Thermo-sensitive poly N-isopropylacrylamide/polyurethane medicine-loading electro-spun fibrous membrane and preparation method thereof

A technology of isopropyl acrylamide and electrospun fibers is applied in spinning solution preparation, fiber treatment, pharmaceutical formulations, etc., and can solve the problems of polyurethane drug-loaded electrospun fiber membranes that do not have temperature sensitivity and poor mechanical properties, etc. Achieve the effect of easy operation, high drug loading, and reduced diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

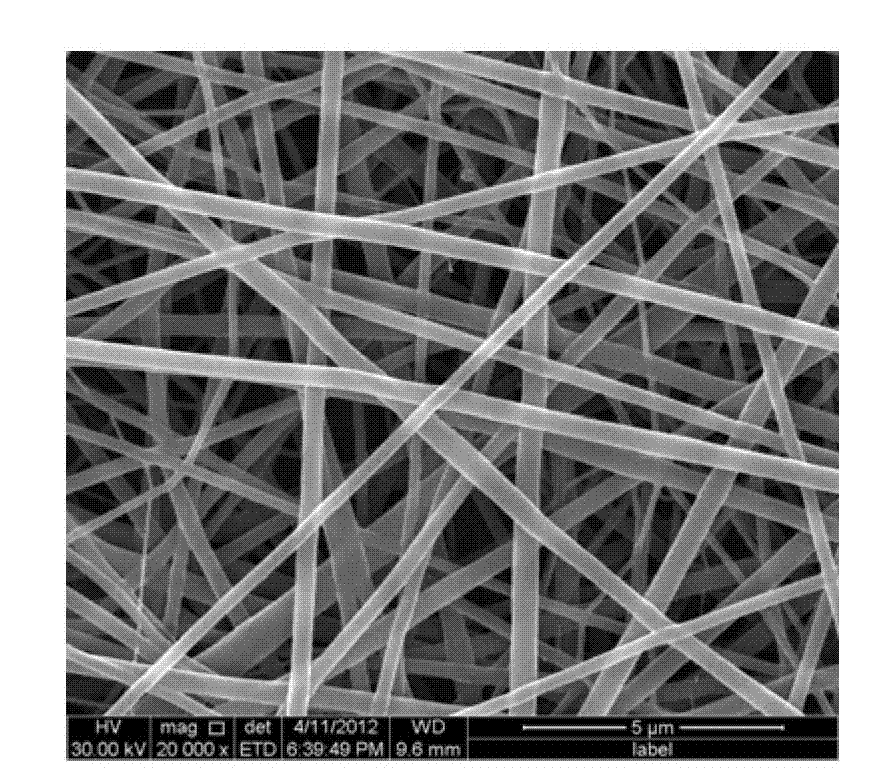

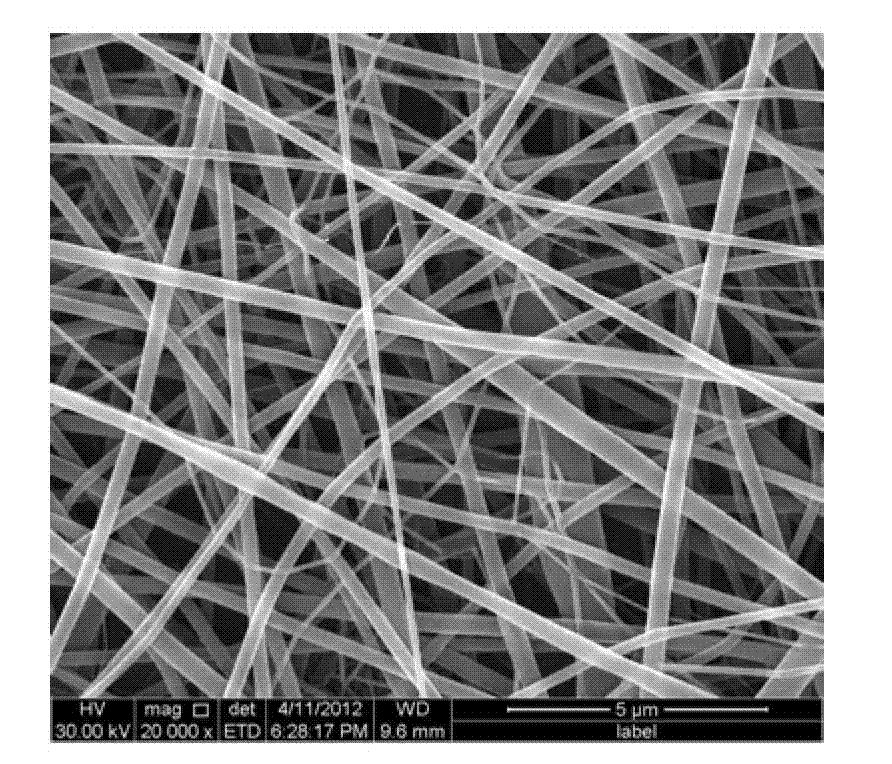

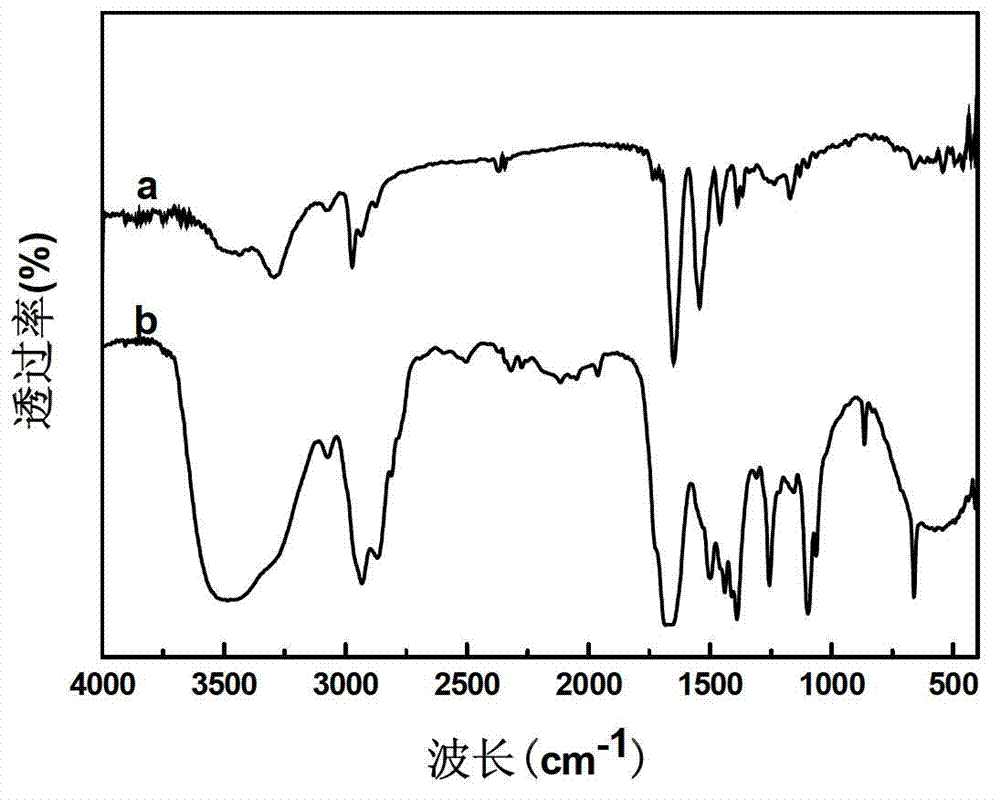

[0010] Embodiment 1: This embodiment is a temperature-sensitive poly N-isopropylacrylamide / polyurethane drug-loaded electrospun fiber membrane made of polyN-isopropylacrylamide, polyurethane, N,N-dimethylformaldehyde It is prepared from amide and medicine; the mass ratio of the poly-N-isopropylacrylamide to the polyurethane is (1~5):1; the total mass of the poly-N-isopropylacrylamide and the polyurethane to N , the mass ratio of N-dimethylformamide is (10 ~ 15): 100; the mass ratio of the mass of the drug to the total mass of polyN-isopropylacrylamide and polyurethane is (5 ~ 50): 100, The medicine mentioned therein is the medicine which can be dissolved in N,N-dimethylformamide.

