Quick coagulation flocculant for anti-washout concrete under water

A concrete and flocculant technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of prolonged coagulation time, insufficient anti-dispersion performance of underwater pouring mixture, and inability to meet the rapid construction of underwater concrete Engineering requirements and other issues, to achieve excellent filling, excellent anti-dispersion, reduce water pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

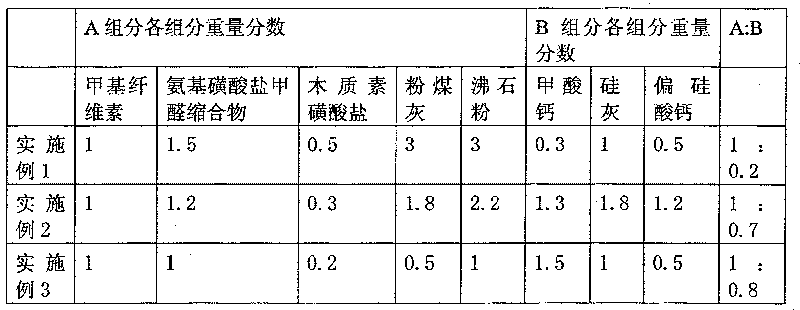

Embodiment 1~3

[0020]

[0021] Among them, the viscosity of methylcellulose in component A (mPa.s, 2% solution, 20°C) is 100,000, the pH value (1% solution at 25°C) is 7.2, and the gel temperature (°C) is 50.0-55.0; The acid-based water reducer is the sulfamate powder water reducer produced by Tianjin Yanshun Building Materials Co., Ltd.; the lignosulfonate is wood calcium, its lignin content is 96.5%, and the water insoluble matter is 1.2%. The content of zeolite is ≤13%, and the pH is 4.0-6.0; the fly ash used is a product above grade 2 provided by Tianjin Junliangcheng Power Plant, and the 45μm sieve ≤12%; the 45μm sieve of zeolite powder≤15%; B The silica fume used in the components is dense silica fume, and the sieve residue of 45 μm is ≤0.01%.

[0022] After the fast setting flocculant is added to the underwater non-dispersible concrete, the anti-dispersion performance of the concrete is significantly improved, especially the setting time of the concrete is significantly shortened, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com