Concrete cement-reducing agent and preparation method thereof

A technology of glue reducing agent and concrete, applied in the field of concrete additives, can solve the problems of poor comprehensive performance of the glue reducing agent, unstable performance of admixtures, poor component compatibility, etc. The effect of improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

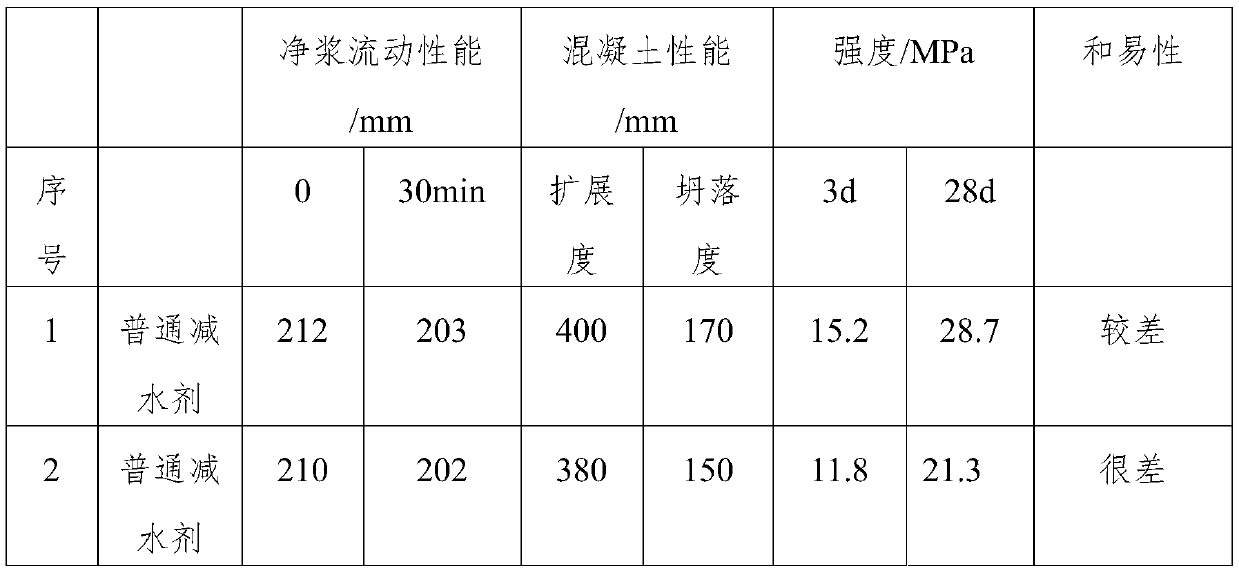

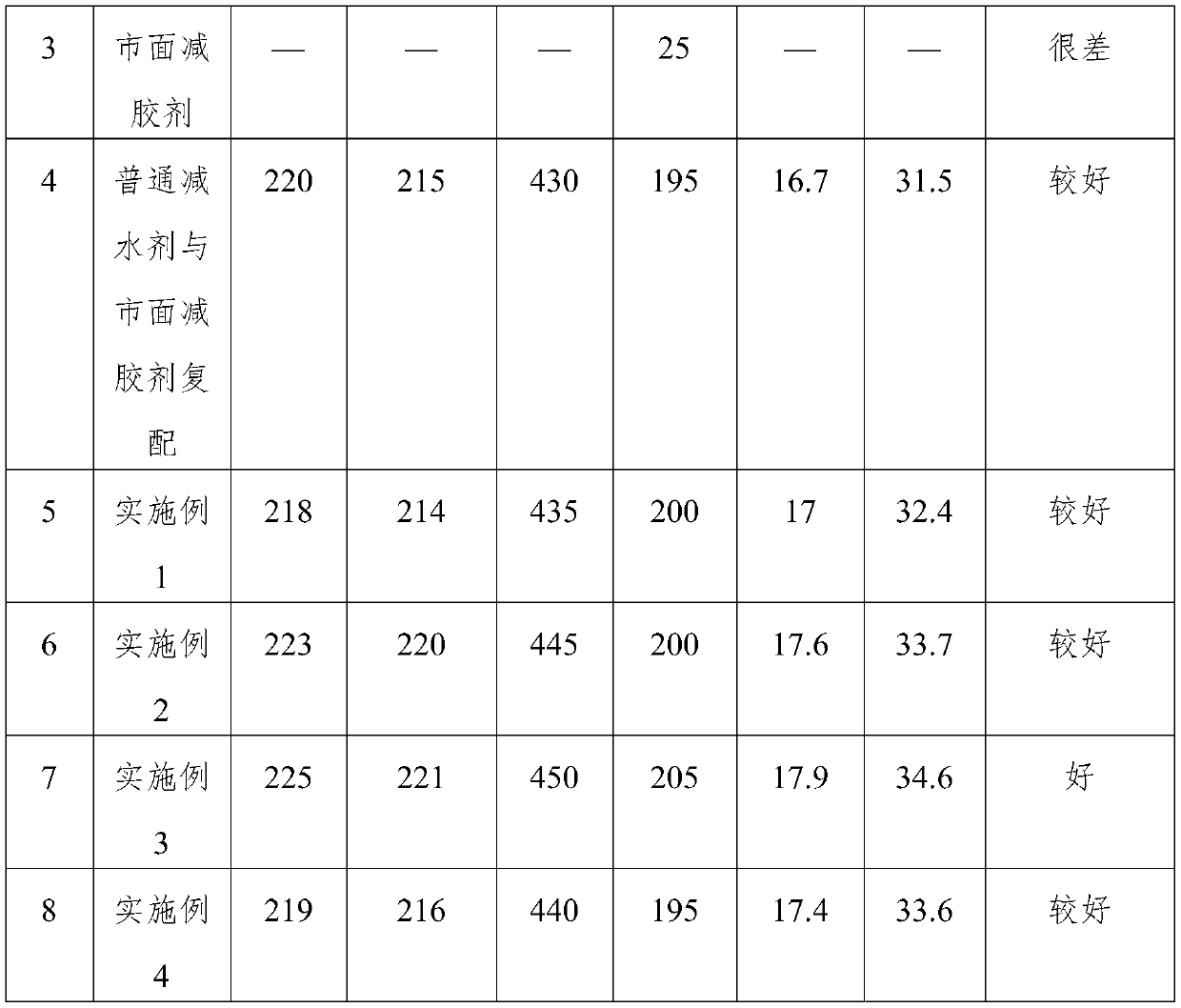

Examples

Embodiment 1

[0045] The present embodiment provides a kind of preparation method of concrete reducer, and it comprises the steps:

[0046] Weigh an appropriate amount of OXST-807 polyether monomer, modified ethylene glycol amine and pure water into a four-necked flask, and stir to dissolve it. OXST-807 polyether monomer accounted for 32% of the total mass of the adhesive reducer, and modified ethylene glycol amine accounted for 1.0% of the total mass of the adhesive reducer. After the monomers were completely dissolved, the oxidant ammonium persulfate was added. Hydrogen peroxide (content 30%) accounts for 0.4% of the total mass of the glue reducer, and the first solution and the second solution are added dropwise after 5 minutes.

[0047] The first solution is made up of mercaptopropionic acid, (vitamin C) VC and pure water, which are completely dissolved and stirred evenly, wherein mercaptopropionic acid accounts for 0.1% of the total mass of the adhesive reducer, and VC accounts for 0.1...

Embodiment 2

[0050] The present embodiment provides a kind of preparation method of concrete reducer, and it comprises the steps:

