Coagulant for concrete depositing in water

A technology of concrete and coagulant, which is applied in the field of improving the setting time of concrete in water, which can solve the problems of complex construction technology, poor concrete strength, and long setting time, and achieve the effect of simple process, maintaining uniformity and increasing setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

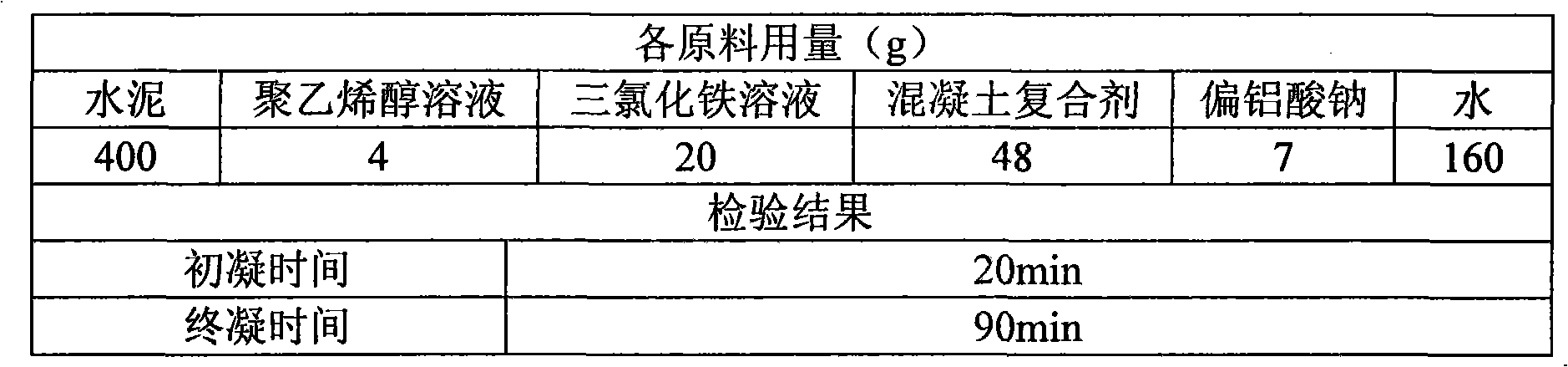

Embodiment 1

[0018] Example 1: Each serving is 1 kg

[0019] A coagulant for pouring concrete in water, consisting of 1% polyvinyl alcohol solution, 2% ferric chloride solution, sodium metaaluminate and concrete compounding agent, based on the weight of 100 kg of cement in concrete, the above The contents of each component are: 0.8 kg of polyvinyl alcohol solution with a concentration of 1%, 1 kg of ferric chloride solution with a concentration of 2%, 1.5 kg of sodium metaaluminate, and 12 kg of concrete compounding agent. It is composed of the following raw materials in weight percentage: 50% of silicon dioxide, 35% of fluorspar, 5.5% of sodium cetylbenzenesulfonate, 8.7% of hydroxycarboxylic acid, and 0.8% of aliphatic hydroxysulfonate high-efficiency water reducer.

[0020] When pouring concrete in water, firstly, according to the amount of cement in the known formula concrete used, and then according to the ratio of the above cement and each component to obtain the corresponding dosage...

