Carboxylation graphene oxide/polyvinylidene fluoride compiste ultrafiltration membrane and preparation method thereof

A technology of polyvinylidene fluoride and carboxylation, which is applied in the field of modified graphene oxide composite membrane and its preparation, can solve the problems of poor hydrophilicity and mechanical properties, and achieve the improvement of hydrophilicity, the reduction of membrane surface contact angle, the The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Concrete preparation process is as follows:

[0030] Dilute the graphene oxide prepared by the Hummers method to 2mg / ml with water, and ultrasonically strip it for 2h to obtain an aqueous solution of graphene oxide, and then add 1.2g of sodium hydroxide and 1.0g of chloroacetic acid to the aqueous solution of graphene oxide per liter. Quantitative calculation, add sodium hydroxide and chloroacetic acid to the aqueous solution of graphene oxide, continue to sonicate for 3 hours, and repeatedly wash the obtained mixed solution with deionized water until the pH of the effluent is 7.0, filter, and the obtained filter cake is stored at 50°C Under drying, carboxylated graphene oxide.

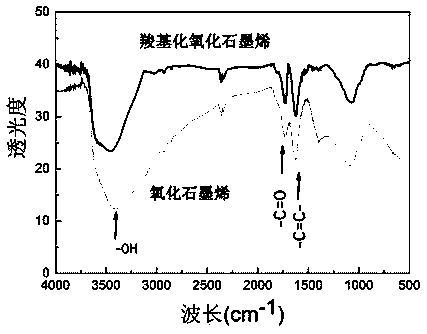

[0031] The infrared spectrum of the above-mentioned graphene oxide used and the obtained carboxylated graphene oxide is measured by the Fourier transform infrared spectroscopic analysis instrument of the Nicolet model of U.S. Minguoli Company, and the results are as follows figure 1 shown, fro...

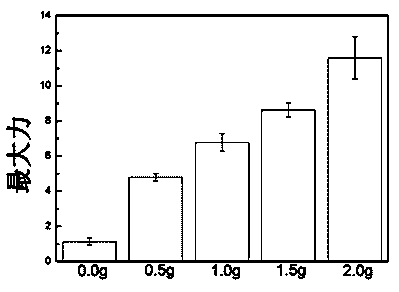

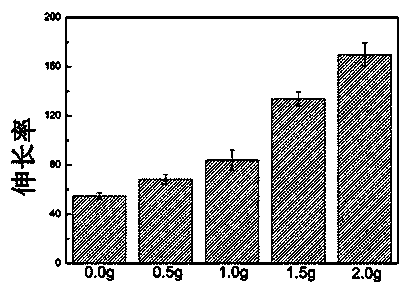

Embodiment 1

[0033] A carboxylated graphene oxide / polyvinylidene fluoride composite ultrafiltration membrane is prepared by a method comprising the following steps:

[0034] Add 18g of polyvinylidene fluoride (that is, the amount of carboxylated graphene oxide added is 0g) to the dual solvent composed of 82g of dimethylacetamide and triethyl phosphate, control the temperature at 60°C, and mechanically stir for 6h to dissolve to obtain a casting solution ;

[0035] Then the resulting casting liquid is naturally cooled to room temperature, and the film is scraped on a glass plate;

[0036] Then immerse the glass plate with the scraped film in a 30°C gel water bath to form a phase separation film, then soak it in deionized water for 4 days, take it out, and dry it naturally in the air to obtain a polyvinylidene fluoride composite ultrafiltration membrane;

[0037] In the dual solvent of dimethylacetamide and triethyl phosphate used, dimethylacetamide and triethyl phosphate are calculated by ma...

Embodiment 2

[0040] A carboxylated graphene oxide / polyvinylidene fluoride composite ultrafiltration membrane is prepared by a method comprising the following steps:

[0041] Add 0.5 g of carboxylated graphene oxide into a dual solvent composed of 82 g of dimethylacetamide and triethyl phosphate, and disperse it ultrasonically for 1 h; then add 18 g of polyvinylidene fluoride, control the temperature at 50°C, and dissolve it with mechanical stirring for 7 h to obtain a casting Membrane fluid;

[0042] Then the resulting casting liquid is naturally cooled to room temperature, and the film is scraped on a glass plate;

[0043] Then, the glass plate with scratch film was immersed in a gel water bath at 28°C to form a phase-separated film, then soaked in deionized water for 5 days, then taken out, and dried naturally in the air to obtain a carboxylated graphene oxide / polyvinylidene fluoride composite supernatant. membrane;

[0044] In the dual solvent of dimethylacetamide and triethyl phospha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com