Treatment method and system for organic exhaust gas generated from chlorination reaction

A technology of organic waste gas and chlorination reaction, applied in gas treatment, chemical instruments and methods, gaseous effluent wastewater treatment, etc., can solve problems such as pollution, high cost of lye absorption, and a large amount of high-concentration wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

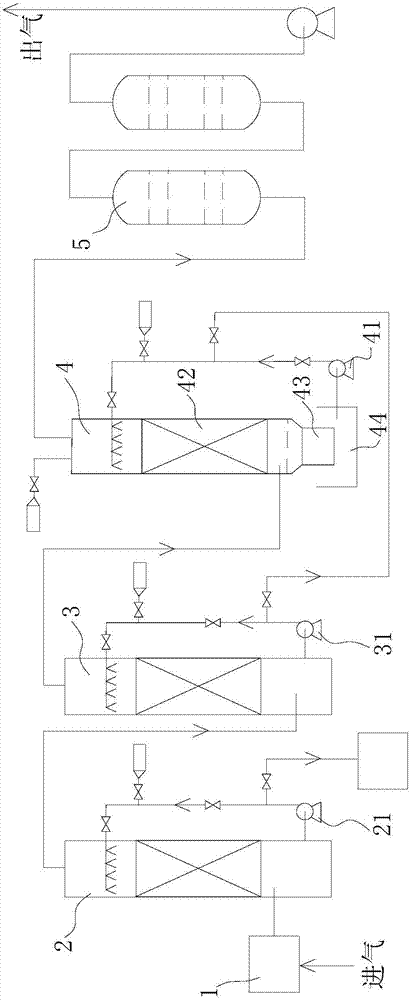

Image

Examples

Embodiment 1

[0069] The 5-chloro-2-aminobenzoic acid used in the synthesis of the important intermediate 2-chloro-3-amino-4-picoline of the anticancer drug nevirapine (nevirapine) is made of aminobenzoic acid as raw material through chlorine gas Chlorinated synthetically.

[0070] A plant of aminobenzoic acid produced a large amount of waste gas containing chlorine, hydrogen chloride, aminobenzoic acid, and chloroaminobenzoic acid through a high-temperature chlorination process. The content of each substance is about: chlorine gas 34000mg / m 3 , hydrogen chloride 56000mg / m 3 , organic matter 8000mg / m 3 . The above waste gas is 500m 3 The flow rate of / h enters the condenser, and the condensation temperature is -5°C;

[0071] The condensed exhaust gas enters the water washing tower, and is absorbed countercurrently with clean water from the top of the tower, and the spray density is 40m 3 / (m 2 h), the waste gas residence time is 5s, and the absorption temperature is 35°C; the chlorin...

Embodiment 2

[0081] 2,6-Dichlorobenzonitrile is an intermediate of various herbicides and insecticides. The intermediate of a 2,6-dichlorobenzonitrile project in a factory produced a large amount of waste gas containing chlorine, hydrogen chloride, and chlorobenzene through the chlorination process. . The content of each substance is about: chlorine gas 12000mg / m 3 , hydrogen chloride 2000mg / m 3 , organic matter 1000mg / m 3 .

[0082] Exhaust gas at 500m 3 The flow rate of / h enters the condenser, and the condensation temperature is -10°C; the washing liquid contains hydrochloric acid, and the hydrochloric acid can be recovered when the hydrochloric acid in the washing liquid reaches 12%;

[0083] The condensed exhaust gas enters the water washing tower, and is absorbed in parallel flow with clean water from the top of the tower, with a spray density of 42m 3 / (m 2 h), the waste gas residence time is 8s, the absorption temperature is 35°C; the chlorine content after absorption is abou...

Embodiment 3

[0091] As an important chemical raw material, p-chlorobenzaldehyde, a dye intermediate, is usually produced by chlorination and hydrolysis of p-chlorotoluene.

[0092] A factory of p-chlorobenzaldehyde produced a large amount of waste gas containing chlorine, hydrogen chloride, chlorobenzene, and benzyl chloride through the chlorination process. The content of each substance is about: chlorine gas 22000mg / m 3 , hydrogen chloride 16000mg / m 3 , organic matter 6000mg / m 3 .

[0093] Exhaust gas at 500m 3 The flow rate of / h enters the condenser, and the condensation temperature is -7°C;

[0094] The washing liquid contains hydrochloric acid, and the hydrochloric acid can be recovered when the hydrochloric acid in the washing liquid reaches 14%;

[0095] The condensed exhaust gas enters the water washing tower, and is absorbed in parallel flow with clean water from the top of the tower, and the spray density is 35m 3 / (m 2 h), the waste gas residence time is 6s, the absorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com