Biomass carbonization molding material and preparation method thereof

A technology of biomass materials and molding materials, applied in the direction of biofuels, chemical instruments and methods, separation methods, etc., can solve problems that are not conducive to large-scale practical production applications, increase production costs, and difficult process control, etc., to achieve good mechanical strength And environmental protection function, reduce environmental pressure, good effect of carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, the preparation method of biomass carbonization molding material (brick):

[0035] Bamboo (with a moisture content of about 10%) is pulverized to obtain a powder with a particle size of 100 mesh, and then mixed uniformly with an appropriate amount of clay (with a moisture content of about 10% and a particle size of 200 mesh) to obtain a mixed material; the above two Their weight ratio is controlled at 15 / 85 (that is, the weight content of bamboo in the mixed material is 15%, and the weight content of clay in the mixed material is 85%). Then add water accounting for 10% of the total weight of the mixed material, and mix and stir for 2 hours. The resultant is injected into a mold and pressed into a mold (for example, pressed into a biomass carbonized brick of 600×600×200 mm), and dried at room temperature for 24 hours after demolding (moisture content ≤ 8%); After burning for 8 hours and cooling to room temperature, the final biomass carbonized molding mate...

Embodiment 2

[0036] Embodiment 2: Change the temperature of the smoldering treatment in Embodiment 1 to 1200° C., and the rest are equal to Embodiment 1.

Embodiment 3

[0037] Embodiment 3: Change the temperature of the smoldering treatment in Embodiment 1 to 1300° C., and the rest are equal to Embodiment 1.