[0011] The temperature-sensitive poly-N-isopropylacrylamide / polyurethane drug-loaded electrospun fiber membrane described in this embodiment reduces the drug diffusion rate, prolongs the release time, and can maintain the effect of the drug without frequent administration. At the same time, the phe...

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the drug is nifedipine, paclitaxel or daunorubicin. Others are the same as the first embodiment.

specific Embodiment approach 3

[0016] Specific embodiment three: This embodiment is a method for preparing a temperature-sensitive poly-N-isopropylacrylamide / polyurethane drug-loaded electrospun fiber membrane, which is specifically completed according to the following steps:

[0017]1. Configure the electrospinning solution: ① Dissolve poly-N-isopropylacrylamide in N,N-dimethylformamide, dissolve and mix completely to obtain poly-N-isopropylacrylamide with a mass fraction of 10%~14%. Propylacrylamide / N,N-dimethylformamide solution; ②Dissolve polyurethane in N,N-dimethylformamide, completely dissolve and mix to obtain polyurethane / N , N-dimethylformamide solution; ③ Under the condition of magnetic stirring at a stirring speed of 60r / min~300r / min, the mass fraction of 10%~14% polyN-isopropylacrylamide / N,N- The dimethylformamide solution and the polyurethane / N,N-dimethylformamide solution with a mass fraction of 10%~15% are mixed together, and continue to be stirred under the condition of magnetic stirring at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com