Method for sealing ultra-thin shadow mask plasma display

A plasma display screen and shadow mask technology, which is applied in the manufacture of discharge tubes/lamps, electrical components, cold cathodes, etc., can solve the problems of low sealing success rate of ultra-thin plasma display screens, achieve uniform force, improve Stability, effect of avoiding bumps and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this example, we use the above method to complete the sealing of a 50mm×50mm phosphor-free pure Ne monochrome ultra-thin shadow mask display. The thickness of the ultra-thin glass is 50 μm. The first thick glass 1 and the second thick glass 3 are The PD200 glass with high flatness has an area of 100mm×100mm and a thickness of 1.1mm. The specific steps are as follows:

[0028] Step 1: Clean the first thick glass 1, the second thick glass 3 and the shadow mask with ultrasonic waves, and dry them;

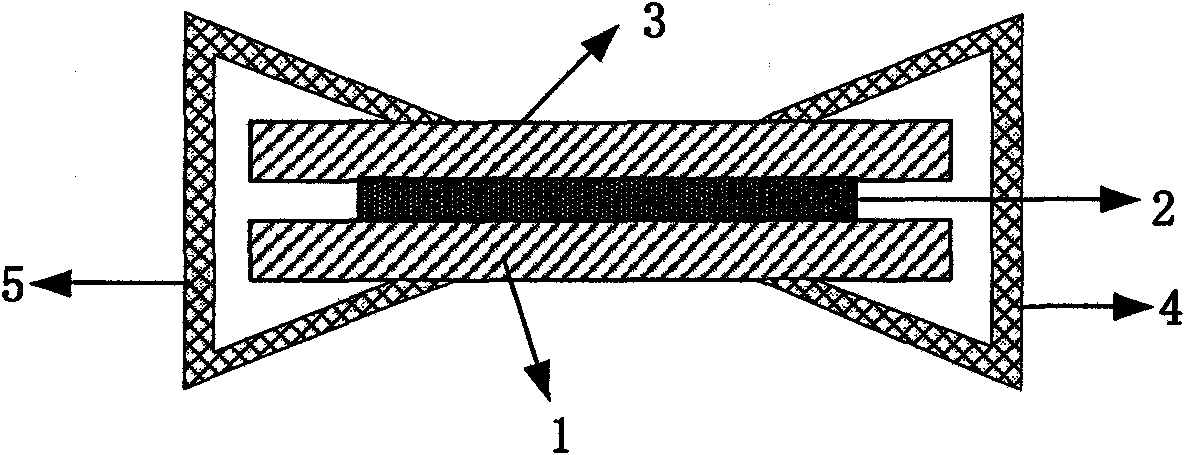

[0029] Step 2 Place a shadow mask 2 with a size of 31.5mm×31.5mm between the first thick glass 1 and the second rear glass 3 to form a pre-fired assembly, and use the first sealing clip 4 and the second sealing clip 5 to seal the pre-fired The burning assembly is fixed;