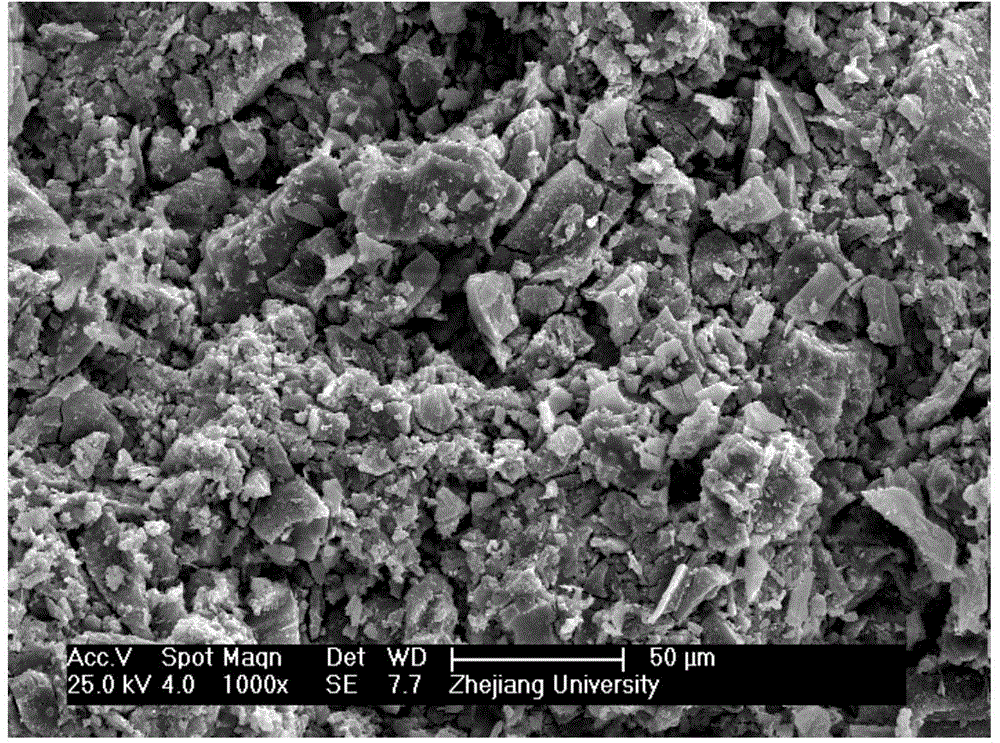

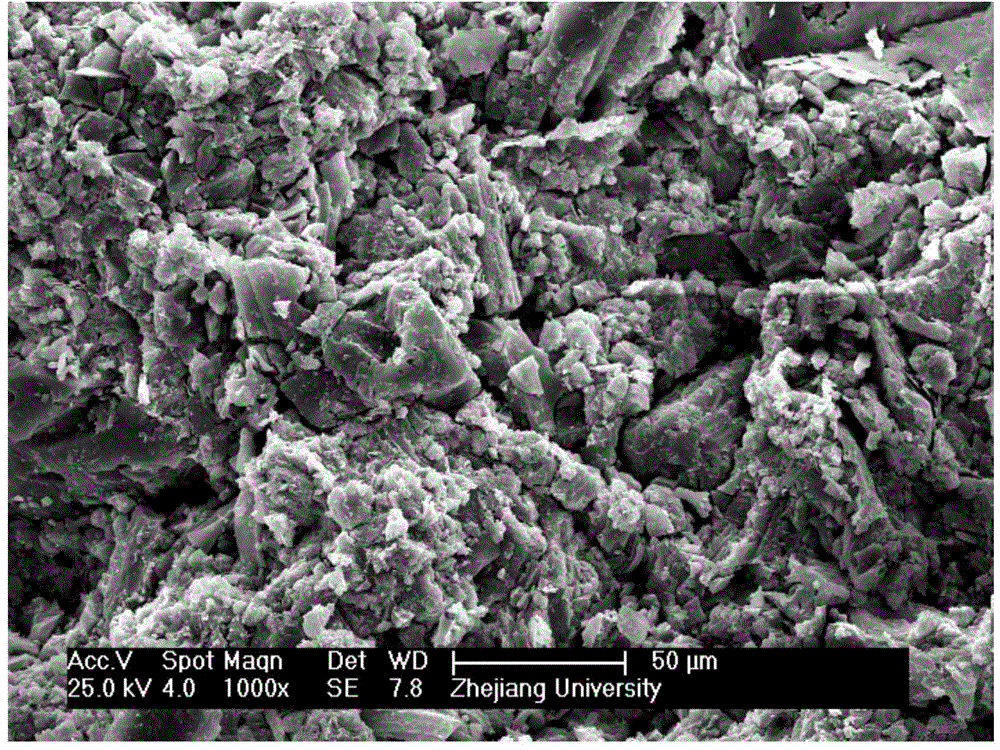

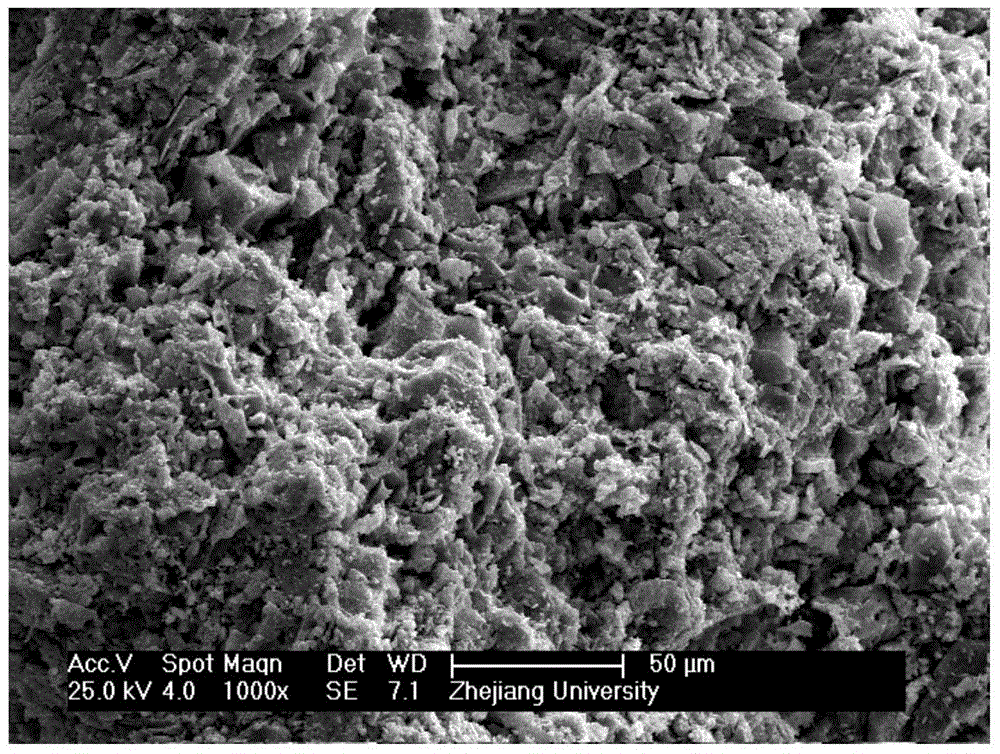

[0038] The 1000 times scanning electron microscope photos of the carbonized decorative bricks prepared in the above-mentioned embodiments 1 to 3 are as follows: Figure 1 ~ Figure 3 shown;

[0039] according to Figure 1 ~ Figure 3 We can know that: within the range set by the present invention, the higher the sintering temperature, the denser the material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com