Fluorite pellet production method

A production method, the technology of fluorite pellets, applied in the field of fluorite pellet production, can solve the problems of increasing the company's production cost, low production efficiency of fluorite pellets, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

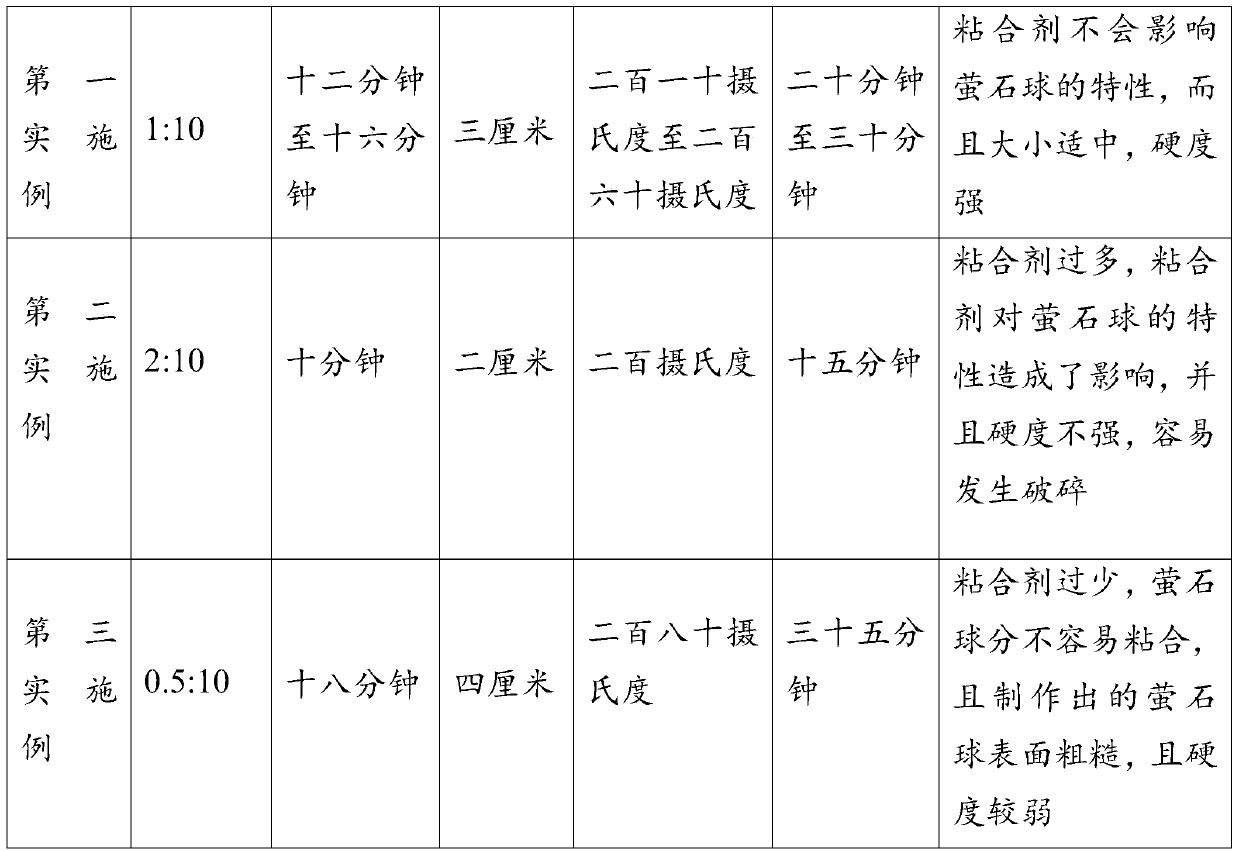

no. 1 example

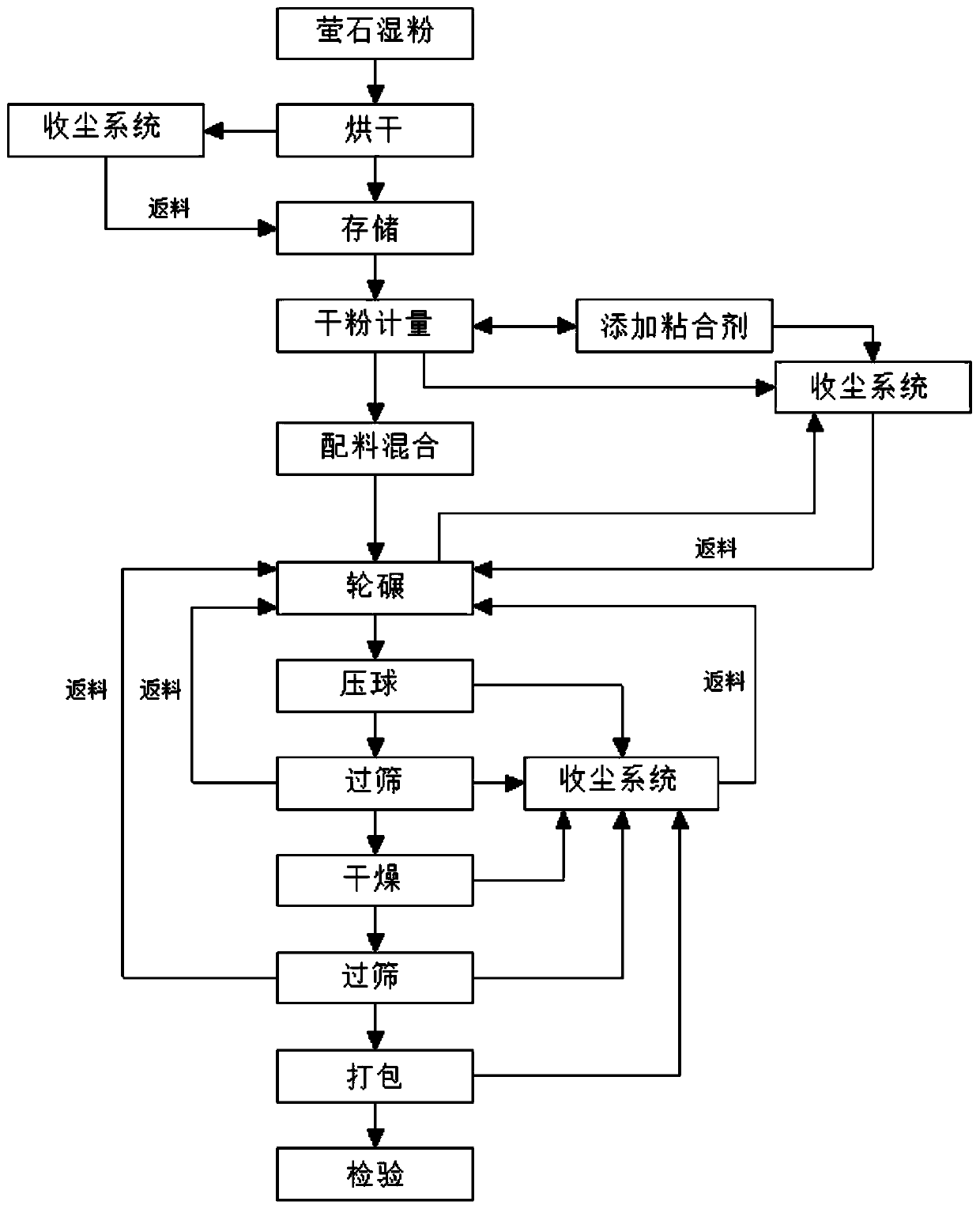

[0031] Please refer to figure 1 ,in, figure 1 It is a diagram of the production steps of a preferred embodiment of the method for producing fluorite pellets provided by the present invention. Fluorite pellet production method comprises the following steps:

[0032] S1. Prepare fluorite wet powder, prepare one ton of fluorite wet powder;

[0033] S2. Pour the prepared wet fluorite powder into the interior of the rotary kiln, and dry the wet fluorite powder through the rotary kiln. The wet fluorite powder can be dried quickly through the rotary kiln, and the drying effect is good. The wet stone powder is heated evenly;

[0034] S3. Prepare a storage container, then discharge the fluorite powder dried in the rotary kiln in S2 to the interior of the storage container, and absorb the dust generated by drying in S2 through the dust collection system, and discharge it to the interior of the storage container , the dried fluorite powder can be well stored through the storage conta...

no. 2 example

[0056] S1, prepare fluorite wet powder;

[0057] S2. Pour the prepared fluorite wet powder into the inside of the rotary kiln, and dry the fluorite wet powder through the rotary kiln;

[0058] S3, prepare a storage container, and then discharge the fluorite powder dried in the rotary kiln in S2 to the inside of the storage container;

