Organic waste gas adsorbing recovery device and process

A technology of waste gas and adsorption tower, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of activated carbon adsorbents, such as inflammability, potential safety hazards, and high technical energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

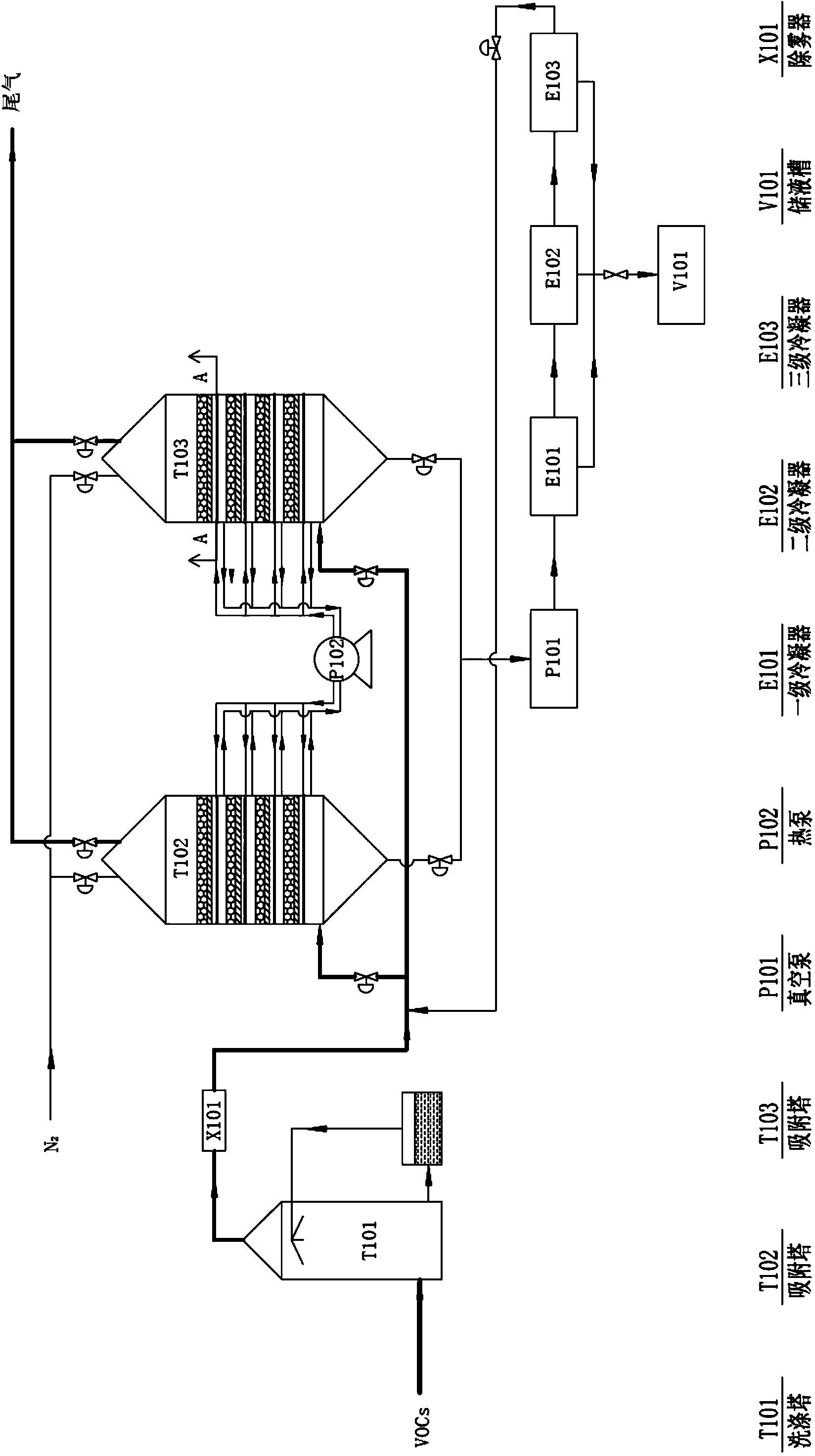

[0049] Refer below figure 1 , figure 2 and image 3 Provide the device system and schematic flow sheet of process technology of the present invention, device of the present invention comprises two polymer resin adsorption towers, as figure 1 As shown, they are the first polymer resin adsorption tower T102, the second polymer resin adsorption tower T103; and vacuum pump P101, heat pump P102, primary condenser E101, secondary condenser E102, tertiary condenser E103, liquid storage Tank V101, scrubber T101, demister X101.

