Highly-adaptive ultra-slow-release type polycarboxylate slump retaining admixture and preparation method thereof

An ultra-sustained release and adaptable technology, applied in the field of building materials, can solve the problems of not being able to fully meet the market demand, the improvement of the slump retention effect is not obvious, and the slump retention performance is insufficient. The effect of good collapse ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

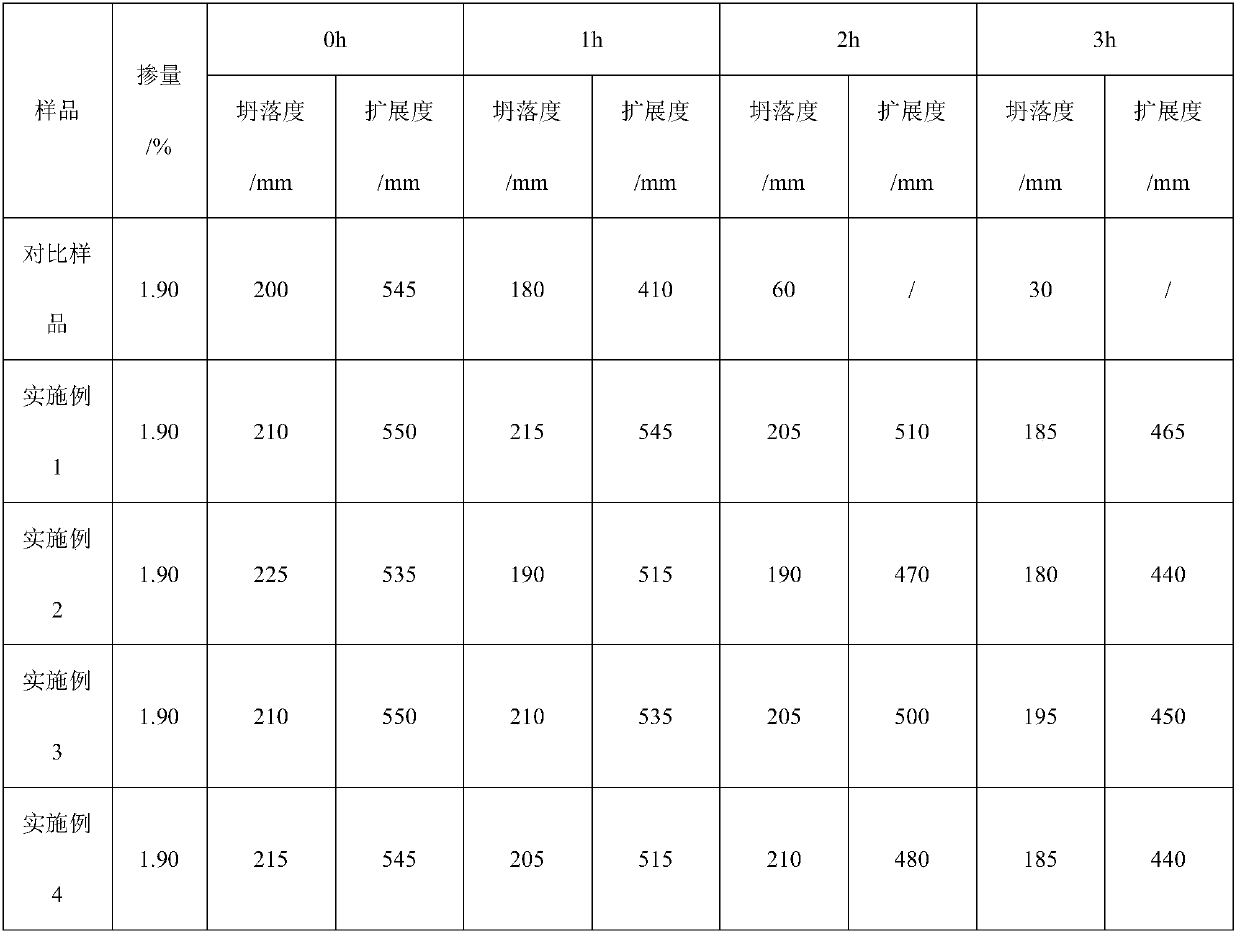

Embodiment 1

[0032] (1) Preparation of unsaturated esterified small monomers:

[0033] Under normal pressure, 41 parts of methacrylic acid, 71 parts of propionic acid, 130 parts of 3-bis(2-hydroxyethyl)amino-2-hydroxypropanesulfonic acid (DIPSO) were added to the reactor, and 0.25 1 part of titanium trichloride, 0.13 part of benzyl tributyl ammonium chloride and 13 parts of petroleum ether, carry out esterification reaction, the esterification reaction temperature is 100 ℃, and the reaction time is 3 hours, and after the reaction is completed, it is cooled to room temperature, that is Obtain unsaturated esterified small monomers.

[0034] (2) Copolymerization reaction:

[0035] At room temperature, in parts by weight, 1 part of diethyl vinyl phosphate, 3 parts of 2-[2-(furan-2-yl) vinyl]-4,6-bis(trichloromethyl)-1, 3,5 triazine and appropriate amount of water were placed in a four-necked flask and stirred.

[0036] Mix 100 parts of 4-hydroxybutyl vinyl ether polyoxyethylene ether with a...

Embodiment 2

[0041] (1) Preparation of unsaturated esterified small monomers:

[0042] Under normal pressure, 60 parts of methacrylic acid, 162 parts of butyric acid, 130 parts of 3-bis(2-hydroxyethyl)amino-2-hydroxypropanesulfonic acid (DIPSO) were added to the reactor, and 0.55 1 part of sodium p-toluenesulfonate, 0.45 part of tris(N-nitroso-N-phenylhydroxylamine) aluminum and 18 parts of cyclohexane, carry out esterification reaction, the esterification reaction temperature is 110 ℃, and the reaction time is 4 hours , After the reaction is completed, the temperature is lowered to room temperature, and the unsaturated esterified small monomer is obtained.

[0043] (2) Copolymerization reaction:

[0044]At room temperature, in parts by weight, 2 parts of diethyl vinyl phosphate, 2 parts of 2-(3,4-dimethoxy)-4,6-bis(trichloromethyl)-1,3,5 -Triazine and appropriate amount of water are placed in a four-necked flask and stirred.

[0045] Mix 100 parts of 4-hydroxybutyl vinyl ether polyoxye...

Embodiment 3

[0050] (1) Preparation of unsaturated esterified small monomers:

[0051] Under normal pressure, 90 parts of methacrylic acid, 85 parts of butyric acid, 130 parts of 3-bis(2-hydroxyethyl)amino-2-hydroxypropanesulfonic acid (DIPSO) were added to the reactor, and 0.6 1 part of titanium trichloride, 0.35 part of benzyltributylammonium chloride and 40 parts of sherwood oil, carry out esterification reaction, the esterification reaction temperature is 120 ℃, and the reaction time is 5 hours, after the reaction finishes, it is down to room temperature, namely Obtain unsaturated esterified small monomers.

[0052] (2) Copolymerization reaction:

[0053] At room temperature, in parts by weight, 3 parts of diethyl vinyl phosphate, 5 parts of diphenyliodonium trifluoromethanesulfonate and appropriate amount of water were placed in a four-necked flask and stirred.

[0054] Mix 100 parts of 4-hydroxybutyl vinyl ether polyoxyethylene ether with a weight average molecular weight of 3000 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com