Double-stage slaking device for calcium hydroxide production

A calcium hydroxide and digestion tank technology, applied in the field of process production lines, can solve the problems of easy pollution of the environment, low production capacity, and low efficiency, and achieve the effects of preventing environmental pollution, improving the purity of finished products, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

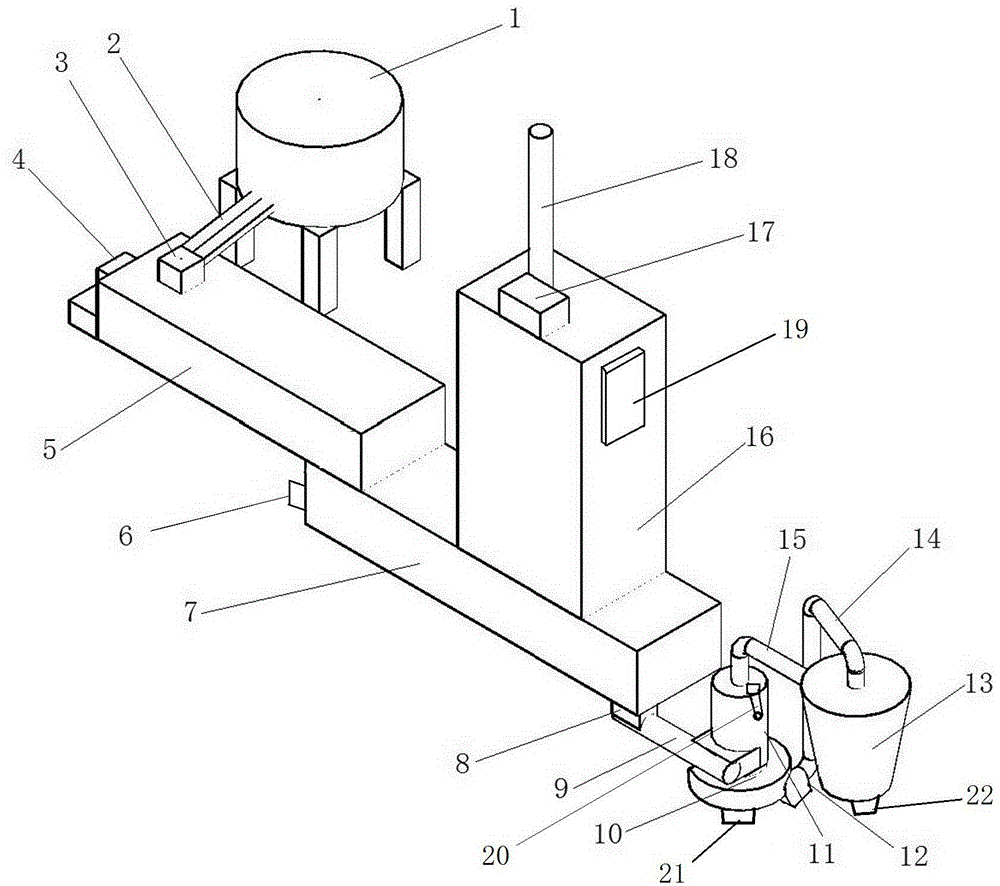

[0031] Embodiment 1, the two-stage digestion device produced by calcium hydroxide according to the present invention is connected by the raw material bin 1 through the raw material input channel 2 and the raw material inlet 3 sealed and installed on the top of the first-level digestion tank 5, and the raw material The input channel 2 is provided with a metering device; the discharge port of the airtight primary digestion tank 5 is sealed and connected with the feed port of the secondary digestion tank 7, and a dehumidification collection device 16 is installed on the upper part of the middle waist of the secondary digestion tank 7 , the secondary discharge interface 8 of the secondary digestion tank 7 is sealed and connected with the discharge pipe 9, and a screw propulsion device is arranged in the discharge pipe 9, and the other end of the discharge pipe 9 is connected to the inlet of the sorting machine 11 The lower part of the sorter 11 is provided with a mill 10 in a seale...

