Preparation method for high-slump-retention polycarboxylate water reducer

A technology of water reducer and polycarboxylate, which is applied in the field of preparation of high slump polycarboxylate water reducer, can solve the problems of fresh concrete loss that cannot be poured normally, excessive slump loss, waste of manpower and material resources, etc. Achieve the effect of increasing steric hindrance effect, easy control of conditions and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

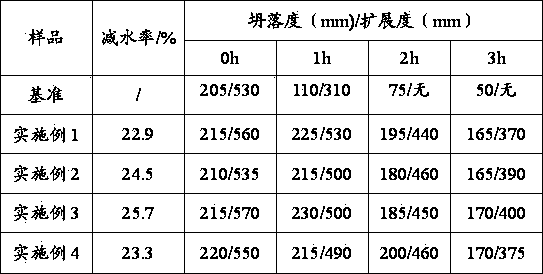

Examples

Embodiment 1

[0023] (1) Preparation of esterification monomer: In parts by mass, 70 parts of methoxypolyethylene glycol monomethyl ether with a molecular weight of 600 and 30 parts of methoxypolyethylene glycol monomethyl ether with a molecular weight of 3000, 33 Parts of methacrylic acid, 2 parts of concentrated sulfuric acid and 0.5 parts of mixed polymerization inhibitor were added to reactor A equipped with a condensing device, and under the protection of nitrogen, they were reacted at a constant temperature of 105 °C for 5 hours, and then 14 parts were added at one time. 2 parts of allyl alcohol, continue to esterify for 2 hours under this condition, after the reaction is completed, add 16.4 parts of water after cooling down to 80°C, and obtain the methoxypolyethylene glycol monomer containing crosslinking monomer allyl methacrylate. Methyl ether methacrylate esterified macromonomer MP; wherein: the mixed polymerization inhibitor is calculated as hydroquinone:phenothiazine=3:1 in parts...

Embodiment 2

[0027] (1) Preparation of esterification monomer: in parts by mass, 50 parts of methoxypolyethylene glycol monomethyl ether with a molecular weight of 1200 and 50 parts of methoxypolyethylene glycol monomethyl ether with a molecular weight of 2200, 33 Parts of methacrylic acid, 5 parts of p-toluenesulfonic acid and 1 part of mixed polymerization inhibitor were added to reactor A equipped with a condensing device, and under the protection of nitrogen, they were reacted at a constant temperature of 130°C for 6 hours, and then Add 11 parts of allyl alcohol, continue the esterification for 2 hours under this condition, and after the reaction is completed, add 16.1 parts of water after cooling down to 80°C to obtain the methoxy polyethylene glycol containing cross-linking monomer allyl methacrylate. Alcohol monomethyl ether methacrylate esterified macromonomer MP;

[0028] (2) Copolymerization reaction: in parts by mass, put 3 parts of sodium styrene sulfonate, 1.8 parts of hydroge...

Embodiment 3

[0031] (1) Preparation of esterification monomer: in parts by mass, 30 parts of methoxypolyethylene glycol monomethyl ether with a molecular weight of 600 and 70 parts of methoxypolyethylene glycol monomethyl ether with a molecular weight of 2200, 31 Parts of methacrylic acid, 3.5 parts of p-toluenesulfonic acid and 0.75 parts of mixed polymerization inhibitor were added to reactor A equipped with a condensing device, and under the protection of nitrogen, they were reacted at a constant temperature of 115°C for 5.5 hours, and then Add 11.5 parts by mass of allyl alcohol, continue the esterification for 2 hours under this condition, and after the reaction is completed, add 15.9 parts of water after cooling down to 80°C to obtain the methoxy Polyethylene glycol monomethyl ether methacrylated macromonomer MP;

[0032](2) Copolymerization reaction: according to mass, put 1.5 parts of sodium methacrylate, 2 parts of hydrogen peroxide and 60 parts of water in reactor B; pump 100 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com