High-yield corn seed coating agent

A coating agent, corn technology, applied in the field of high-yield corn seed coating agent, can solve the problems of erosion resistance, poor water resistance, unsatisfactory use effect, affecting the application of coating agent, etc., to achieve strong erosion resistance, Effect of high film-forming strength and water absorption and water resistance and chemical stability, good film-forming and sustained-release function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

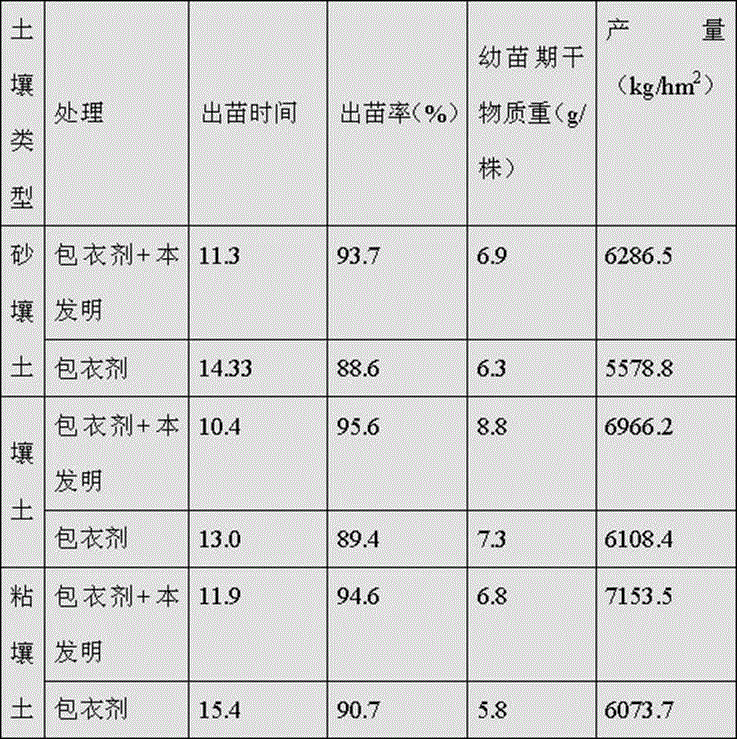

Examples

Embodiment 1

[0019] A high-yield corn seed coating agent is characterized in that each component of the raw material is composed as follows in parts by weight:

[0020] 5 parts of brassinolide, 13 parts of filler, 4 parts of gibberellin, 3 parts of 6-benzylaminopurine, 0.3 parts of plant growth regulator, 4 parts of salicylic acid, 12 parts of amino oligosaccharin, 3 parts of film forming agent part, 0.8 part of binder, 0.4 part of γ-polyglutamic acid, 0.06 part of polyoxyethylene alkyl ether, 0.3 part of thiophanate-methyl, and 0.2 part of imidacloprid.

[0021] Further, the film-forming agent is a mixture of chitosan, triacontanol and glycerin in a weight ratio of 1:3:5.

[0022] Further, the binder is a mixture of hydroxypropyl methylcellulose and methylcellulose in a mass ratio of 3:2.

[0023] Further, the filler is a mixture of brown algae, carbendazim, and talc in a weight ratio of 2:3:2.

[0024] Further, the plant growth regulator is a mixture of naphthaleneacetic acid, indoleac...

Embodiment 2

[0027] A high-yield corn seed coating agent is characterized in that each component of the raw material is composed as follows in parts by weight:

[0028] 6 parts of brassinolide, 14 parts of filler, 5 parts of gibberellin, 4 parts of 6-benzylaminopurine, 0.4 part of plant growth regulator, 5 parts of salicylic acid, 13 parts of amino oligosaccharin, 5 parts of film forming agent 1 part, 1 part of adhesive, 0.5 part of γ-polyglutamic acid, 0.07 part of polyoxyethylene alkyl ether, 0.4 part of thiophanate-methyl, and 0.3 part of imidacloprid.

[0029] Further, the film-forming agent is a mixture of chitosan, triacontanol and glycerin in a weight ratio of 1:3:5.

[0030] Further, the binder is a mixture of hydroxypropyl methylcellulose and methylcellulose in a mass ratio of 3:2.

[0031] Further, the filler is a mixture of brown algae, carbendazim, and talc in a weight ratio of 2:3:2.

[0032] Further, the plant growth regulator is a mixture of naphthaleneacetic acid, indolea...

Embodiment 3

[0035] A high-yield corn seed coating agent is characterized in that each component of the raw material is composed as follows in parts by weight:

[0036] 7 parts of brassinolide, 15 parts of filler, 6 parts of gibberellin, 5 parts of 6-benzylaminopurine, 0.5 part of plant growth regulator, 6 parts of salicylic acid, 14 parts of amino oligosaccharin, 6 parts of film forming agent 1.2 parts, 1.2 parts of adhesive, 0.6 parts of γ-polyglutamic acid, 0.08 parts of polyoxyethylene alkyl ether, 0.5 parts of thiophanate-methyl, and 0.4 parts of imidacloprid.

[0037] Further, the film-forming agent is a mixture of chitosan, triacontanol and glycerin in a weight ratio of 1:3:5.

[0038] Further, the binder is a mixture of hydroxypropyl methylcellulose and methylcellulose in a mass ratio of 3:2.

[0039] Further, the filler is a mixture of brown algae, carbendazim, and talc in a weight ratio of 2:3:2.

[0040] Further, the plant growth regulator is a mixture of naphthaleneacetic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com