Process method for separating and purifying cresol mixed isomers

A technology of isomers and cresols, applied in the field of chemical separation, can solve the problems of large amount of desorbent, high production cost, and high cost, and achieve the effects of simple operation steps, improved production efficiency, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

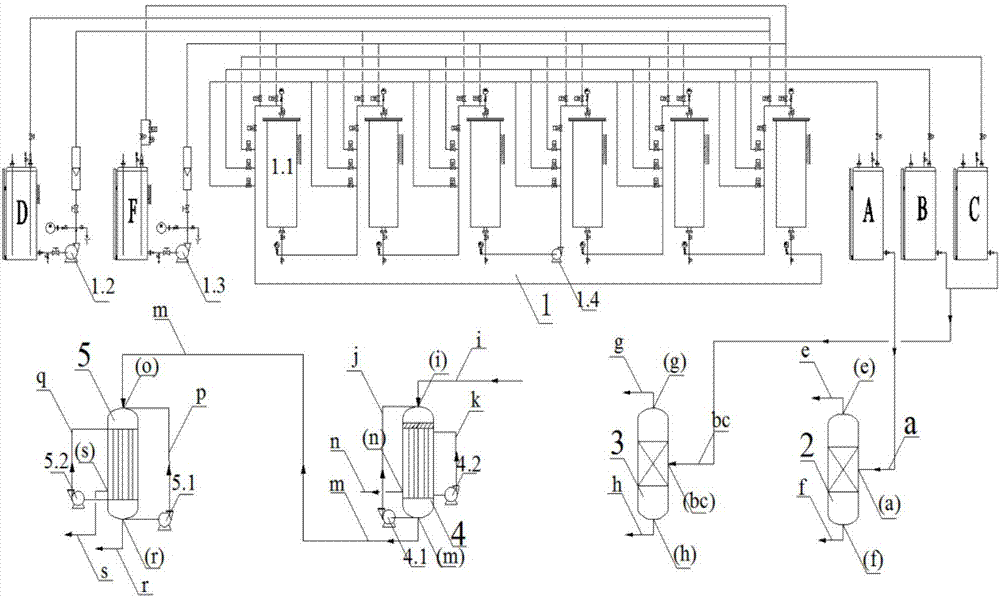

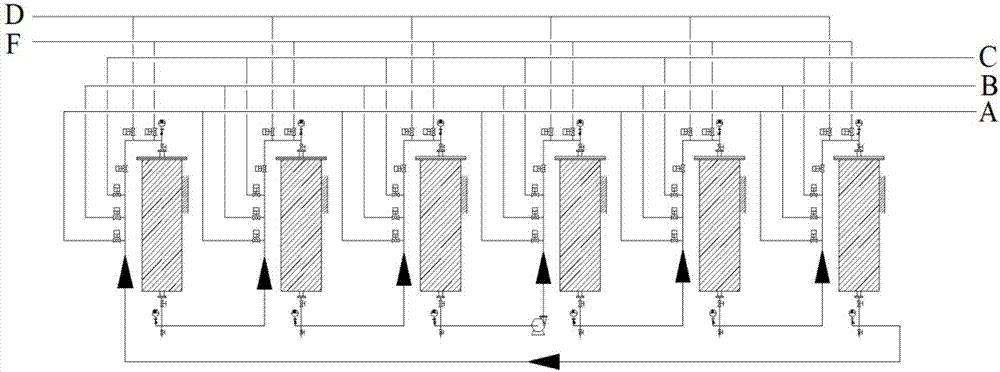

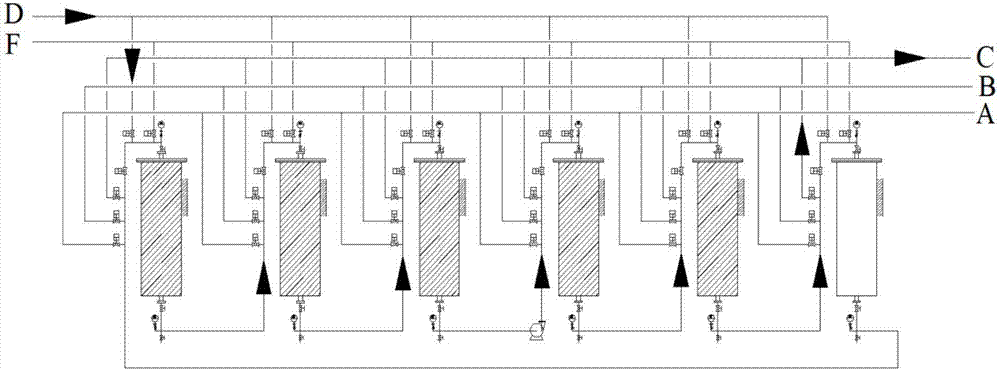

Method used

Image

Examples

Embodiment 1

[0040] 102kg water content 15wt% average particle diameter is 0.45 μ m silicon-aluminum molecular ratio is the X molecular sieve of 2.37, and 10.5kg kaolin (90.2wt% of kaolinite content) is binding agent, and deionized water is auxiliary agent (deionized water quality is solid 10.9wt% of the powder) is rolled into balls to obtain balls of 0.3-0.8 mm, dried at 120° C. for 24 hours, and calcined at 550° C. for 6 hours. The pellets were treated with 1.4 mol / L NaOH aqueous solution at a solid-to-liquid ratio of 1.6:1 at 95°C for 6 hours. Wash the pellets with deionized water until the pH value is 10, then dry them at 85°C for 24 hours, roast them at 550°C for 6 hours, and screen out pellets of 0.3-0.8 mm in size, then fluidize and dehydrate them at 240°C to control the water content of the adsorbent. 1.8wt%, the obtained adsorbent is recorded as I. Prepare a 3mL cylindrical cylinder, add 2.5mL of adsorbent sample into the cylinder, apply pressure at a strength of 200N, and count ...

Embodiment 2

[0042] The preparation process is the same as that of Example 1, except that rectorite is used as a binder to form a rolling ball, and the adsorbent II is obtained after post-treatment. The component contents and physical properties are shown in Table 1.

Embodiment 3

[0044] The preparation process is the same as in Example 1, and the adsorbent obtained in Example 1 is subjected to 0.5mol / L of KNO 3 Aqueous solution, at 95°C, 0.2MPa, exchange liquid volume space velocity 3.0h -1 K + exchanged for 20h, and then subjected to 0.18mol / L Ba(NO 3 ) 2 The aqueous solution was replaced under the same conditions for 24h, after the exchange K + 4.1% of total cationic sites, Ba 2+ Accounting for 95.5% of the total cationic sites, it is adsorbent III, and its component content and physical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com