Gradual-change cavity microperforated broad band sound absorption type sound barrier

A micro-perforation and sound barrier technology, applied in the field of acoustics, can solve the problems of narrow sound absorption frequency band, high temperature resistance, poor weather resistance, etc., and achieve the effect of sound absorption frequency band, good noise reduction effect, and superior weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

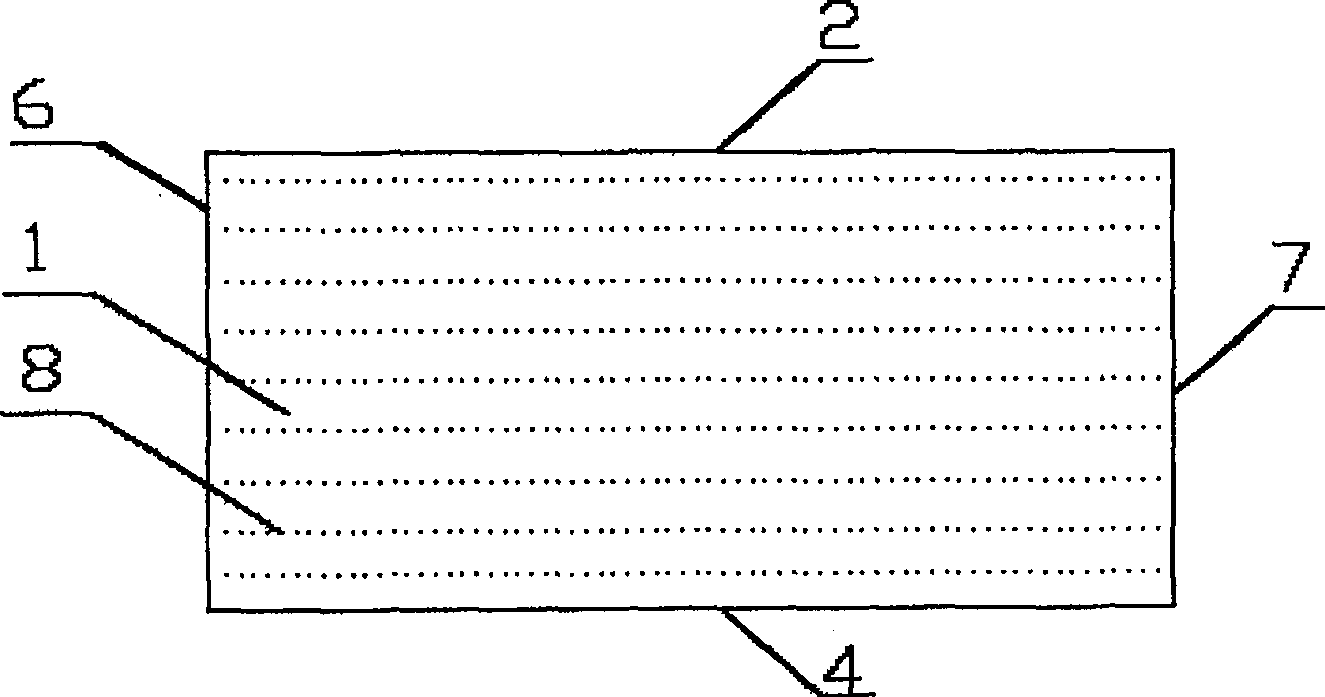

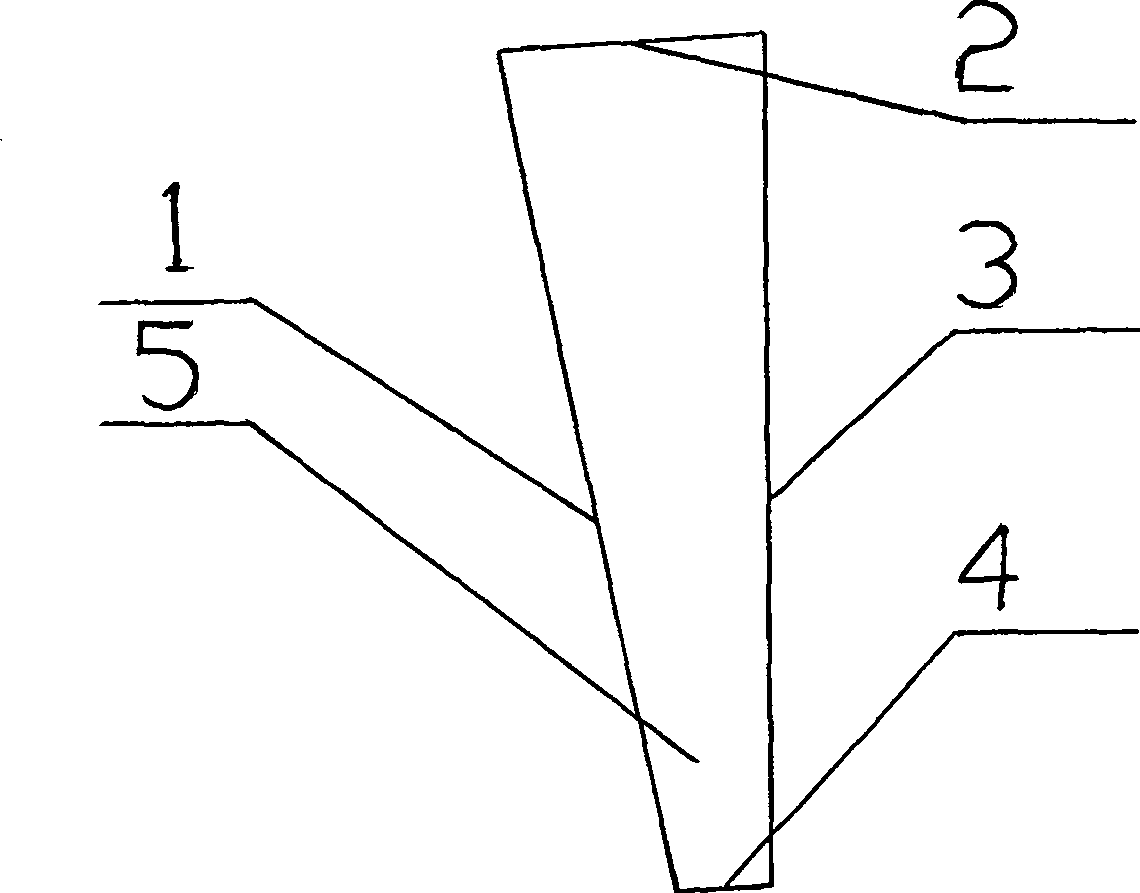

[0021] Embodiment 1: the following parts are pressed Figure 1-Figure 2 Those skilled in the art can successfully implement the connection in the manner shown. The micro-perforated panel 1 , the upper end surface 2 , the back plate 3 , the lower end surface 4 , the left end surface 6 , and the right end surface 7 are connected to form a closed cavity 5 . The micro-perforated panel 1 is made of 1mm thick alumina plate. The size of the micro-perforated panel 1 is 1.0m in length and 0.503m in width. 0.8mm. The back plate 3 is made of 1.2mm thick steel plate, the upper end face 2, the lower end face 4, the left end face 6, and the right end face 7 are made of 1 mm thick aluminum plate. ~15cm linear gradient. The angle between the upper end surface 2 and the water line is 4°, the angle between the lower end surface 4 and the horizontal line is 4°, and the angle between the micro-perforated panel 1 and the vertical line is 11°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com