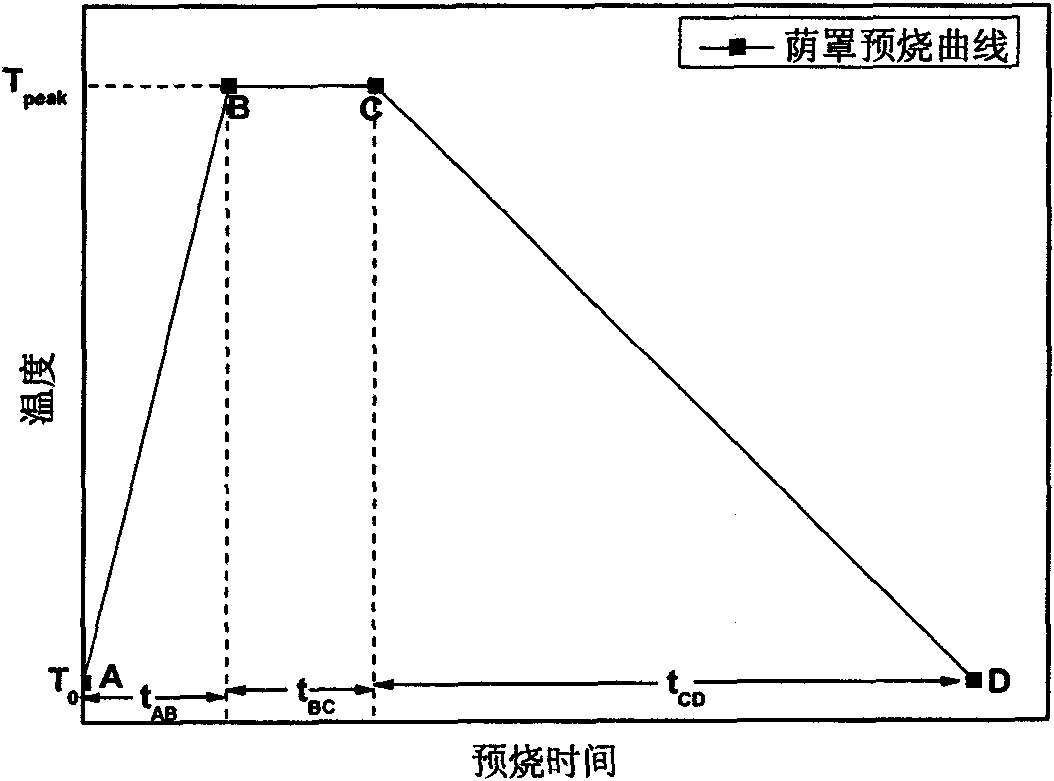

[0030] Step 3 Put the fixed pre-fired assembly into a vacuum of 8×10 -5 In the sealing furnace of Pa, the initial temperature T 0 The room temperature is 25°C, according to the pre-burning curve, enter...

Embodiment 2

[0035] In this example, we use the above method to complete the sealing of 50mm×50mm ultra-thin shadow mask display screen with phosphor Ne+10% Xe green powder. The ultra-thin glass thickness is 50μm, the first thick glass 1 and the second thick glass Glass 3 uses PD200 glass with high flatness, the area is 100mm×100mm, and the thickness is 1.1mm. The specific steps are as follows:

[0036] Steps 1, 2, 3, and 4 are the same as steps 1, 2, 3, and 4 in Example 1;

[0037] Step 5: Coat the pretreated shadow mask 2 with green fluorescent powder, and bake the shadow mask 2 coated with the fluorescent powder at a temperature of 450° C., and the baking time is half an hour;

[0038] Step 6 is the same as Step 5 in Implementation Example 1;

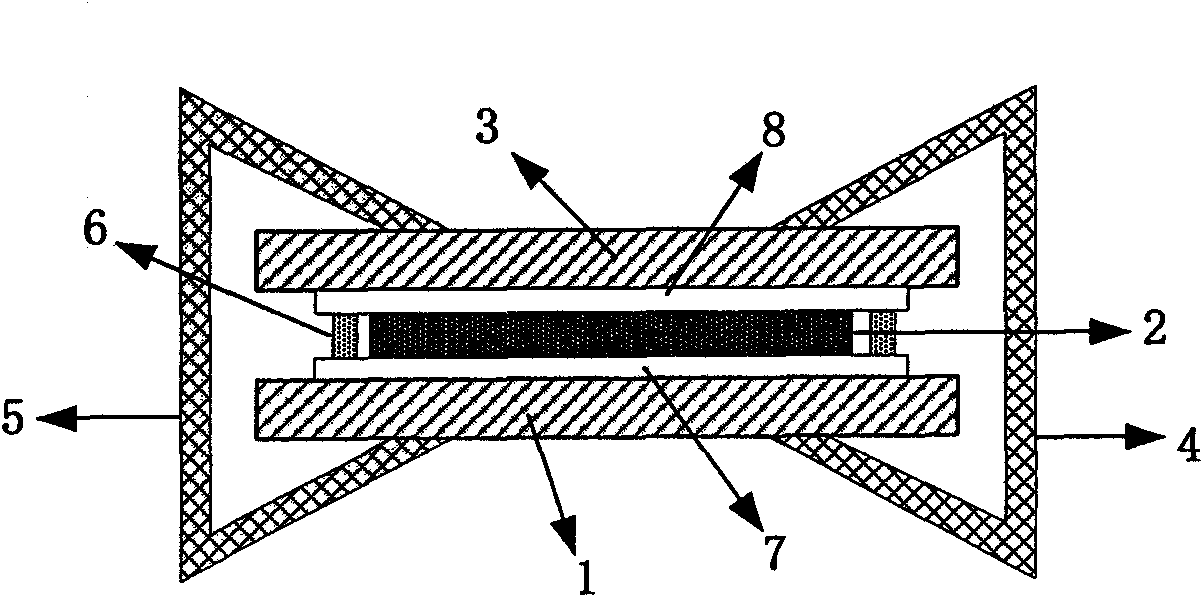

[0039] Step 7 Attach the front substrate 8 of the ultra-thin screen and the rear substrate 7 coated with the sealing frame 6 of low-melting glass on the top and bottom of the pre-fired and cleaned shadow mask, and place them on the first thick gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com