Reduction type ether polycarboxylic acid water reducer and preparation method thereof

A technology of ether polycarboxylic acid and water reducing agent, which is applied in the field of concrete admixture, can solve the problems of non-condensing of concrete, high cost of shrinkage reducing agent and expansion agent, so as to prevent shrinkage cracking, ensure workability, and increase steric resistance effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

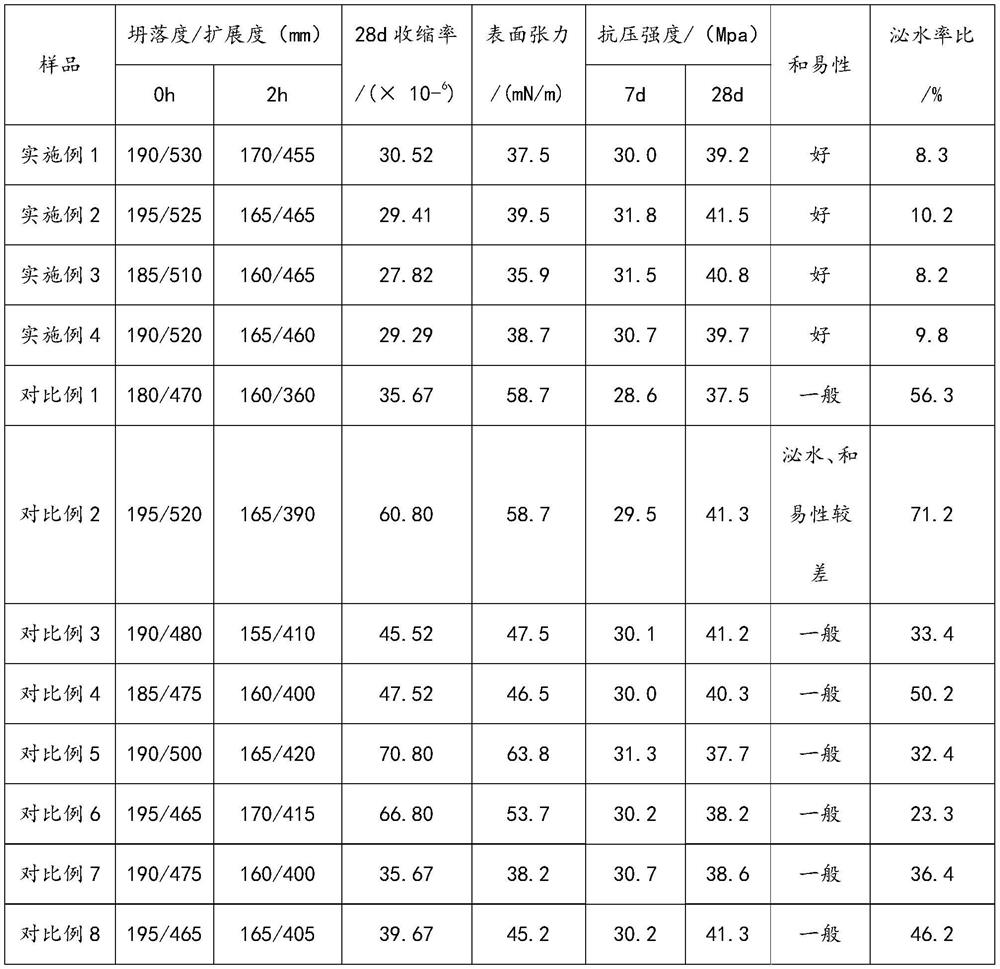

Examples

Embodiment 1

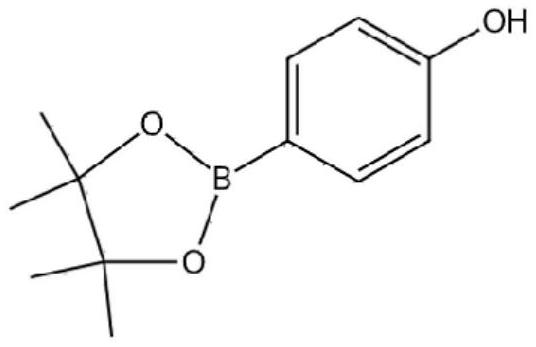

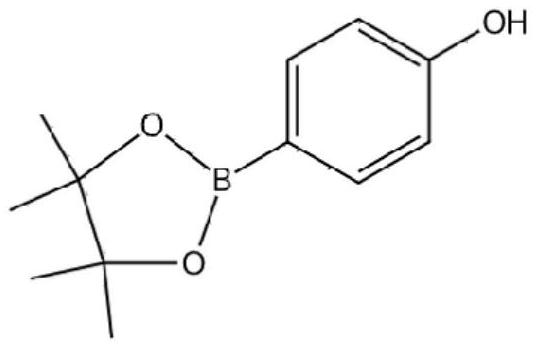

[0037] A1, preparation of esterification product: preparation of esterification product: in parts by weight, add 72 parts of acrylic acid and 100 parts of 4-hydroxyphenylboronic acid pinacaester into the first reaction vessel for mixing, and under nitrogen protection conditions, add 3.6 parts of para Toluenesulfonic acid, 2.8 parts of hydroquinone, and adjust the reaction temperature to 120°C, and react for 5 hours to obtain the esterified product;

[0038]A2, copolymerization reaction: by weight, first 5 parts of the esterification product prepared by A1, 100 parts of 4-hydroxybutyl vinyl ether polyoxyethylene ether with a molecular weight of 4000, 2 parts of trans-2-[4- (Trifluoromethyl)phenyl]vinylboronic acid, 0.7 part of polyoxyethylene sorbitan tetraoleate and 118 parts of water are added into the second reaction vessel and stirred evenly, and 0.8 part of ammonium persulfate is mixed with 20 parts of water evenly In the first dropping device; 3 parts of ferrous sulfate, ...

Embodiment 2

[0041] B1, preparation of esterification product: by weight, 156.3 parts of methacrylic acid, 100 parts of 4-hydroxyphenylboronic acid pinacidate are added in the first reaction vessel and mixed, under the condition of nitrogen protection, 2 parts of concentrated sulfuric acid are added, 7.7 part of diphenylamine, and adjust the reaction temperature to 135°C, and react for 5 hours to obtain the esterified product;

