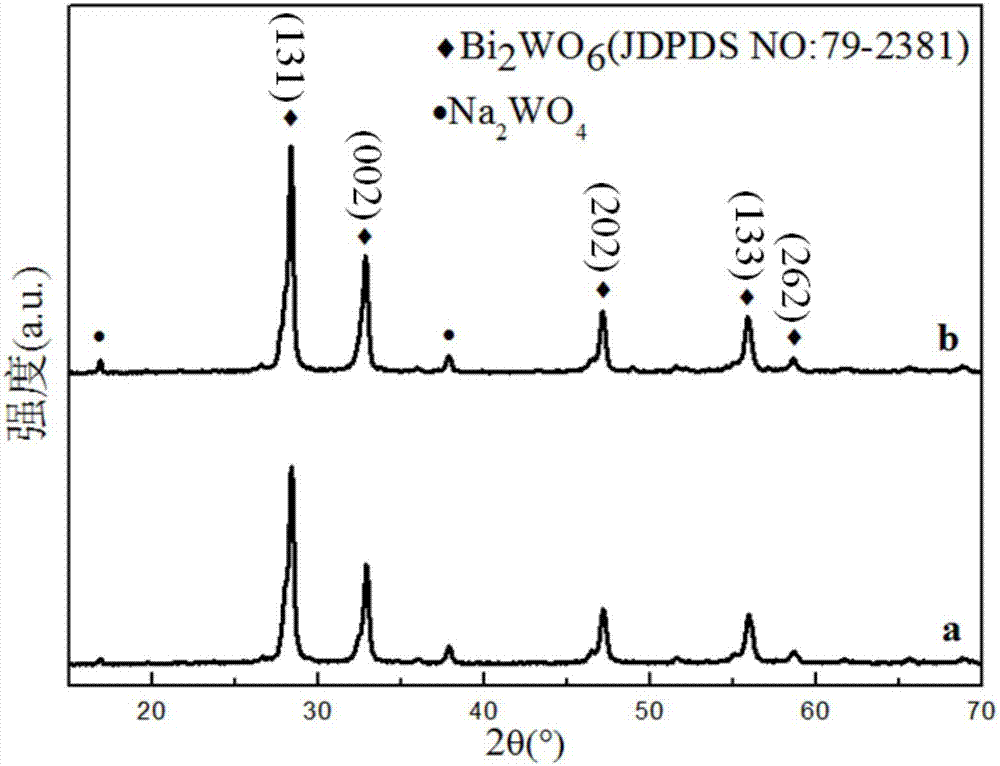

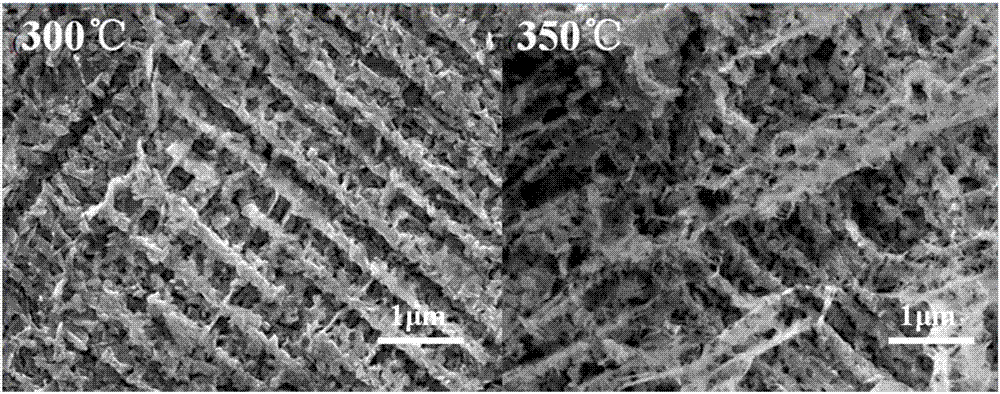

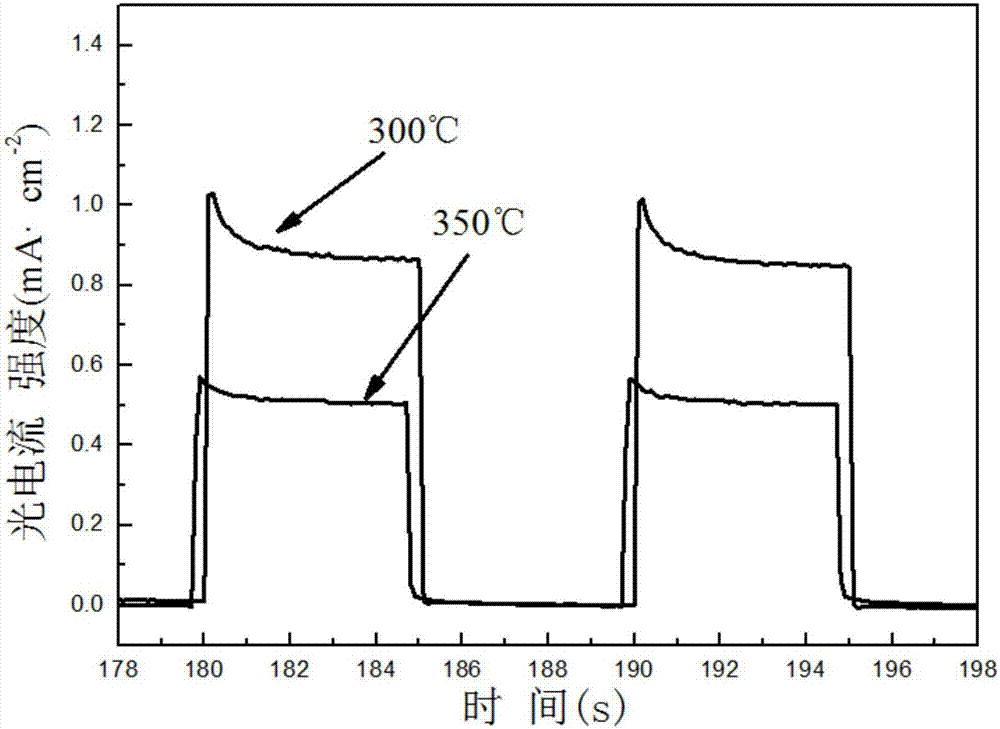

[0030]Step 1: the raw material Na 2 WO 4 Dissolved in ethylene glycol, prepared into a 0.30mol / L solution, recorded as solution A, Bi(NO 3 ) 3 Dissolved in ethylene glycol, prepared into a 0.60mol / L solution, recorded as solution B, according to the molar ratio of Bi to W of 2:1, slowly added solution A into solution B and vigorously stirred to form a colorless Clarified Bi 2 WO 6 solution, continue to stir for 1h to make it evenly mixed to obtain Bi 2 WO 6 Precursor solution; the Bi 2 WO 6 The precursor solution was left standing for 12h to obtain a colorless and clear Bi 2 WO 6 Sol (remains colorless and clear after aging);

[0031] Step 2: Place the cut FTO glass substrate in detergent, acetone, and ethanol in sequence for ultrasonic cleaning, rinse with a large amount of distilled water after each ultrasonic cleaning for 10 minutes, and finally blow dry with nitrogen, and then put the FTO glass substrate in After drying in an oven and standing to room temperatur...

Embodiment 2

[0035] Step 1: the raw material Na 2 WO 4 Dissolved in ethylene glycol, prepared into a 0.30mol / L solution, recorded as solution A, Bi(NO 3 ) 3 Dissolved in ethylene glycol, prepared into a 0.60mol / L solution, recorded as solution B, according to the molar ratio of Bi to W of 2:1, slowly added solution A into solution B and vigorously stirred to form a colorless Clarified Bi 2 WO 6 solution, continue to stir for 1.1h to make it evenly mixed, and obtain Bi 2 WO 6 Precursor solution; the Bi 2 WO 6 The precursor solution was left standing for 12h to obtain a colorless and clear Bi 2 WO 6 Sol (remains colorless and clear after aging);

