Surface configuration and acoustic impedance dicycle mutation microporous ultra-broadband sound absorption structure

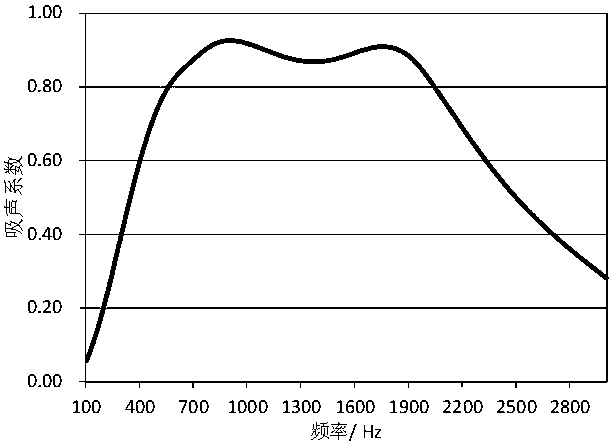

A technology of micro-perforation and acoustic impedance, applied in the field of acoustics, can solve the problems of less than two, large volume, narrow sound absorption frequency band, etc., and achieve the effect of simple device, high sound absorption coefficient, and sound absorption frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

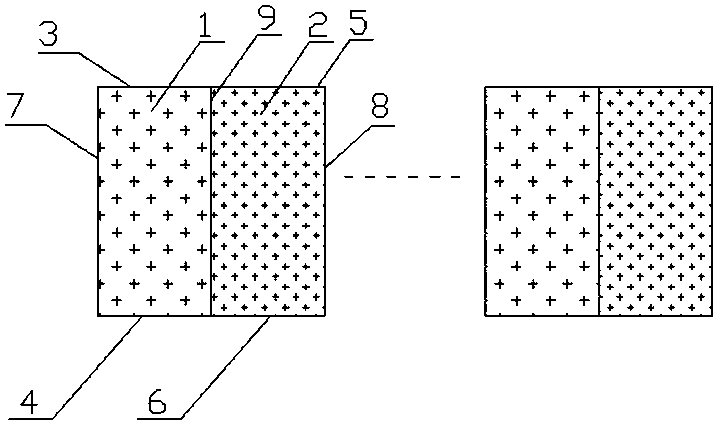

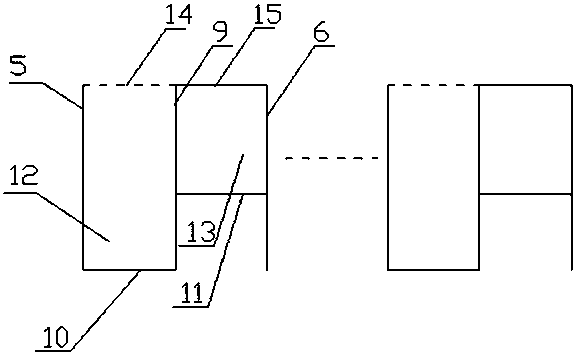

[0027] Embodiment 1: the following parts are pressed Figure 1~Figure 2 Those skilled in the art can easily and smoothly implement the connection in the manner shown. Unit A micro-perforated panel 1, unit B micro-perforated panel 2, unit A front face 3, unit A rear end face 4, unit B front face 5, unit B rear end face 6, left end face 7, right end face 8, unit partition 9 , the unit A bottom plate 10 and the unit B bottom plate 11 are connected to form a unit A closed cavity 12 and a unit B closed cavity 13 . Unit A micro-perforated panel 1 is made of 0.3-0.5mm thick steel plate with a size of 0.5m in length and 0.08m in width. There are 2000-3500 unit A micro-holes 14 with a diameter of 0.3-0.5mm distributed on unit A micro-perforated panel 1 . The unit B micro-perforated panel 2 is made of 0.3-0.5mm thick steel plate with a size of 0.5m in length and 0.08m in width. There are 2000-3500 unit B micro-holes 15 with a diameter of 0.3-0.5mm distributed on the unit B micro-perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com