Preparation method for cerium oxide/graphene oxide nanocomposite

A nanocomposite material and graphene technology are applied in the field of preparing cerium oxide/graphene oxide nanocomposite materials, which can solve the problems of uneven dispersion of metal nanoparticles, long reaction time and high requirements, and achieve rapid preparation, short reaction time, Equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

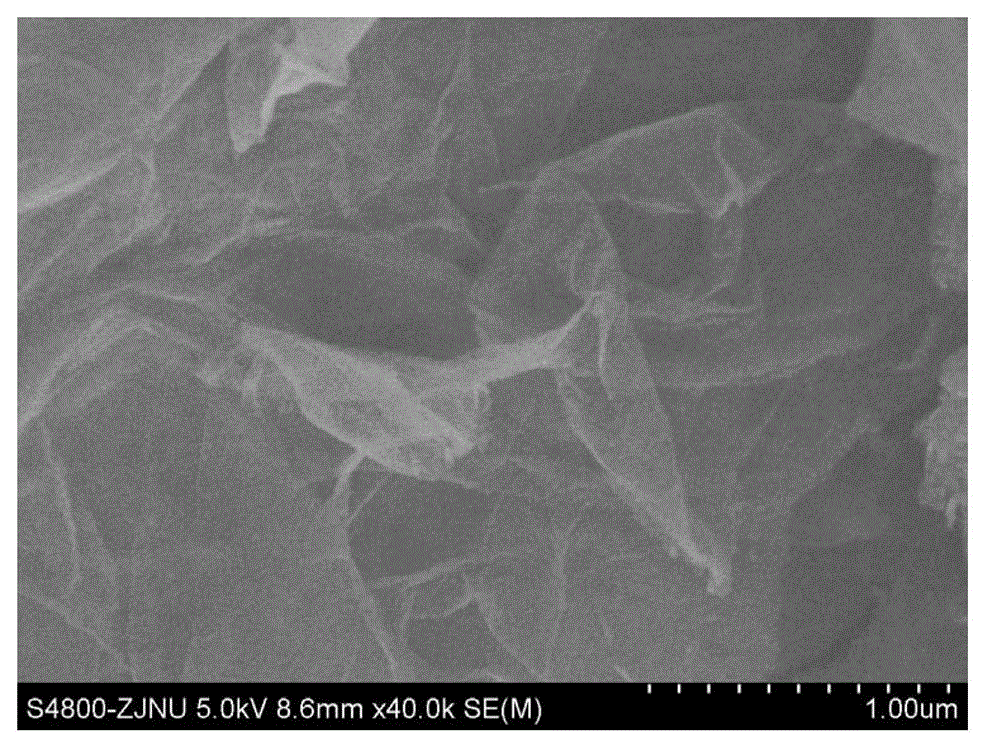

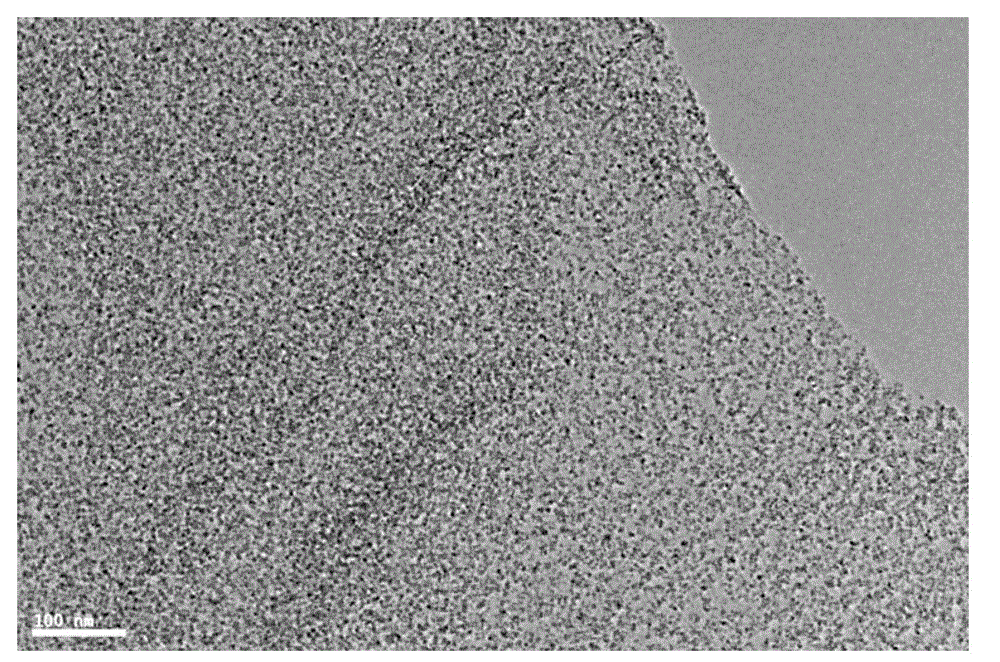

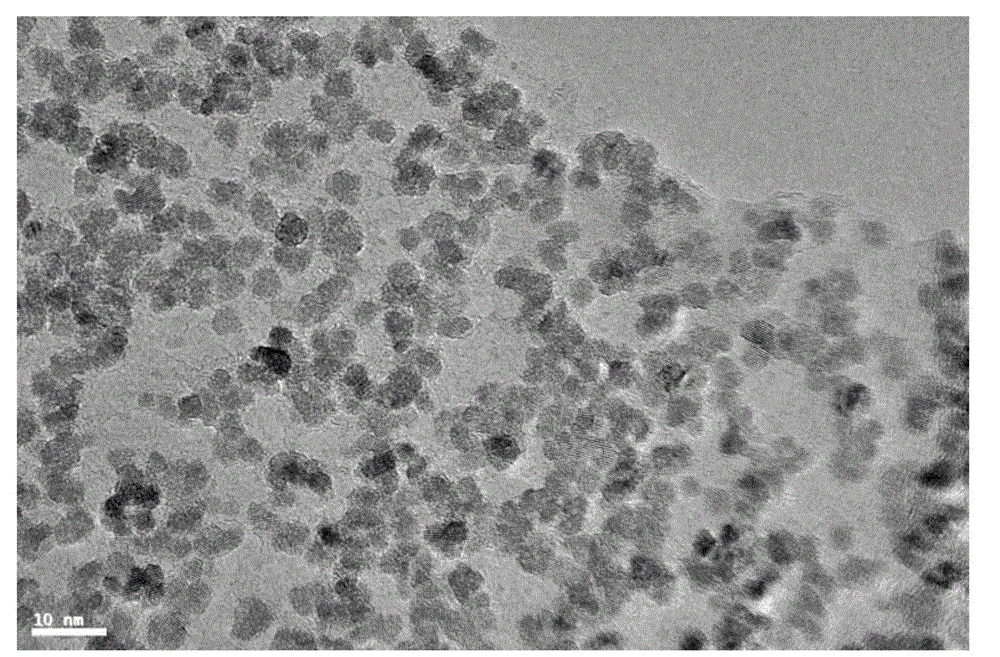

Image

Examples

Embodiment 1

[0040] A kind of preparation method of cerium oxide / graphene oxide nano composite material, the raw material of preparation cerium oxide / graphene oxide nano composite material adopts cerium nitrate, sodium acetate, urea and graphite oxide, and its cerium oxide / graphene oxide nano composite material The preparation method comprises the following steps:

[0041](1) Weigh 0.15g of cerium nitrate, 5.0g of sodium acetate, 0.3g of urea, 0.021g of graphite oxide, and 30g of water;

[0042] (2) Add graphite oxide and water into a round bottom flask, and ultrasonically make graphite oxide form a suspension in water;

[0043] (3) Put cerium nitrate, sodium acetate and urea in a round bottom flask and dissolve them in water;

[0044] (4) Put the round bottom flask into a microwave reactor with a reflux device, turn on the reactor, control the power of the microwave reactor to 500W, and react for 15 minutes to obtain a black precipitate, which is cerium oxide / graphene oxide nanocomposite...

Embodiment 2

[0046] A kind of preparation method of cerium oxide / graphene oxide nanocomposite material, the raw material of preparation cerium oxide / graphene oxide nanocomposite material adopts cerous chloride, sodium acetate, urea and graphite oxide, its cerium oxide / graphene oxide nanocomposite The preparation method of material comprises the following steps:

