Glucose high-polymer marine concrete anti-dispersion agent and preparation method thereof

A marine concrete and anti-dispersant technology, which is applied in the field of glucose high polymer marine concrete anti-dispersant, can solve the problems of unfavorable concrete materials such as large-scale use, high price, and difficult production and supply of cellulose, and achieve simple manufacturing process, Low cost, low impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

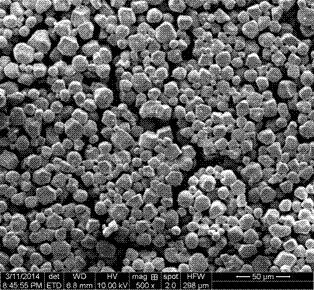

Image

Examples

Embodiment Construction

[0012] 1 Glucose high polymer marine concrete anti-dispersant, the mass ratio of raw materials is starch: water: ethanol: chloroacetic acid: sodium hydroxide = 100:300:200:50:10, and its preparation method is to mix ethanol, chloroacetic acid After mixing with water, heat up to 50°C, add sodium hydroxide and starch, stir at a speed of 100 rpm, heat to 80°C, keep warm for 1 minute, cool down, and filter and dry the finished product.

[0013] Table 1 shows the comparative test of the slump and expansion of the glucose high polymer marine concrete anti-dispersant of the present invention and the existing polyacrylamide flocculants (PAM) and cellulose flocculants (HPMC).

[0014]

[0015] Table 1 Concrete work performance

[0016]

[0017] The concrete mix ratio is shown in Table 2.

[0018] Table 2 Concrete mix ratio

[0019]

[0020] The anti-dispersion agent of glucose high polymer marine concrete of the present invention and the existing polyacrylamide flocculant (PAM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com