Plasma processing technique for reducing MOCVD TiN film thickness on through-hole side wall

A plasma and processing technology, applied in the field of integrated circuit chip manufacturing, can solve the problems of increased interconnect resistance, high film, CD loss, etc., and achieve the effect of reducing device damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

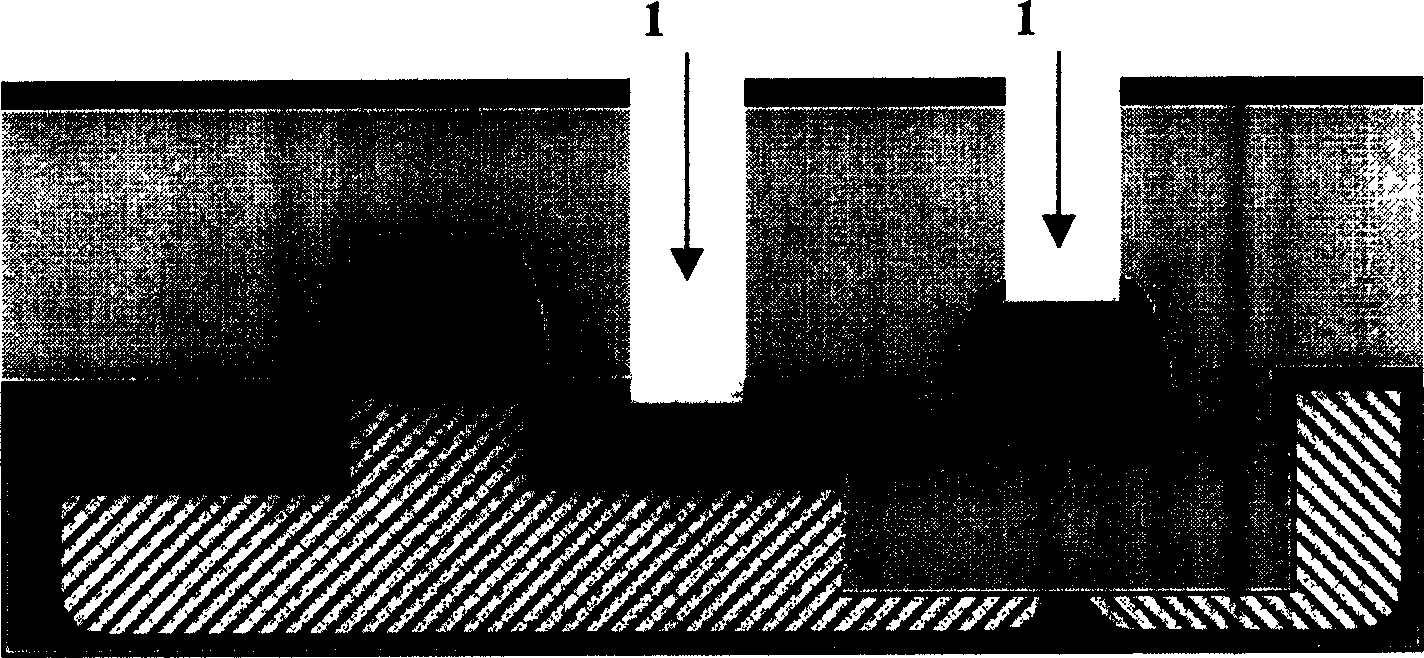

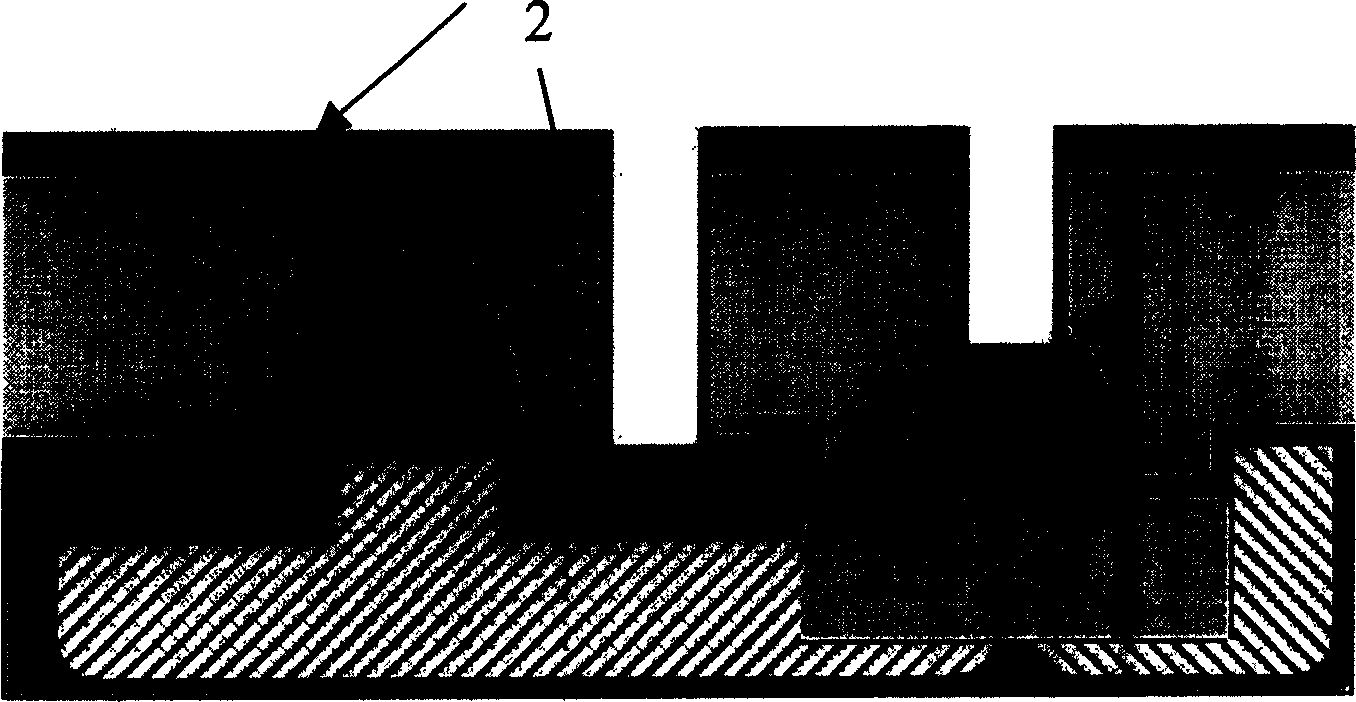

[0030] The implementation steps of this technology are as follows:

[0031] 1. Etching and cleaning of metal interconnection holes on silicon wafers;

[0032] 2. Deposition of MOCVD TiN film;

[0033] 3. After completion, continue with plasma post-processing. The process steps are: the CVD chamber is fed with N 2 、H 2 and Ar, boosted to 5, 10 or 15 Tor; H 2 :N 2 : Ar=1:1:0.01 or H 2 :N 2 : Ar=1:3:0.001; the gas plasmaization power is controlled at 400, 500 or 750W; the processing time can be between 10 and 20S;

[0034] 4. After step 1 is completed, exhaust the reaction chamber to 10mT;

[0035] 5. Continue to step 3;

[0036] 6. After completing step 5, exhaust the system to 10-7mT;

[0037] 7. The equipment is restored to the state of waiting for manufacture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com