Method for preparing candied haw-shaped pure anatase type nano-titania wire in larger scale

A nano-titanium dioxide, anatase-type technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of not obtaining pure anatase-type titanium dioxide nanostructures and candied haws-shaped nanowires, etc. Achieve the effect of low production cost, good dispersion and parameter control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

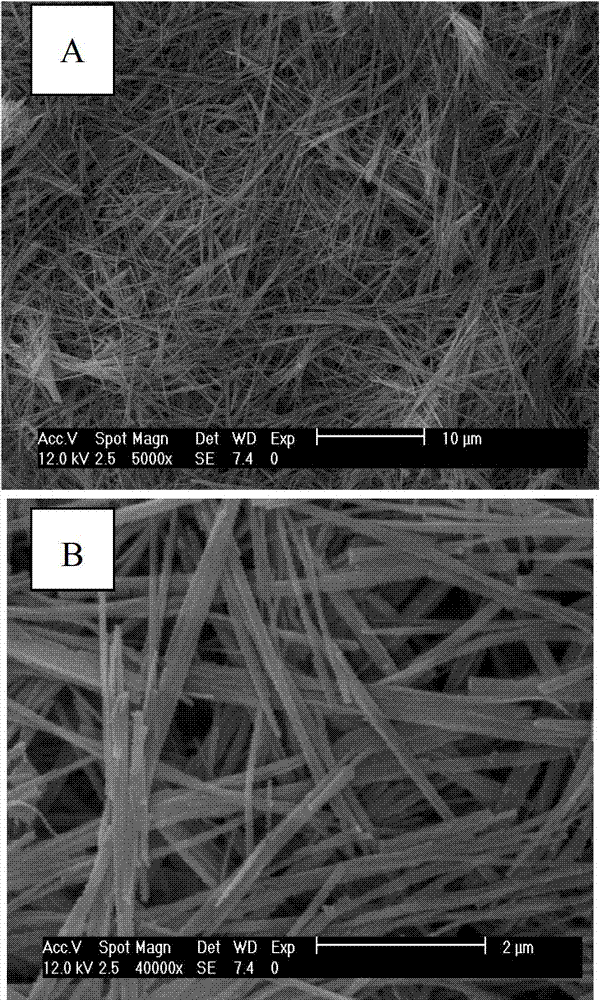

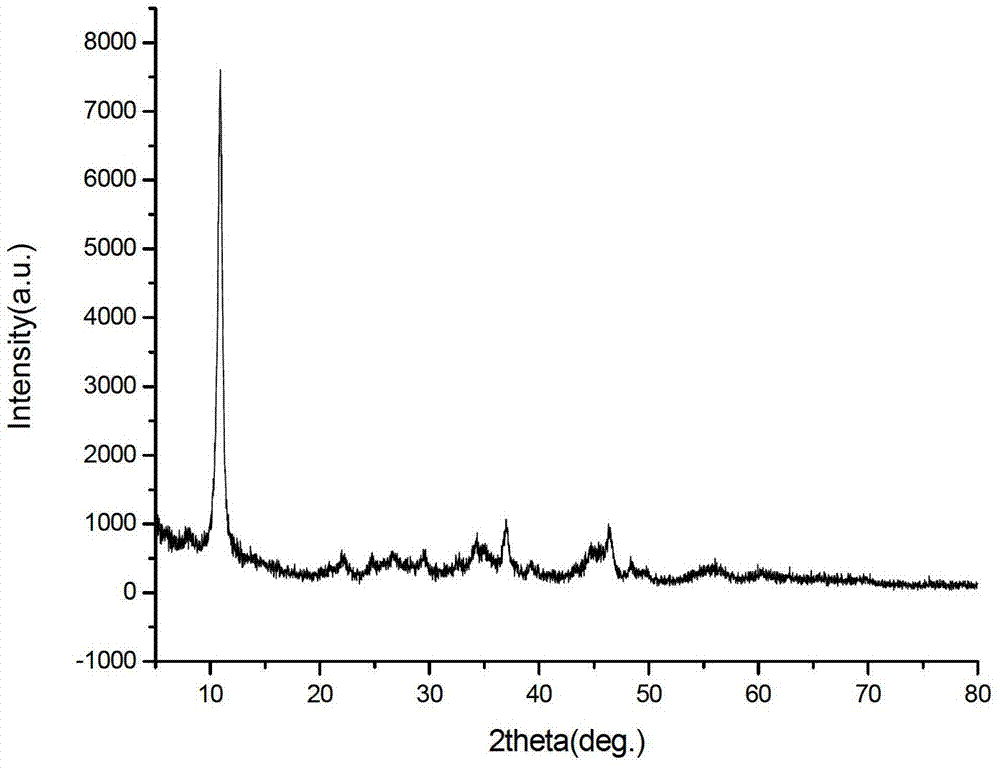

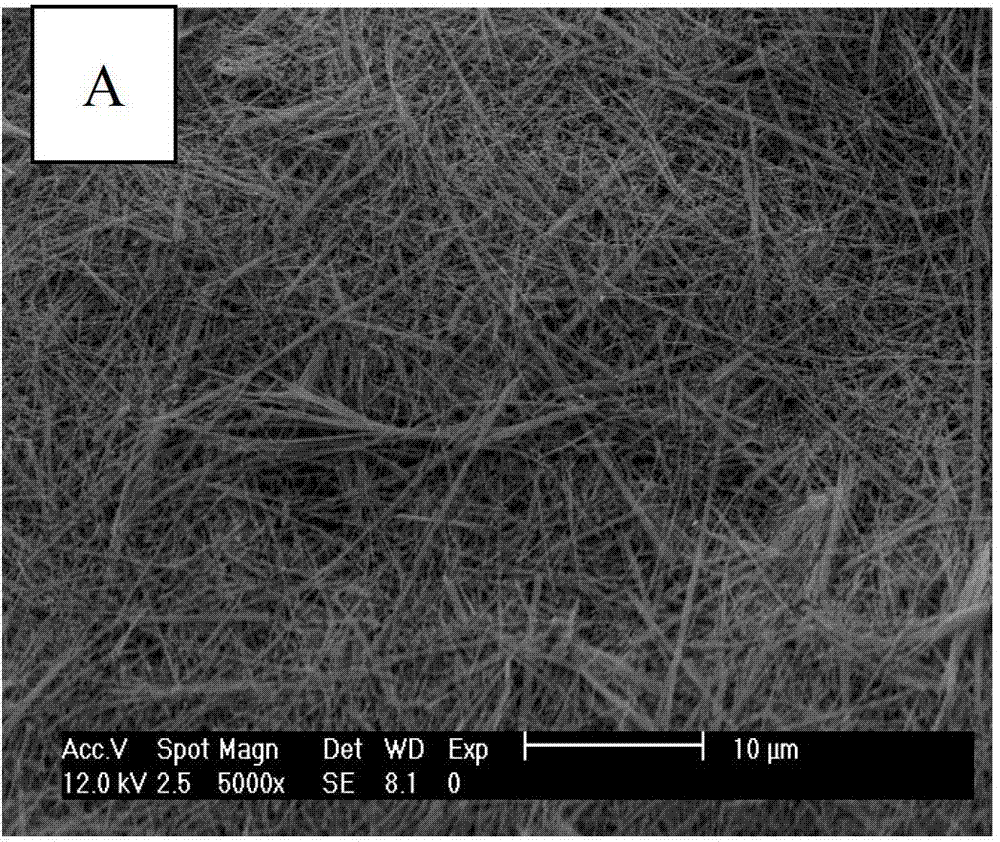

Embodiment 1

[0028] Inject 30ml of 5M NaOH solution prepared in advance into a 50mL autoclave (lined with PTFE 316 stainless steel), and then add 0.2gTiO 2 Nanopowder ((P25, Degussa), ultrasonically made TiO 2 The powder is evenly dispersed, then sealed, and hydrothermally reacted in a furnace temperature of 160°C (constant temperature drying box) for 24 hours. After cooling, pour off the supernatant to obtain a white precipitate, which contains self-grown sodium titanate nanowires . Firstly, the white precipitate rich in sodium titanate nanowires is repeatedly washed with distilled water, dilute hydrochloric acid (pH=2), and distilled water until neutral to generate titanate nanowires. After being collected by filtration, they are calcined in a muffle furnace with a temperature gradient of 2-5°C / min, and heat-treated in a furnace at 650°C for 2 hours to obtain the required samples.

Embodiment 2

[0030] Inject 300ml of 15M NaOH solution prepared in advance into a 500mL autoclave (lined with PTFE 316 stainless steel), and then add 6gTiO 2 Nanopowder ((P25, Degussa), ultrasonically made TiO 2 The powder is evenly dispersed, then sealed, and hydrothermally reacted in a furnace temperature of 250°C (constant temperature drying box) for 7 days. After cooling, pour off the supernatant to obtain a white precipitate, which contains self-grown sodium titanate nanowires . Firstly, the white precipitate rich in sodium titanate nanowires is repeatedly washed with distilled water, dilute hydrochloric acid (pH=1), and distilled water until neutral to generate titanate nanowires. After being collected by filtration, it is calcined in a muffle furnace with a temperature gradient of 2-5°C / min, and heat-treated in a furnace at 800°C for 2 hours to obtain the desired sample.

[0031] Embodiment 1, 2 all can obtain specific surface area and be 35.2m 2 / g, candied haws-shaped nanowires ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com