[0042] B2, copolymerization reaction: by weight, earlier the esterification product that 7 parts of B1 make, the ethylene glycol monovinyl polyoxypropylene ether of 100 parts of molecular weight 2400, 1.4 parts of trans-2-[4-(three Fluoromethyl)phenyl]vinylboronic acid, 1.2 parts of polyoxyethylene sorbitan tetraoleate and 131 parts of water are added to the second reaction vessel and stirred evenly, and 1.5 parts of sodium persulfate and 20 parts of water are mixed evenly in the second reaction vessel In one dropping device; 1 part of sodium hypophosphite, 2 parts...

Embodiment 3

[0045] C1. Preparation of esterification product: In parts by weight, add 66.4 parts of methacrylic acid and 100 parts of 4-hydroxyphenylboronic acid pinacidate into the first reaction vessel for mixing, and add 2.3 parts of p-toluenesulfonic acid under the condition of nitrogen protection , 3.5 parts of methyl hydroquinone, and adjust the reaction temperature to 125°C, and react for 4 hours to obtain the esterification product;

[0046] C2, copolymerization reaction: by weight, first the esterification product that 6 parts of C1 make, 100 parts of methallyl monomethyl ether polyoxyethylene ether of molecular weight 3000, 0.8 part of trans-2-[4- (Trifluoromethyl) phenyl] vinyl boronic acid, 2 parts of polyoxyethylene sorbitan tetraoleate and 129 parts of water, add in the second reaction vessel and stir evenly, 2.8 parts of tert-butyl hydroperoxide and 20 parts Mix water in the first dropping device; mix 2.6 parts of ascorbic acid, 0.5 parts of potassium hypophosphite and 20 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com