Solid flaky polycarboxylate slump retaining agent prepared by surfactant-free emulsion polymerization and method

A soap-free emulsion polymerization and polycarboxylic acid technology, which is applied in the field of building materials and polycarboxylic acid slump-retaining agents, can solve the problems that slump-retaining agents cannot slow down cement hydration for a long time, are not suitable for high temperature and dry environments, and avoid Incomplete reaction, good slump retention, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

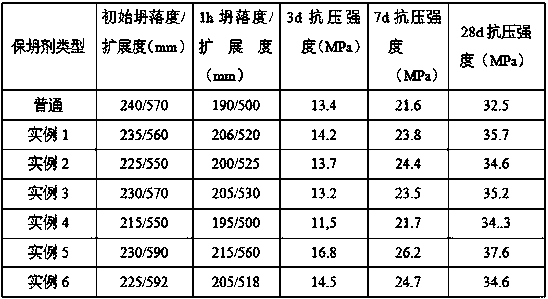

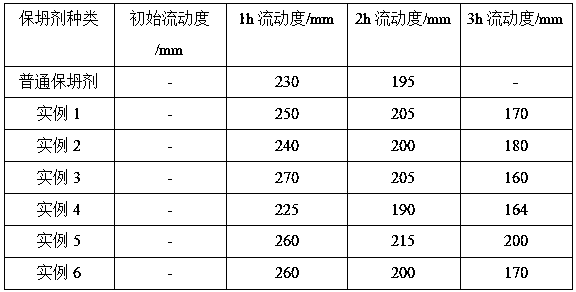

Examples

example 1

[0034] A kind of solid flaky polycarboxylic acid slump-retaining agent prepared by soap-free emulsion polymerization method is prepared by comprising the following components by weight, the total mass of raw materials is 1000 parts, and the parts by weight of each component are:

[0035] 2-propylheptyl acrylate: 20 parts; tetrabutylphosphine acetate: 16 parts; the composition of lauryl peroxide and dicyclohexyl peroxydicarbonate with a mass ratio of 1:1: 0.56 parts; times Sodium phosphite: 0.44 parts; Methallyl polyoxyethylene ether: 790 parts; Acrylic acid: 66 parts; Sodium methacrylate: 19 parts; 2,2,2-trifluoroethyl methacrylate: 63 parts sodium hypophosphite: 2.9 parts; azobisisoheptanonitrile: 4.4 parts; tert-butyl peroxyvaleric acid: 3.8 parts; aliphatic mercaptan: 4.1 parts;

[0036] A method for preparing solid sheet-like polycarboxylic acid slump-retaining agent with soap-free emulsion polymerization, described method is carried out as follows:

[0037] 1. Preparatio...

example 2

[0042] A kind of solid flaky polycarboxylic acid slump-retaining agent prepared by soap-free emulsion polymerization method is prepared by comprising the following components by weight, the total mass of raw materials is 1000 parts, and the parts by weight of each component are:

[0043] 2-methacryloyloxyethyl ester: 25 parts; the composition of tetraethylammonium nitrate and tetrapropylammonium chloride with a mass ratio of 1:1: 12 parts; dicyclohexyl peroxydicarbonate: 0.68 parts ; Sodium methacryl sulfonate: 0.52 parts; Allyl polyoxyethylene ether: 804 parts; Maleic anhydride: 40 parts; The composition of sodium vinyl sulfonate and sodium propylene sulfonate with a mass ratio of 1:1 : 23 parts; the composition of trifluoroethyl acrylate and perfluorobutyl ethyl acrylate with a mass ratio of 1:1: 70 parts; sodium formate: 3.2 parts; azobisisoheptanonitrile with a mass ratio of 2:1 Composition with diisopropyl peroxydicarbonate: 4.1 parts; tert-butyl peroxy-tert-valerate: 4.2...

example 3

[0050] A kind of solid flaky polycarboxylic acid slump-retaining agent prepared by soap-free emulsion polymerization method is prepared by comprising the following components by weight, the total mass of raw materials is 1000 parts, and the parts by weight of each component are:

[0051] Composition of 2-methacryloyloxyethyl ester and methacryloyloxyethyl hexahydrophthalic acid monoester with a mass ratio of 1:1: 24 parts; tetramethylammonium fluoride: 16 parts; Lauroyl oxide: 0.62 parts; Sodium methacrylate: 0.68 parts; Prenol polyoxyethylene ether: 768 parts; Composition of acrylic acid and maleic anhydride with a mass ratio of 1:2: 68 parts; Mass Composition of sodium propenyl sulfonate and sodium styrene sulfonate at a ratio of 2:1: 25 parts; perfluorobutyl ethyl acrylate: 70 parts; sodium polyphosphate: 3.4 parts; azobisisoheptanonitrile: 5.3 parts; the composition of azobisisobutyronitrile and tert-butyl peroxyvaleric acid with a mass ratio of 1:1: 3.6 parts; dithioester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com