Underwater anti-scouring environment-friendly composite material as well as preparation method and construction process thereof

A technology of composite materials and construction technology, which is applied in the direction of infrastructure engineering, sustainable waste treatment, solid waste management, etc., can solve the problems of wave flow erosion and corrosion of underwater platform foundations, and achieve strong anti-scourability, convenient construction, and anti-corrosion. strong dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Component A in this embodiment includes the following raw materials by weight: cement: 53 parts; epoxy resin: 0.69 parts; silica fume: 32 parts; nano-SiO 2 : 4 parts; fly ash: 9 parts. The prepared component A is used for the consolidation of seabed silt. The water content of the silt is 90%. 120g of this component A is added to each kilogram of silt and stirred evenly. The performance index of the prepared composite material is shown in Table 2. The physical properties are shown in Table 1.

[0062] Table 1 Physical properties of in situ seabed silt

[0063] index Moisture content / % Density / g / cm 3

Organic matter content / % Liquid limit / % Plastic limit / % result 90 1.53 1.09 53.1 26.8

[0064] The 3-hour fluidity detection method is as follows: apply Vaseline to the inner wall of the plexiglass cylinder, place it in the center of the transparent glass plate, stir the solidified soil added with the composite material evenly for 3 hour...

Embodiment 2

[0072] Component A in this embodiment includes the following raw materials by weight: cement: 53 parts; epoxy resin: 0 parts; silica fume: 35 parts; nano-SiO 2 : 4 parts; fly ash: 9 parts. The prepared component A is used for the consolidation of seabed silt, the water content of the silt is 90%, and 120 g of this component A is mixed with each kilogram of silt and stirred evenly.

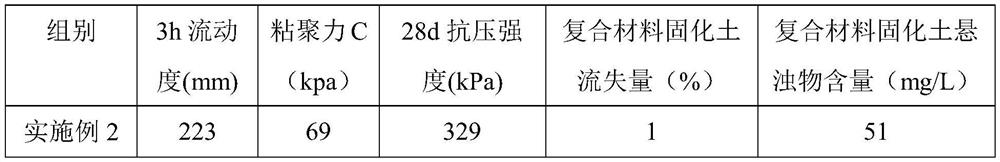

[0073] Table 3 The performance indexes of the prepared composite material solidified soil

[0074]

Embodiment 3

[0076] Component A in this embodiment includes the following raw materials by weight: cement: 53 parts; epoxy resin: 0.69 parts; silica fume: 35 parts; nano-SiO 2 : 4 parts; fly ash: 9 parts. The prepared component A is used for the consolidation of seabed silt, the water content of the silt is 90%, and 120 g of this component A is mixed with each kilogram of silt and stirred evenly. The performance index of the prepared composite material is shown in Table 3.

[0077] Table 4. The performance indexes of the composite solidified soil prepared in Table 4

[0078]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com