Method for recycling alkali treatment lignocellulose waste fluid

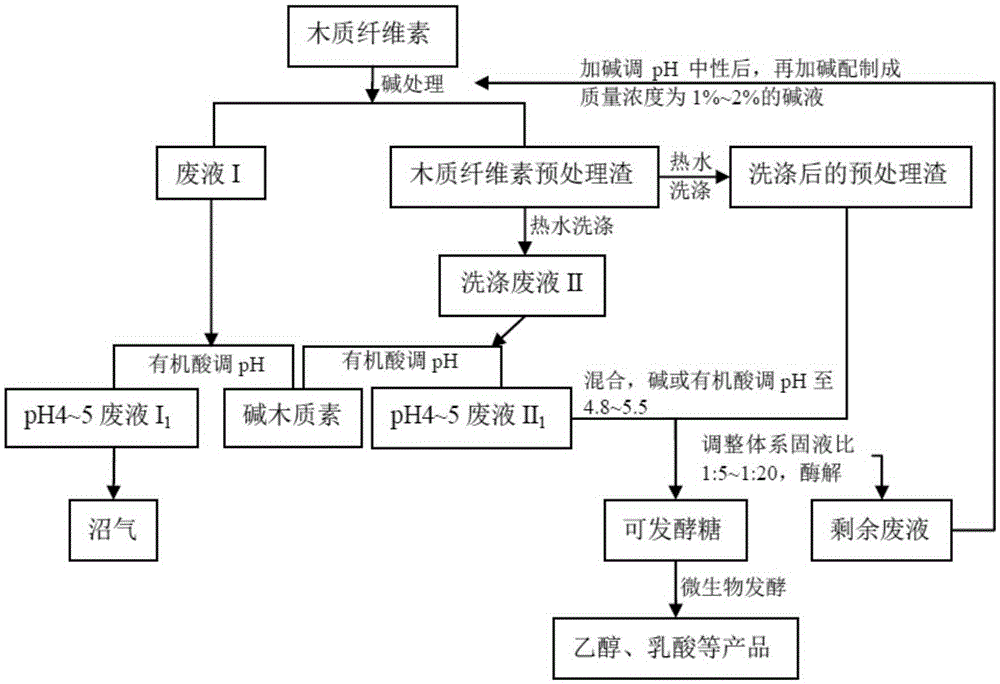

A technology for recycling lignocellulose and waste liquid, which is applied in the field of waste resource utilization and environmental protection, can solve problems such as unfavorable industrial application and environmental pollution, and achieve the advantages of reuse, reduction of water consumption, and reduction of process operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for recycling lignocellulose waste liquid by alkali treatment, comprising the following steps:

[0027] (1) Take bagasse that has been sieved to 40-60 meshes and put it in the reaction kettle, add a 2% NaOH solution with a mass concentration of 2% at a solid-to-liquid ratio of 1:10 (g absolute dry material / mL), at 60°C and 100rpm After processing for 3h, adopt the method of filtration to carry out solid-liquid separation, collect alkali treatment waste liquid I and lignocellulose treatment residue;

[0028] (2) Add water to the reaction kettle, use the residual heat of the kettle body to preheat the hot water to 40°C, and wash the lignocellulose treatment residue in step 1 with water at a solid-to-liquid ratio of 1:10 (g absolute dry material / mL) for 3 times, Collect waste washing liquid II;

[0029] (3) adjust the pH of waste liquid I and waste liquid II with acetic acid to be 4.0 respectively, alkali lignin is separated out, and adopts the centrifugal method...

Embodiment 2

[0033] A method for recycling lignocellulose waste liquid by alkali treatment, comprising the following steps:

[0034] (1) Take bagasse that has been sieved to 40-60 meshes and put it in the reaction kettle, add a NaOH solution with a mass concentration of 1.5% at a solid-to-liquid ratio of 1:15 (g absolute dry material / mL), and put it under the conditions of 70°C and 100rpm After processing 2.5h, adopt the method for filtering to carry out solid-liquid separation, collect alkali treatment waste liquid I and lignocellulose treatment residue;

[0035] (2) Add water to the reaction kettle, use the residual heat of the kettle body to preheat the hot water to 45°C, and wash the lignocellulose treatment residue in step 1 with water at a solid-to-liquid ratio of 1:8 (g absolute dry material / mL) for 4 times, Collect waste washing liquid II;

[0036] (3) Use acetic acid to adjust the pH of waste liquids I and II to 4.0, and the alkali lignin is separated out, and the solid-liquid se...

Embodiment 3

[0040] A method for recycling lignocellulose waste liquid by alkali treatment, comprising the following steps:

[0041](1) Take the bagasse that has been sieved to 40-60 meshes and place it in the reaction kettle, add a 1% NaOH solution with a mass concentration of 1% at a solid-to-liquid ratio of 1:20 (g absolute dry material / mL), and put it under the conditions of 80°C and 100rpm After processing for 2h, adopt the method of filtration to carry out solid-liquid separation, collect alkali treatment waste liquid I and lignocellulose treatment residue;

[0042] (2) Add water to the reaction kettle, use the residual heat of the kettle body to preheat the hot water to 50°C, and wash the lignocellulose treatment residue in step 1 with water at a solid-to-liquid ratio of 1:5 (g absolute dry material / mL) for 4 times, Collect waste washing liquid II;

[0043] (3) Use acetic acid to adjust the pH of waste liquids I and II to 4.0, and the alkali lignin is separated out, and the solid-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com