Trace in-situ carbon-induced Si3N4 heat-conducting ceramic material and preparation method thereof

A heat-conducting ceramic, in-situ technology, applied in the field of ceramic materials, can solve the problems of reducing density, uneven distribution of carbon, increasing loss value, etc., to achieve the effect of reducing glass phase, reducing environmental pollution, and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

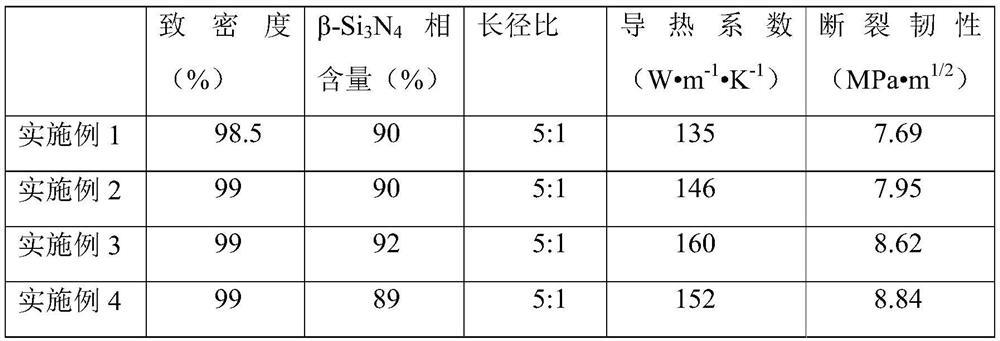

Examples

Embodiment 1

[0029] This example provides a trace in situ carbon-induced Si 3 N 4 A method for preparing a heat-conducting ceramic material, specifically comprising the following steps:

[0030] S1. Modification: Si 3 N 4 The powder is pickled in an acidic solution with a concentration of 3% HNO 3 And concentration is 3% HCl according to 1:1 configuration, then the powder of sedimentation and sintering aid (3wt% Y 2 o 3 and 5wt% MgO) in an alkaline solution for ball milling and aging. The alkaline solution is a 5% NaOH solution. Finally, the powder is washed with deionized water and dried to obtain modified Si 3 N 4 Mix powder with sintering aid;

[0031] S2. Molding: Add organic matter to the mixed powder obtained in step S1 and mix evenly, wherein the amount of organic matter is (relative to Si 3 N 4 Powder mass) 4wt%, organic matter is made by stirring evenly by 1wt% polyethylene glycol, 1.5wt% polyvinyl alcohol, 1wt% polyester, 0.5wt% polyamide according to mass ratio; Then th...

Embodiment 2

[0035] This example provides a trace in situ carbon-induced Si 3 N 4 A method for preparing a heat-conducting ceramic material, specifically comprising the following steps:

[0036] S1. Modification: Si 3 N 4 The powder is pickled in an acidic solution with a concentration of 4% HNO 3 solution, and then the settled powder and sintering aid (3wt% of Y 2 o 3 and 5wt% MgO) in an alkaline solution for ball milling and aging, and the alkaline solution has a concentration of 8% NH 4 OH solution, and finally the powder was washed with deionized water and then dried to obtain modified Si 3 N 4 Mix powder with sintering aid;

[0037] S2. Molding: Add organic matter to the mixed powder obtained in step S1 and mix evenly, wherein the amount of organic matter (relative to Si 3 N 4 Powder mass) is 5%wt, and the organic matter is made by stirring evenly according to the mass ratio of 1.5wt% polyethylene glycol, 1wt% polyacrylonitrile, and 2.5wt% polyvinyl alcohol; then the mixture...

Embodiment 3

[0041] This example provides a trace in situ carbon-induced Si 3 N 4 A method for preparing a heat-conducting ceramic material, specifically comprising the following steps:

[0042] S1. Modification: Si 3 N 4 The powder is pickled in an acidic solution with a concentration of 4% HNO 3 And concentration is 3% HCl according to 1:1 configuration, then the powder of sedimentation and sintering aid (3wt% Y 2 o 3 and 5wt% MgO) in an alkaline solution for ball milling and aging. The alkaline solution is a 4% NaOH solution. Finally, the powder is washed with deionized water and dried to obtain modified Si 3 N 4 Mix powder with sintering aid;

[0043] S2. Molding: Add organic matter to the mixed powder obtained in step S1 and mix evenly, wherein the amount of organic matter (relative to Si 3 N 4 Powder mass) is 5%wt, and the organic matter is made by stirring evenly according to the mass ratio of 1.2wt% polyethylene glycol, 1.5wt% polyethylene, and 1.3wt% polyamide; then the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com