[0047] (1) Weigh 0.3g of cerous chloride, 10.0g of sodium acetate, 0.6g of urea, 0.042g of graphite oxide, and 60g of water;

[0048] (2) Add graphite oxide and water into a round bottom flask, and ultrasonically make graphite oxide form a suspension in water;

[0049] (3) Put cerous chloride, sodium acetate and urea in a round bottom flask to dissolve them in water;

[0050] (4) Put the round bottom flask into a microwave reactor with a reflux device, turn on the reactor, control the power of the microwave reactor to 500W, and react for 15 minutes to obtain a black precipitate, which is cerium oxide / graphene oxide nanocomposite ...

Embodiment 3

[0052] A kind of preparation method of cerium oxide / graphene oxide nanocomposite material, the raw material of preparation cerium oxide / graphene oxide nanocomposite material adopts cerium sulfate, sodium acetate, urea and graphite oxide, and its cerium oxide / graphene oxide nanocomposite material The preparation method comprises the following steps:

[0053] (1) Weigh 0.15g of ceric sulfate, 5.0g of sodium acetate, 0.3g of urea, 0.021g of graphite oxide, and 30g of water;

[0054] (2) Add graphite oxide and water into a round bottom flask, and ultrasonically make graphite oxide form a suspension in water;

[0055] (3) Put ceric sulfate, sodium acetate and urea in a round bottom flask to dissolve them in water;

[0056] (4) Put the round bottom flask into a microwave reactor with a reflux device, turn on the reactor, control the power of the microwave reactor to 500W, and react for 15 minutes to obtain a black precipitate, which is cerium oxide / graphene oxide nanocomposite Mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com