[0036] Step 2: Place the cut FTO glass substrate in detergent, acetone, and ethanol in sequence for ultrasonic cleaning, rinse with a large amount of distilled water after each ultrasonic cleaning for 10 minutes, and finally blow dry with nitrogen, and then put the FTO glass substrate in After drying in an oven and standing to room tempe...

Embodiment 3

[0040] Step 1: the raw material Na 2 WO 4 Dissolved in ethylene glycol, prepared into a 0.28mol / L solution, recorded as solution A, Bi(NO 3 ) 3 Dissolved in ethylene glycol, prepared into a 0.56mol / L solution, recorded as solution B, according to the molar ratio of Bi to W of 2:1, slowly added solution A into solution B and vigorously stirred to form a colorless Clarified Bi 2 WO 6 solution, continue to stir for 1.2h to make it evenly mixed to obtain Bi 2 WO 6 Precursor solution; the Bi 2 WO 6 The precursor solution was left standing for 11.5h to obtain a colorless and clear Bi 2 WO 6 Sol (remains colorless and clear after aging);

[0041] Step 2: Place the cut FTO glass substrate in detergent, acetone, and ethanol in sequence for ultrasonic cleaning, rinse with a large amount of distilled water after each ultrasonic cleaning for 10 minutes, and finally blow dry with nitrogen, and then put the FTO glass substrate in After drying in an oven and standing to room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com