Non-dispersible underwater concrete additive, preparation method, and application thereof

A concrete admixture and dispersion technology, which is applied in the field of concrete, can solve problems such as over-mixing, viscosity reduction, and increase in the viscosity of concrete mixtures, so as to avoid strength loss, increase cohesion, and improve work performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

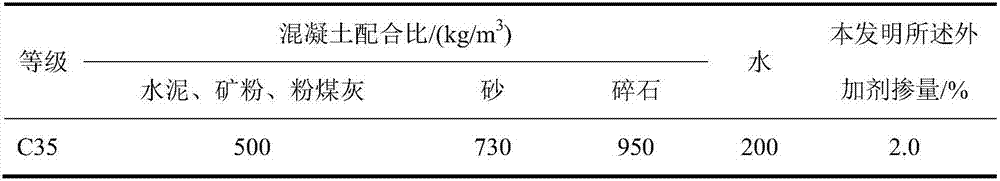

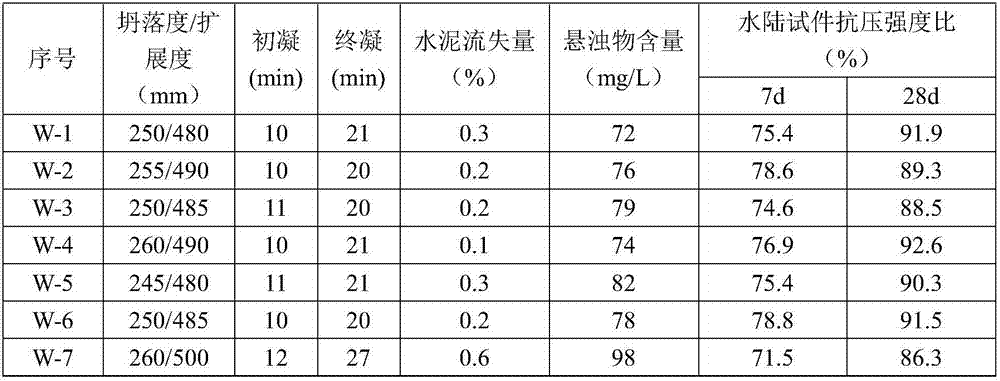

Examples

Embodiment 1

[0032]An underwater non-dispersible concrete admixture, which consists of: modified flocculant solution XN-1 with a mass fraction of about 1%, polycarboxylate water reducer A, polycarboxylate water reducer B, polyether dispersant Foaming agent prevol 544x and air-entraining agent AE-II, the composition is calculated by mass percentage: modified flocculant solution 87%, polycarboxylate water reducer 8%, polycarboxylate water reducer 4%, defoaming 0.6% air-entraining agent and 0.4% air-entraining agent; gradually add the above components into the reaction kettle according to the proportion, and stir evenly to obtain the underwater non-dispersible concrete admixture W-1.

[0033] Wherein, the modified flocculant solution XN-1 is prepared by adding 100 g of deionized water and 15 g of acrylamide Monomer, 0.65g of N,N'-methylenebisacrylamide, stir until the monomer is completely dissolved, and pass nitrogen gas to replace the air in the flask; then heat to 40°C, add 0.1g of ammoniu...

Embodiment 2

[0035] An underwater non-dispersible concrete admixture, which consists of: modified flocculant solution XN-2 with a mass fraction of about 1%, polycarboxylate water reducer A, polycarboxylate water reducer B, polyether dispersant The composition of foam agent prevol 544x and air-entraining agent AE-II is calculated by mass percentage: modified flocculant solution 84%, polycarboxylate water reducer A 10%, polycarboxylate water reducer B 5%, disinfectant 0.3% foaming agent, 0.7% air-entraining agent; gradually add the above components into the reaction kettle according to the proportion, and stir evenly to obtain the underwater non-dispersible concrete admixture W-2.

[0036] Wherein, the modified flocculant solution XN-2 is prepared by adding 100 g of deionized water and 15 g of acrylamide Monomer, 0.3g of N,N'-methylenebisacrylamide, stirred until the monomer is completely dissolved. Introduce nitrogen to replace the air in the flask; heat to 40°C, then add 0.1g of ammonium ...

Embodiment 3

[0038] An underwater non-dispersible concrete admixture, which consists of: modified flocculant solution XN-3 with a mass fraction of about 1%, polycarboxylate water reducer A, polycarboxylate water reducer B, polyether dispersant Foaming agent prevol 544x and air-entraining agent AE-II, the composition is calculated by mass percentage: modified flocculant solution 85%, polycarboxylate water reducer A9%, polycarboxylate water reducer B 5%, disinfectant 0.4% foaming agent, 0.6% air-entraining agent; gradually add the above components into the reaction kettle, and stir evenly to obtain the underwater non-dispersible concrete admixture W-3.

[0039] Wherein, the modified flocculant solution XN-3 is prepared by adding 100 g of deionized water and 15 g of acrylamide Monomer, 0.25g of diacryloylpiperazine, stirred until the monomer is completely dissolved. Introduce nitrogen to replace the air in the flask; heat to 40°C, then add 0.12g of ammonium persulfate and 0.08g of ascorbic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com