Modified bentonite load nanometer iron material and preparation method thereof

A technology of bentonite and nano-iron, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of low utilization rate of zero-valent iron, increase the length of packed columns, etc., and achieve strong reduction Ability and adsorption capacity, the effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A modified bentonite loaded nano-iron material and a preparation method thereof. The concrete steps of its preparation method are:

[0034] Step 1. Stir bentonite and 0.05-0.1 mol / L divalent iron salt solution for 30-40 min at a stirring speed of 250-300 r / min to prepare a mixed solution of bentonite and divalent iron salt, in which the iron element The mass ratio to bentonite is 1: (1~2).

[0035] Step 2. Add the reducing agent solution dropwise to the mixed solution of bentonite and ferrous salt under the condition of continuous stirring in step 1,

[0036] The volume ratio of the ferrous salt solution to the reducing agent solution is 1: (0.95-1.05); after the reducing agent solution is added dropwise, continue stirring for 20-40 min to obtain a mixed solution containing bentonite-loaded nano-iron.

[0037] The reducing agent solution is prepared from a sodium hydroxide solution with a mass fraction of 0.2 wt% and a reducing agent, wherein the molar ratio of the re...

Embodiment 2

[0044] A modified bentonite loaded nano-iron material and a preparation method thereof.

[0045] This embodiment is except that ferrous salt is ferrous nitrate and reducing agent is zinc borohydride, all the other are the same as embodiment 1.

[0046] The modified bentonite-loaded nano-iron material prepared by this example is used to remove the heavy metal arsenic (Ⅴ) in the wastewater that exists in anion form at a concentration of 5 mg / L, and the dosage of the modified bentonite-loaded nano-iron material in every liter of wastewater is 1 g, the stirring speed was 250 r / min, room temperature, the pH of the wastewater was 6.0-6.2, and the contact time between the wastewater and the modified bentonite loaded nano-iron was 2 h. After detection and calculation, the removal rate of arsenic (V) in the wastewater is 98.6%.

Embodiment 3

[0048] A modified bentonite loaded nano-iron material and a preparation method thereof. The concrete steps of its preparation method are:

[0049] Step 1. Stir bentonite and 0.1-0.3mol / L ferrous salt solution for 30-40 min at a stirring speed of 250-300 r / min to prepare a mixed solution of bentonite and ferrous salt, in which the iron element The mass ratio to bentonite is 1: (1~2).

[0050] Step 2. Add the reducing agent solution dropwise to the mixed solution of bentonite and ferrous salt under the condition of continuous stirring in step 1,

[0051] The volume ratio of the ferrous salt solution to the reducing agent solution is 1: (0.95-1.05); after the reducing agent solution is added dropwise, continue stirring for 20-40 min to obtain a mixed solution containing bentonite-loaded nano-iron.

[0052] The reducing agent solution is prepared from a sodium hydroxide solution with a mass fraction of 0.2 wt% and a reducing agent, wherein the molar ratio of the reducing agent t...

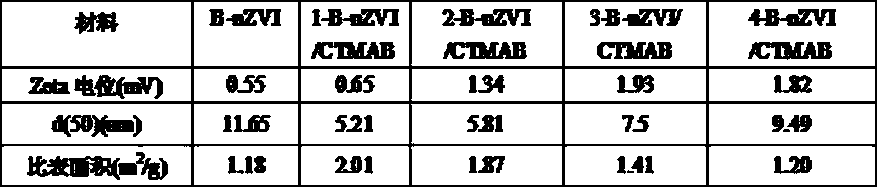

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com