Acoustical insulation sound-deadening pipe used for on-site noise measurement and recognition

A technology of noise measurement and muffler tube, which is applied in the field of acoustics, can solve the problems of providing reliable basis, difficult measurement, and large noise impact, and achieves the effects of superior sound insulation performance, simple measurement, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

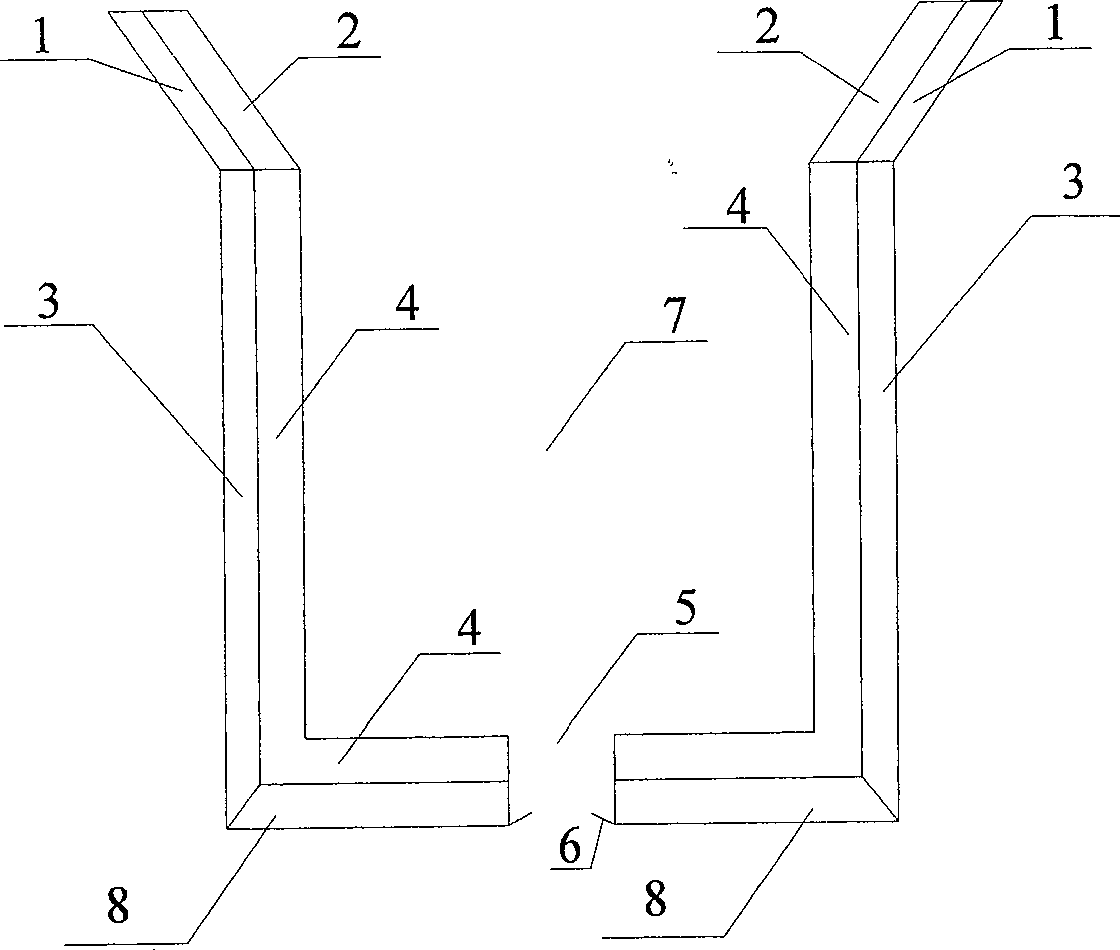

[0019] Embodiment 1: the following parts are pressed figure 1 Those skilled in the art can successfully implement the connection in the manner shown. The elastic connection section 1, the wall plate composed of multi-layer aluminum plate damping light sound insulation structure 3, the bottom plate 8 composed of multi-layer aluminum plate damping light sound insulation structure are connected to form a barrel-shaped cavity 7, and the multi-layer aluminum plate damping The bottom microphone hole 5 is set in the middle of the bottom plate 8 of the lightweight sound insulation structure, and the elastic sealing sheet 6 for the microphone hole is installed. The elastic connection section 1 in the cavity shows that it is close to the first sound-absorbing sponge 2, and the lightweight sound insulation structure is damped by the multi-layer aluminum plate. The surface of the wall plate 3 and the bottom plate 8 of the multi-layer aluminum plate damping light-weight sound-insulating st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com