A kind of cement for underwater engineering

A technology of underwater engineering and cement, which is applied in the field of building materials, can solve the problems that the anti-dispersion ability of cement needs to be further improved, and achieve the effect of excellent anti-dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

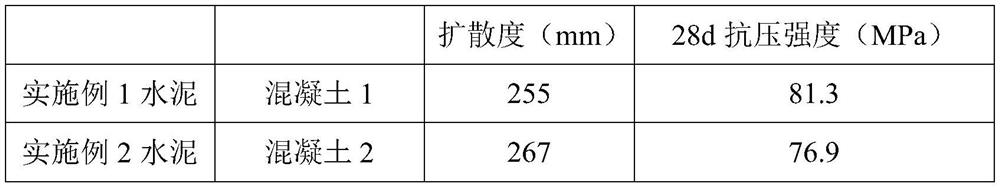

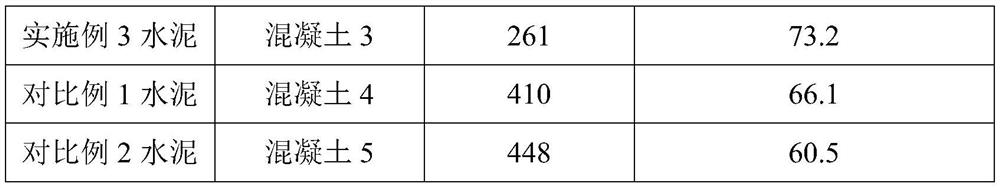

Examples

Embodiment 1

[0023] A cement for underwater engineering, which comprises the following components by weight:

[0024] 120 parts of cement (grade 42.5 Portland cement); 2 parts of polyacrylamide; 0.5 part of modified cellulose acetate.

[0025] Described modified cellulose acetate is prepared by the method comprising the following steps:

[0026] Add cellulose acetate, cardanol, 3-phenylpropionyl chloride and triethylamine in order in dioxane, then carry out heating and reflux reaction for 8h, after the reaction, add methanol dropwise in the reaction solution until no precipitation occurs; then take The modified cellulose acetate is obtained after the precipitation is dried. The dosage ratio of the dioxane, cellulose acetate, cardanol, 3-phenylpropionyl chloride and triethylamine is: 350mL:14g:10g:3g:7mL.

Embodiment 2

[0028] A cement for underwater engineering, which comprises the following components by weight:

[0029] Cement (grade 42.5 portland cement) 150 parts; polyacrylamide 2 parts; modified cellulose acetate 1 part.

[0030] Described modified cellulose acetate is prepared by the method comprising the following steps:

[0031] Add cellulose acetate, cardanol, 3-phenylpropionyl chloride and triethylamine in order in dioxane, then carry out heating and reflux reaction for 8h, after the reaction, add methanol dropwise in the reaction solution until no precipitation occurs; then take The modified cellulose acetate is obtained after the precipitation is dried. The dosage ratio of the dioxane, cellulose acetate, cardanol, 3-phenylpropionyl chloride and triethylamine is: 350mL:14g:10g:3g:7mL.

Embodiment 3

[0033] A cement for underwater engineering, which comprises the following components by weight:

[0034] 100 parts of cement (grade 42.5 Portland cement); 3 parts of polyacrylamide; 0.1 part of modified cellulose acetate.

[0035] Described modified cellulose acetate is prepared by the method comprising the following steps:

[0036] Add cellulose acetate, cardanol, 3-phenylpropionyl chloride and triethylamine in order in dioxane, then carry out heating and reflux reaction for 8h, after the reaction, add methanol dropwise in the reaction solution until no precipitation occurs; then take The modified cellulose acetate is obtained after the precipitation is dried. The dosage ratio of the dioxane, cellulose acetate, cardanol, 3-phenylpropionyl chloride and triethylamine is: 350mL:14g:10g:3g:7mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com