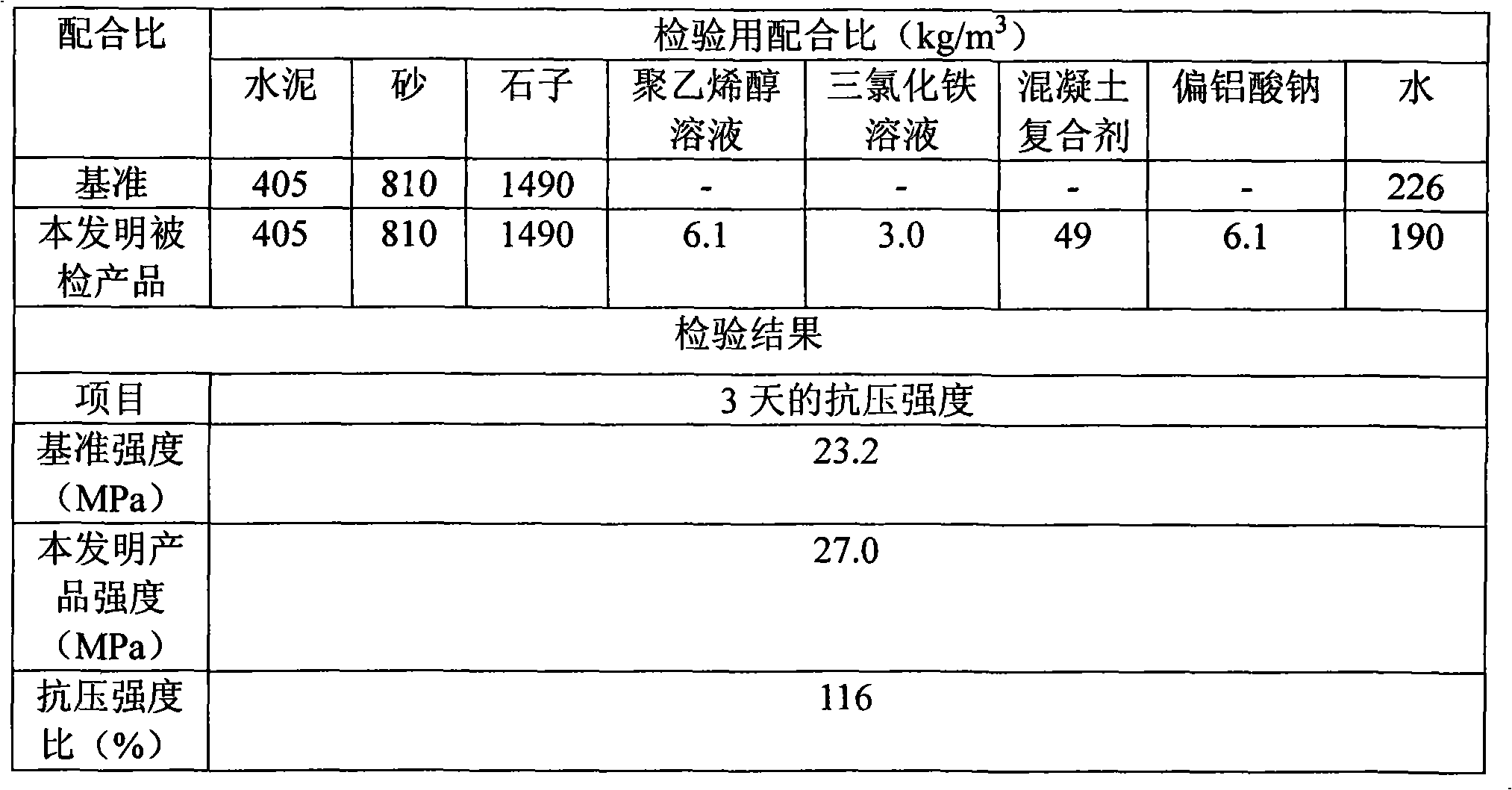

Embodiment 2

[0021] Embodiment 2: every part is 1 ton

[0022] A coagulant for pouring concrete in water, consisting of 1% polyvinyl alcohol solution, 2% ferric chloride solution, sodium metaaluminate and concrete compounding agent, based on the weight of 100 tons of cement in concrete, the above The content of each component is: 2 tons of polyvinyl alcohol solution with a concentration of 1%, 5 tons of ferric chloride solution with a concentration of 2%, 2 tons of sodium metaaluminate, and 12 tons of concrete compounding agent. It is composed of the following raw materials in weight percentage: 49% of silicon dioxide, 40% of fluorspar, 5% of sodium cetylbenzenesulfonate, 5.5% of hydroxycarboxylic acid, and 0.5% of aliphatic hydroxysulfonate high-efficiency water reducer.

[0023] When pouring concrete in water, firstly, according to the amount of cement in the known formula concrete used, and then according to the ratio of the above cement and each component to obtain the corresponding do...

Embodiment 3

[0024] Embodiment 3: every part is 10 tons

[0025] A coagulant for pouring concrete in water, consisting of 1% polyvinyl alcohol solution, 2% ferric chloride solution, sodium metaaluminate and concrete compounding agent, based on the weight of 1000 tons of cement in concrete, the above The content of each component is: 10 tons of polyvinyl alcohol solution with a concentration of 1%, 10 tons of ferric chloride solution with a concentration of 2%, 18 tons of sodium metaaluminate, and 120 tons of concrete compounding agent. It is composed of the following raw materials in weight percentage: 55% of silicon dioxide, 32% of fluorspar, 7.5% of sodium cetylbenzenesulfonate, 4.5% of hydroxycarboxylic acid, and 1% of aliphatic hydroxysulfonate high-efficiency water reducer.

[0026] When pouring concrete in water, firstly, according to the amount of cement in the known formula concrete used, and then according to the ratio of the above cement and each component to obtain the correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com