A rapid emergency grouting plugging method for foundation pit water gushing

A foundation pit and grouting technology, which is applied in the direction of infrastructure engineering and construction, can solve the problems of water leakage on the side wall of the foundation pit, large flow and high pressure water gushing, collapse of the side wall of the foundation pit, etc., and achieve grouting sealing Save time, reduce economic losses, and ensure the quality of water plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

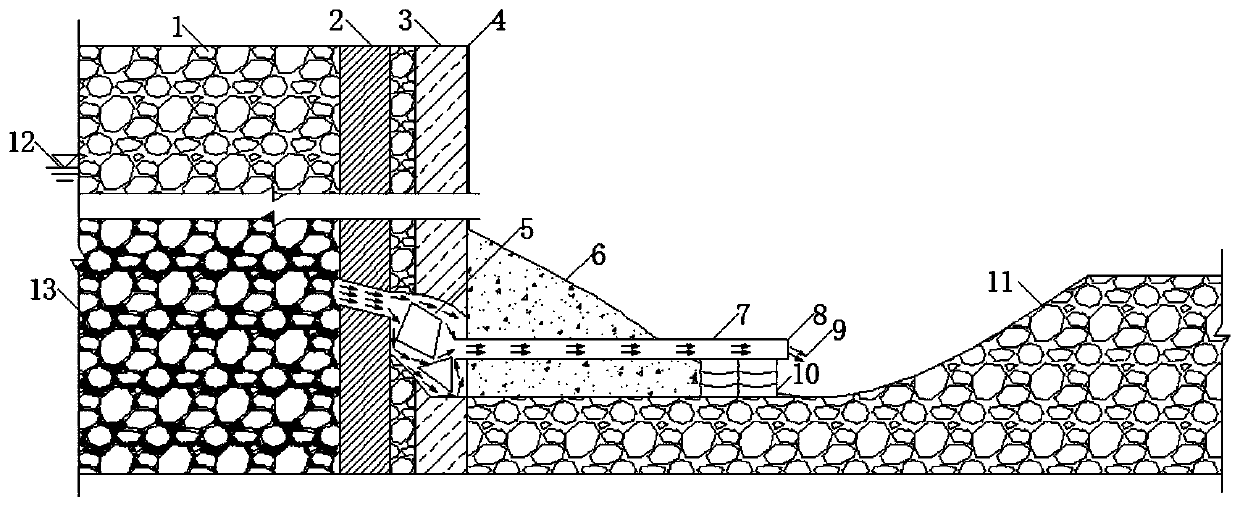

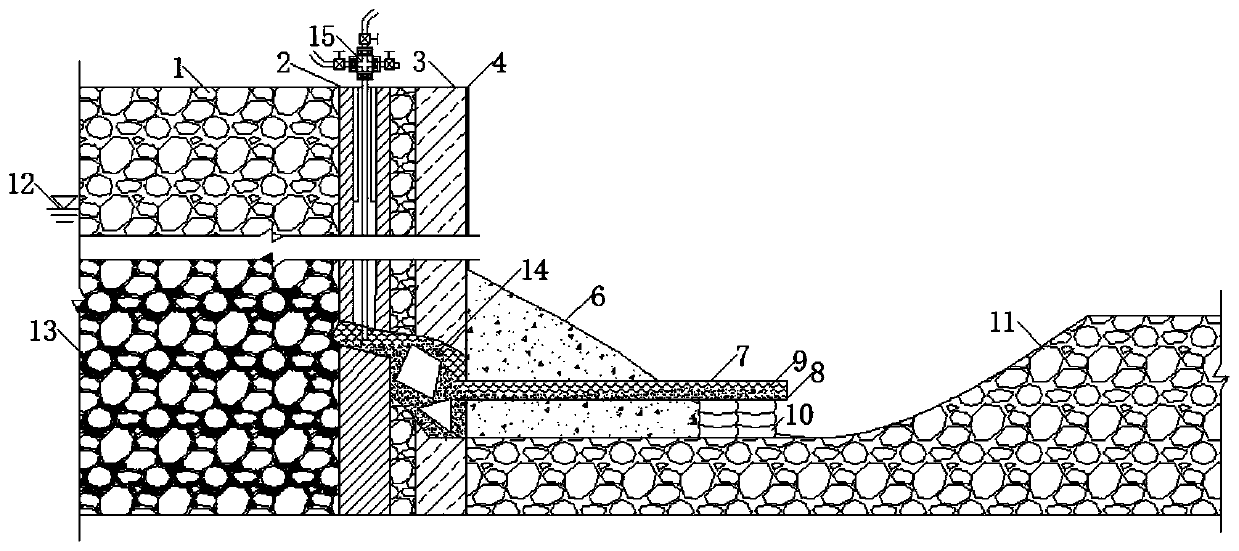

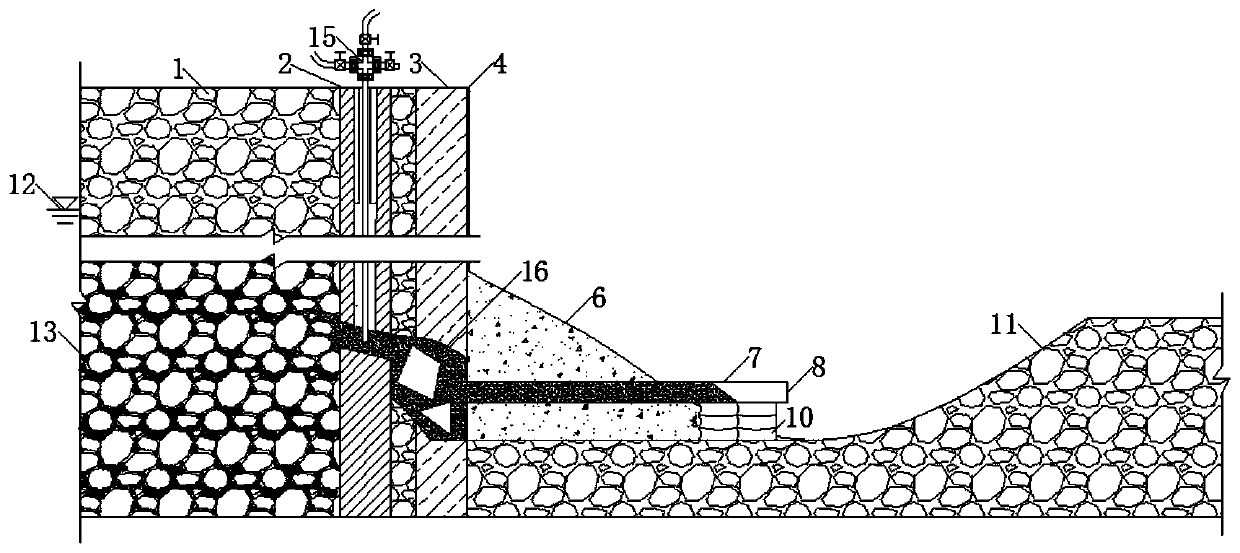

[0045] Lingshanwei Station of Qingdao Metro Line R3 is 195 meters long and is a two-story underground station; the long-distance open-cut section is 322 meters long and has a single-story frame structure. The landform is a coastal accumulation area, mostly composed of coastal sediments and river sediments, which is manifested as a coastal swamp landform. The original ground elevation of the station is +5.0m, and the strata from top to bottom are: 3m of plain fill, 3m of medium-coarse sand containing silt, 3m of silty clay, 6m of medium-coarse sand (mud content 8%), and cohesive gravel Sand 2.2m, strongly weathered tuff 2.6m. The basement is located at the junction of the gravel sand layer and the strongly weathered layer.

[0046] At 8 a.m. on May 23, 2016, when the western end of the foundation pit was dug down to -3.5m, two gushes of water were found on the side wall, pouring into the foundation pit along the piles, with a total flow of about 40m 3 / h, the average water pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com