Production method of humic-acid compound fertilizer

A production method, humic acid technology, applied in the direction of fertilization device, fertilizer mixture, application, etc., can solve the problems of low agricultural production cost, inability to fully exert functions, poor activation of humic acid, etc., and achieve good use value and Market prospect, outstanding environmental protection function, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

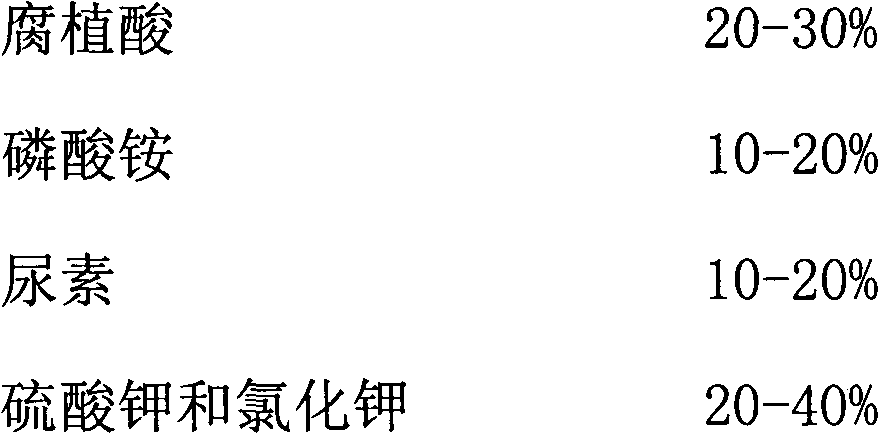

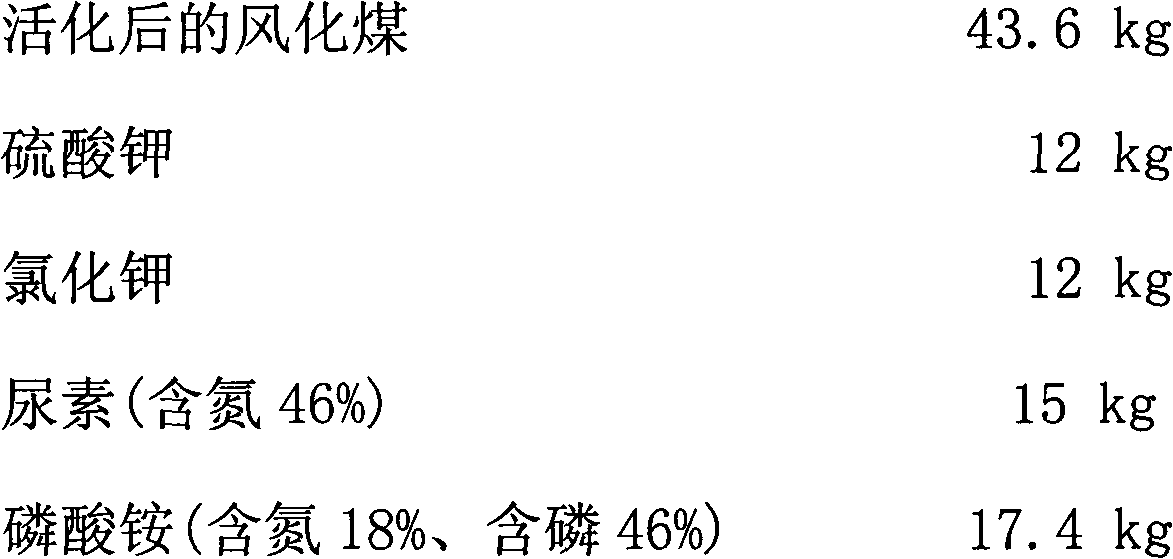

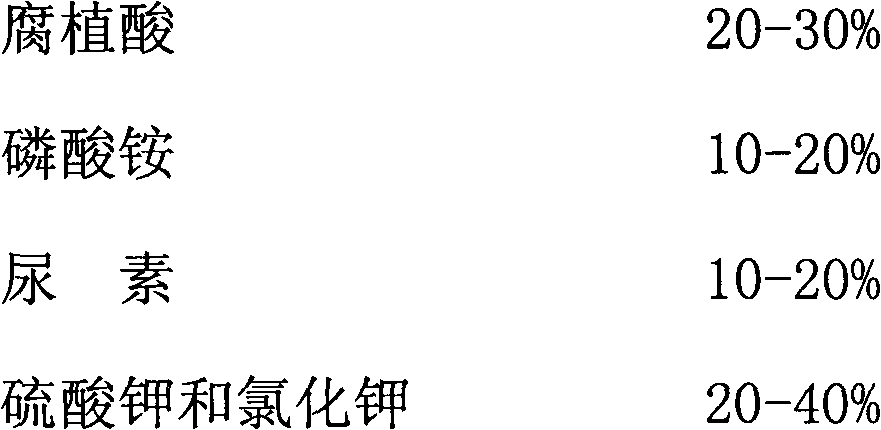

[0014] Take the production of 100kg of humic acid compound fertilizer containing 30% of nitrogen, phosphorus and potassium as an example, the formula is as follows:

[0015]

[0016] The process flow is as follows:

[0017] The activated weathered coal is pulverized to 80 mesh in a pulverizer. Activate the pulverized weathered coal in the mixer → add water to the activated weathered coal to a water content of 70-80% → put potassium sulfate, potassium chloride, urea, and ammonium phosphate into the mixer and stir well → put it into the reaction kettle, at 50 ° C Insulate at -60°C for 2-3 hours, so that the water content of the reactants in the kettle is 30-35% → enter the granulator for granulation → enter the dryer for drying and cooling (drying, the inlet temperature of the cooler is 150°C , the outlet temperature is the normal temperature of the workshop) → screening → packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com