Embodiment 2

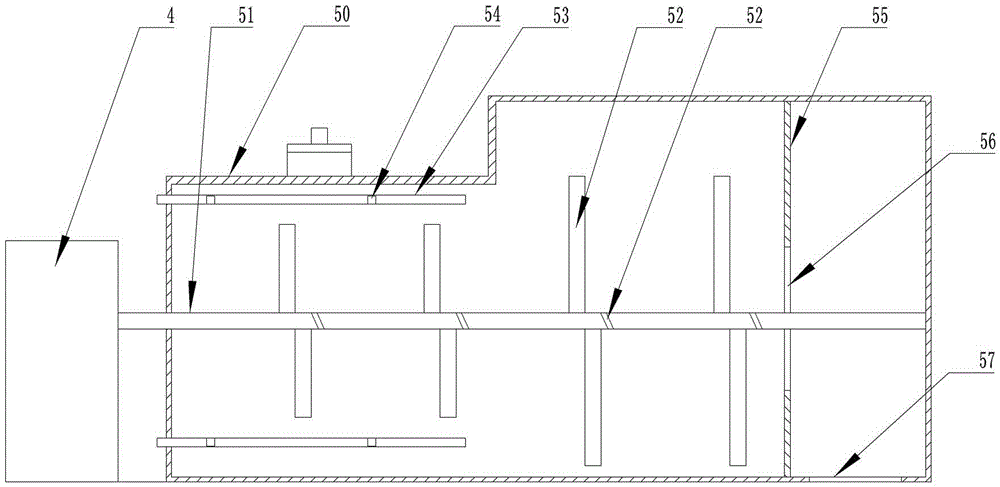

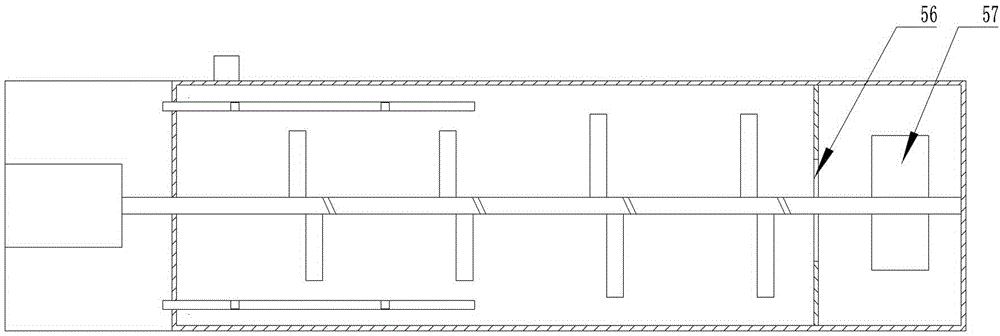

[0034] Embodiment 2, the primary digestion tank 5 of the present invention includes a primary power unit 4, a primary digestion tank body 50, a primary transmission shaft 51, a transmission blade 52, and a spray pipe 53, before the primary digestion tank body 50 One or more spray pipes 53 are respectively arranged on both sides of the head, and more than three spray ports 54 are arranged on the spray pipes 53; 51 is provided with more than 3 transmission blades 52, and each transmission blade becomes oblique and vertically fixed on the primary transmission shaft 51, so that it forms a backward thrust when rotating; the outer end of the primary transmission shaft 51 is arranged on the The first-level power unit 4 outside the first-level digestion tank body 50 is connected; the rear portion of the first-level digestion tank body 50 is provided with a first-level baffle plate 55, and the middle part of the first-level baffle plate 55 is provided with a first-level baffle plate fee...

Embodiment 3

[0035] Embodiment 3, the hot air discharged from the dehumidification collection device 16 of the present invention enters the heat conversion system after being dedusted by the dust collector, and transfers the heat to the spray water source of the spray system, so that the spray water is supplied to the spray pipe 53, so that The spray water has a higher temperature, and then enters the spray for the first-level digestion to improve the spray efficiency. refer to Figure 1 to Figure 6 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com