Super retarding concrete and application thereof

A concrete and ultra-retarding technology, which is applied in the application field of ultra-retarding concrete in the construction of full-casing drilling rig hole-forming clinch piles, and achieves the effects of good water retention and prolonged setting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

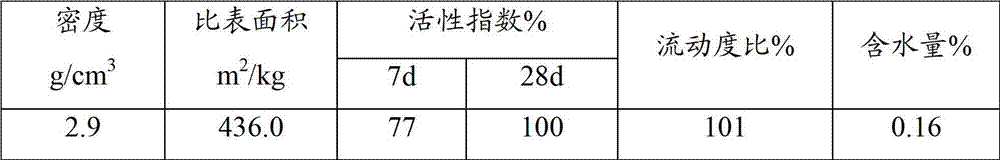

[0022] The preferred embodiments of the present invention are given below to describe the technical solution of the present invention in detail.

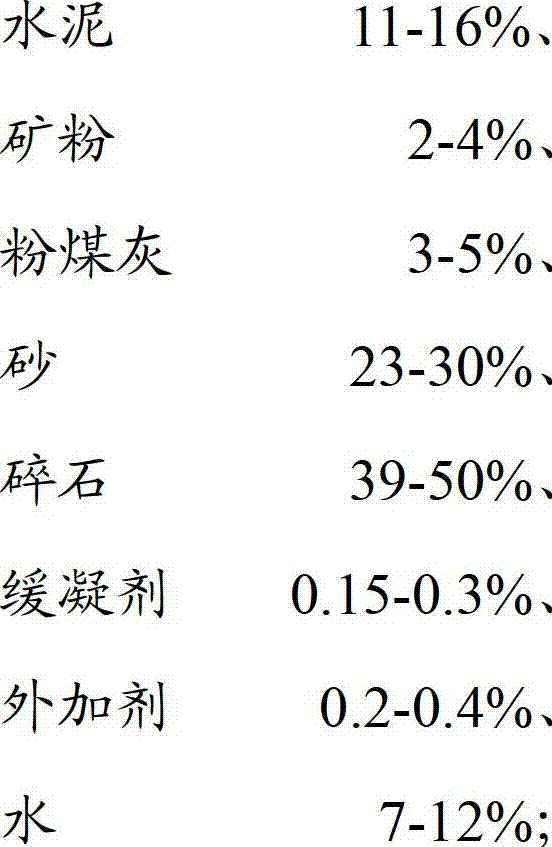

[0023] 1. Selection of raw materials:

[0024] (1) Cement:

[0025] The P.O42.5 cement produced by Shanghai Haibao Cement Factory is used, and its performance meets the standard requirements of GB175-2007. The physical properties of cement are listed in Table 1.

[0026] Table 1 cement physical properties table

[0027]

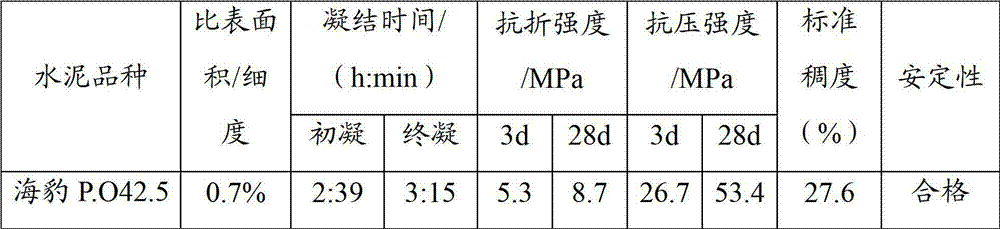

[0028] (2) Mineral powder:

[0029] The S95 slag produced by Baotian New Building Materials Co., Ltd. is used, and it complies with "Granulated Blast Furnace Slag Used in Cement and Concrete" (GB / T18046). The performance indicators are shown in Table 2.

[0030] Table 2 Main properties of slag powder

[0031]

[0032] (3) Sand: sand in Lujiang River

[0033] Lujiang medium sand is used, and its quality meets the standard requirements of JGJ52-2006. The performance indicators are shown in Table 3.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com