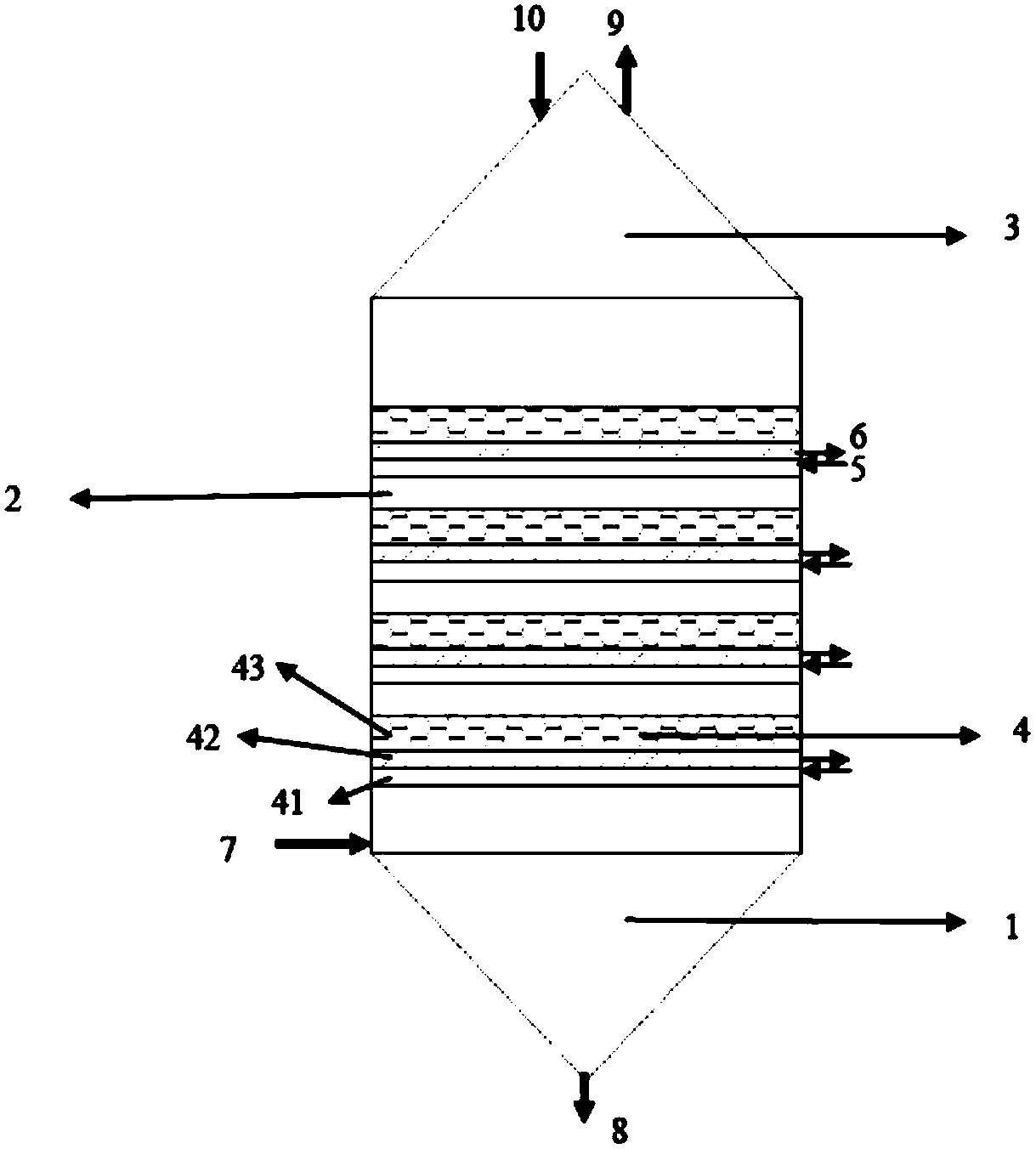

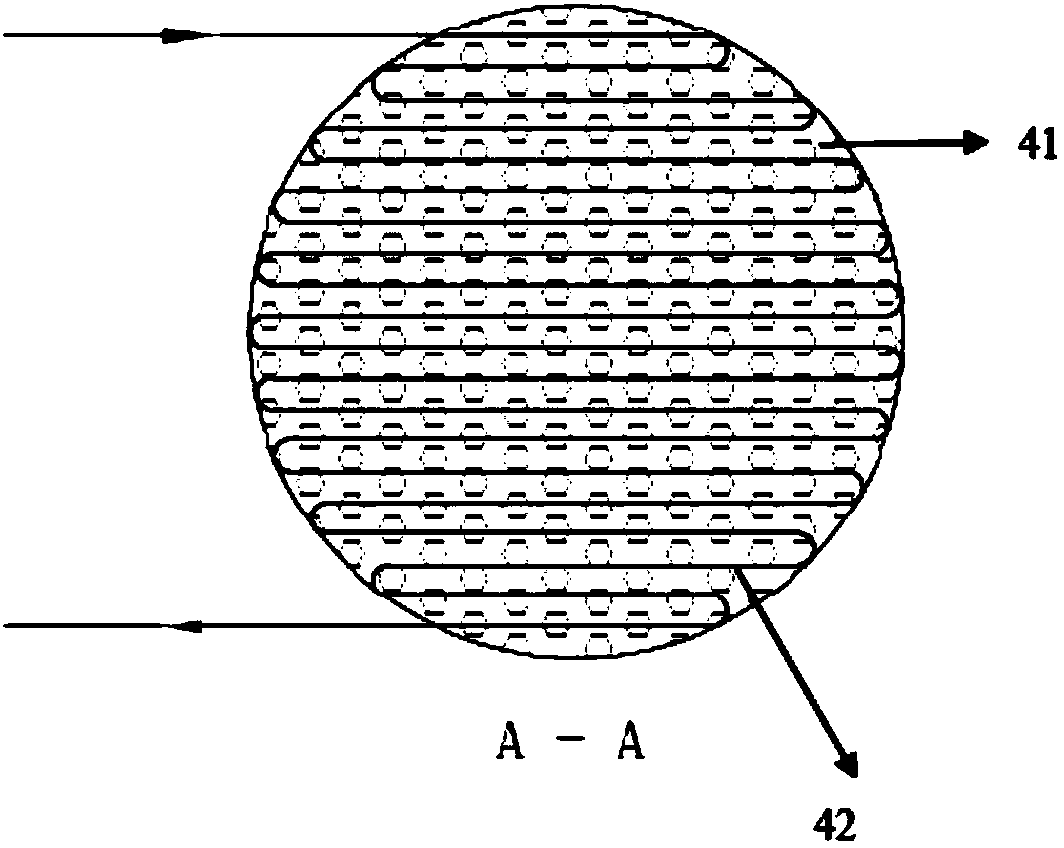

[0050]The internal structure of the first polymer resin adsorption tower T102 and the second polymer resin adsorption tower T103 is the same, and the cross-sectional view is as follows figure 2 As shown, there are waste gas entry area 1, purification area 2 for gas adsorption and purification, and purification gas discharge area 3 from bottom to top. The purification area 2 is arranged with a horizontally laid adsorption layer 4, and the adsorption layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com