[0051] Weigh an appropriate amount of OXST-807 polyether monomer, modified ethylene glycol amine and pure water into a four-necked flask, and stir to dissolve it. OXST-807 polyether monomer accounts for 34% of the total weight of the glue reducer, and modified diethanolamine is 0.5%. After the monomer is completely dissolved, the oxidant ammonium persulfate is added. Ammonium persulfate accounts for 0.1% of the total mass of the glue reducer, and the first solution and the second solution are added dropwise after 5 minutes.

[0052] The first solution is made up of mercaptoethanol, D-isoascorbic acid and pure water, which are completely dissolved and stirred evenly, wherein mercaptoethanol accounts for 0.1% of the total mass of the adhesive reducer, and D-isoascorbic acid accounts for 0.08% of the total mass of the adhesive reducer. %.

[0053] The second so...

Embodiment 3

[0056] The present embodiment provides a kind of preparation method of concrete reducer, and it comprises the steps:

[0057] Weigh an appropriate amount of OXST-807 polyether monomer, modified ethylene glycol amine and pure water into a four-necked flask, and stir to dissolve it. OXST-807 polyether monomer accounts for 33% of the total weight of the glue reducer, and modified diethanolamine is 1.7%. After the monomer is completely dissolved, the oxidant potassium persulfate is added. Potassium persulfate accounts for 0.15% of the total mass of the glue reducer, and the first solution and the second solution are added dropwise after 5 minutes.

[0058] The first solution is made up of thioglycolic acid, sodium hypophosphite and pure water, which are completely dissolved and stirred evenly, wherein thioglycolic acid accounts for 0.07% of the total mass of the adhesive reducer, and sodium hypophosphite accounts for 0.15% of the total mass of the adhesive reducer. %.

[0059] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com