Oxidation-adsorption integral arsenic removal device and method for drinking water

A drinking water and adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of high production costs, reduce treatment costs, reduce floor space, and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

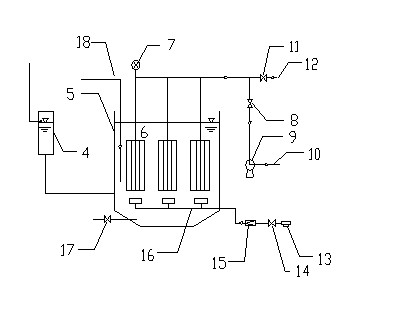

[0054] Such as figure 1 As shown, an oxidation adsorption integrated drinking water arsenic removal device includes a water inlet control system, a reactor 5, an ultrafiltration membrane filtration system 6, and also includes an aeration oxidation system, a mud discharge system and an outlet water control system. The water inlet control system is connected to the reactor 5; the ultrafiltration membrane filtration system 6 is located at the middle and lower part of the reactor 5, and is connected with the water outlet control system; the sludge discharge system includes a sludge discharge valve 17 and a sludge discharge valve. Pipe, mud discharge valve 17 is located on the mud discharge pipe, is used to control the opening and closing of the mud discharge pipe, and one end of the mud discharge pipe is connected to the bottom half of the reactor 5 or the lower half of the reactor 5 side walls; the aeration Oxidation system comprises aeration pipe 16, air inlet valve 14 and air p...

Embodiment 2

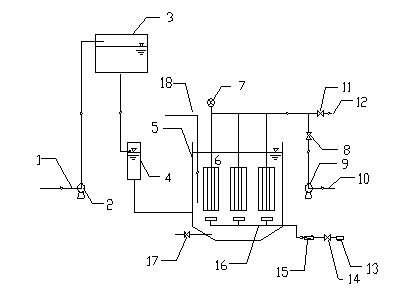

[0064] Such as figure 2 As shown, an oxidation adsorption integrated drinking water arsenic removal device includes a water inlet control system, a reactor 5, an ultrafiltration membrane filtration system 6, and also includes an aeration oxidation system, a mud discharge system and an outlet water control system. The water inlet control system is connected to the reactor 5; the ultrafiltration membrane filtration system 6 is located at the middle and lower part of the reactor 5, and is connected with the water outlet control system; the sludge discharge system includes a sludge discharge valve 17 and a sludge discharge valve. Pipe, mud discharge valve 17 is located on the mud discharge pipe, is used to control the opening and closing of the mud discharge pipe, and one end of the mud discharge pipe is connected to the bottom half of the reactor 5 or the lower half of the reactor 5 side walls; the aeration Oxidation system comprises aeration pipe 16, air inlet valve 14 and air ...

Embodiment 3

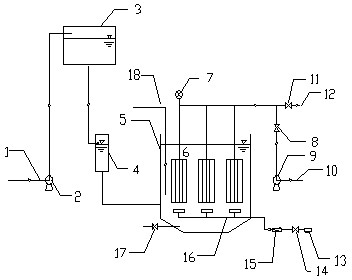

[0079] Same as Example 2, the difference is that the arsenic-contaminated drinking water to be treated contains 0.8 mg / L of arsenic, the oxidant is a mixed gas of air and ozone, wherein the volume of air accounts for 99%, and the gas-water ratio is 40:1; The adsorbent is powdered iron oxide, the particle size is 100 microns to 250 microns, the dosage is 180 mg / L, and the reaction time in the reactor 5 is 15 minutes; the suction pressure of the suction pump 9 is in the range of 20 kPa to 30 kPa, The ultrafiltration membrane filtration system 6 adopts the submerged hollow fiber ultrafiltration membrane provided by Jiangsu Yongtai Environmental Protection Technology Co., Ltd., the membrane pore size is 0.02 microns, and the membrane material is polyvinyl chloride. The water flux of the ultrafiltration membrane is 35L / m 2 ·h; After 20d, open the sludge discharge valve 17 to discharge the saturated adsorbent in the reactor 5.

[0080] Compared with the previous fixed bed treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com