[0059] S4, pour the fluorite powder in the storage container in S3 into the inside of the dry powder metering machine, and perform the metering work through the dry powder metering machine;

[0060] S5. Pour the fluorite powder measured by the dry powder measuring machine in S4 into the interior of the mixer, and pour the adhesive into the interior of the mixer, and then fully mix and stir the adhesive and the fluorite powder through the mixer, so that Form the main material of fluorite;

[0061] S6. Pour the stirred main ingredients into the inside of the wheel mill, and crush or knead the main ingredients through the wheel mill;

[0062] S7...

no. 3 example

[0076] S1, prepare fluorite wet powder;

[0077] S2. Pour the prepared fluorite wet powder into the inside of the rotary kiln, and dry the fluorite wet powder through the rotary kiln;

[0078] S3, prepare a storage container, and then discharge the fluorite powder dried in the rotary kiln in S2 to the inside of the storage container;

[0079] S4, pour the fluorite powder in the storage container in S3 into the inside of the dry powder metering machine, and perform the metering work through the dry powder metering machine;

[0080] S5. Pour the fluorite powder measured by the dry powder measuring machine in S4 into the interior of the mixer, and pour the adhesive into the interior of the mixer, and then fully mix and stir the adhesive and the fluorite powder through the mixer, so that Form the main material of fluorite;

[0081] S6. Pour the stirred main ingredients into the inside of the wheel mill, and crush or knead the main ingredients through the wheel mill;

[0082] S7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com