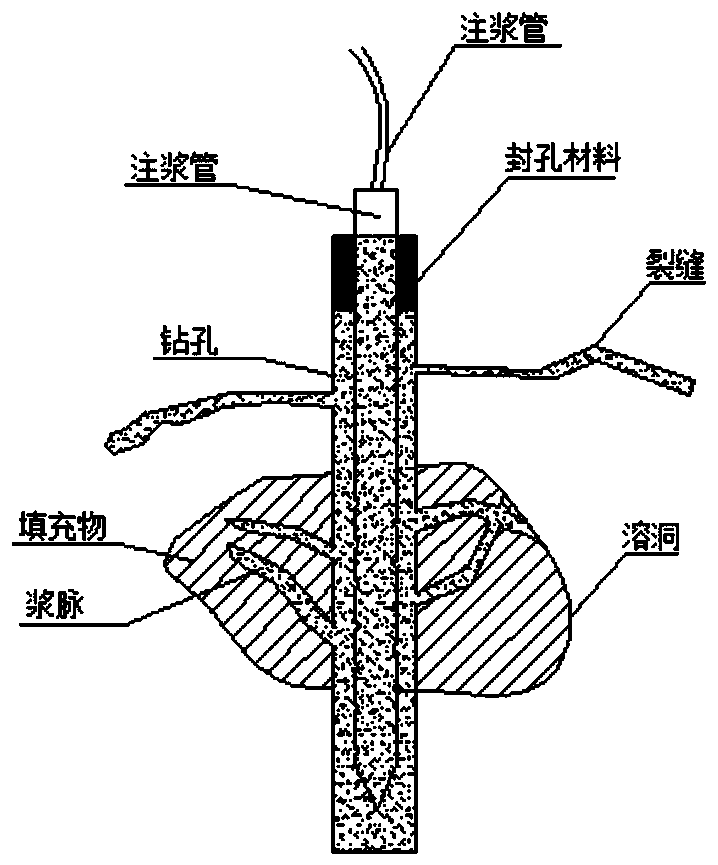

Hole sealing material for karst water inflow and preparation method and hole sealing method thereof

A sealing material and karst technology, which is applied in the field of karst water gushing sealing material and its preparation, can solve the problems of difficult effective sealing of pipe wall gaps, failure of sealing effect, and influence of grouting effect, etc., to achieve water blocking Convenient construction, improved sealing efficiency, and good water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A pore sealing material for karst water inflow of the present invention, comprising the following components by weight:

[0041] Portland cement 80 parts,

[0042] 10 parts of fly ash,

[0043] 10 parts of bentonite,

[0044] Sodium carboxymethyl cellulose 0.05 part,

[0045] 30 parts of water,

[0046] 3 parts water glass,

[0047] 1 serving of hemp.

[0048] In this embodiment, the bentonite used is organobentonite; the concentration of water glass is 42 Baume degrees; the sodium carboxymethyl cellulose is high-viscosity cotton fiber; the water is groundwater in the foundation pit, and its pH value is 7.1; The cement is P.O 42.5 grade Portland cement; the fly ash is Class II Class C fly ash; the hemp silk is hemp silk fiber.

[0049] The solidification time of the sealing material in this embodiment is 25s, and the strength is 2.43MPa.

[0050] A preparation method of the sealing material of the present embodiment, comprising the following steps:

[0051] (1) ...

Embodiment 2

[0057] A pore sealing material for karst water inflow of the present invention, comprising the following components by weight:

[0058] Portland cement 80 parts,

[0059] 10 parts of fly ash,

[0060] 15 parts of bentonite,

[0061] 0.1 part of sodium carboxymethyl cellulose,

[0062] 30 parts of water,

[0063] 5 parts of water glass,

[0064] 1 serving of hemp.

[0065] In this embodiment, the bentonite used is organobentonite; the concentration of water glass is 42 Baume degrees; the sodium carboxymethyl cellulose is high-viscosity cotton fiber; the water is groundwater in the foundation pit, and its pH value is 7.1; The cement is P.O 42.5 grade Portland cement; the fly ash is Class II Class C fly ash; the hemp silk is hemp silk fiber.

[0066] The solidification time of the sealing material in this embodiment is 35s, and the strength is 3.24MPa.

[0067] A preparation method of the sealing material of the present embodiment, comprising the following steps:

[0068]...

Embodiment 3

[0074] A pore sealing material for karst water inflow of the present invention, comprising the following components by weight:

[0075] Portland cement 80 parts,

[0076] 15 parts of fly ash,

[0077] 20 parts of bentonite,

[0078] 0.15 part of sodium carboxymethyl cellulose,

[0079] 40 parts of water,

[0080] 5 parts of water glass,

[0081] 1 serving of hemp.

[0082] In this embodiment, the bentonite used is organobentonite; the concentration of water glass is 42 Baume degrees; the sodium carboxymethyl cellulose is high-viscosity cotton fiber; the water is groundwater in the foundation pit, and its pH value is 7.1; The cement is P.O 42.5 grade Portland cement; the fly ash is Class II Class C fly ash; the hemp silk is hemp silk fiber.

[0083] The solidification time of the sealing material in this embodiment is 50s, and the strength is 3.56MPa.

[0084] A preparation method of the sealing material of the present embodiment, comprising the following steps:

[0085...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com