Flue gas dust collector

A dust collector and flue gas technology, applied in chemical instruments and methods, using liquid separation agents, separation devices, etc., can solve the problems of unsatisfactory filtration effect, low recycling rate, high cost, etc., and achieve improved dust removal effect, High dust removal efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

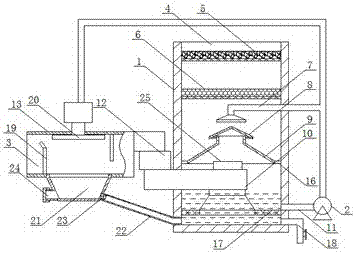

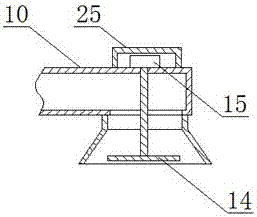

[0015] A kind of flue gas deduster of the present invention is made up of spray tower 1, pump body 2, air inlet 3 and air outlet 4, and the top of its described spray tower 1 is air outlet 4, and inside spray tower 1 The cavity is provided with a first activated carbon layer 5, a second activated carbon layer 6, a spray pipe 7, a liquid cap 8, a diversion cover 9 and an air inlet pipe 10 in sequence from top to bottom, and the lower part of the spray tower 1 is provided with a liquid outlet pipe. 11 communicates with the inlet of the pump body 2, the inlet end of the air intake pipe 10 is connected with the blower fan 12 and the primary spray box 13 in turn, the other end of the primary spray box 13 is the air inlet 3, and the outlet pipeline of the pump body 2 is connected with the The spray pipe 7 is connected, and the end of the spray pipe 7 is equipped with a mist distributor 14, and the other outlet pipeline of the pump body 2 is connected with the primary spray tank 13, a...

Embodiment 2

[0017] A kind of flue gas deduster of the present invention is made up of spray tower 1, pump body 2, air inlet 3 and air outlet 4, and the top of its described spray tower 1 is air outlet 4, and inside spray tower 1 The cavity is provided with a first activated carbon layer 5, a second activated carbon layer 6, a spray pipe 7, a liquid cap 8, a diversion cover 9 and an air inlet pipe 10 in sequence from top to bottom, and the lower part of the spray tower 1 is provided with a liquid outlet pipe. 11 communicates with the inlet of the pump body 2, the inlet end of the air intake pipe 10 is connected with the blower fan 12 and the primary spray box 13 in turn, the other end of the primary spray box 13 is the air inlet 3, and the outlet pipeline of the pump body 2 is connected with the The spray pipe 7 is connected, and the end of the spray pipe 7 is equipped with a mist distributor 14, and the other outlet pipeline of the pump body 2 is connected with the primary spray tank 13, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com