Ultraviolet light-moisture-heat triple curable automobile aqueous intermediate coat and preparation method thereof

A compound and composition technology, which is applied in the field of ultraviolet-moisture-heat triple curing automotive water-based intermediate coating composition and its preparation, can solve the problems that it is difficult to ensure the curing of automotive intermediate coatings, and achieve excellent impact resistance and save energy. Energy, effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

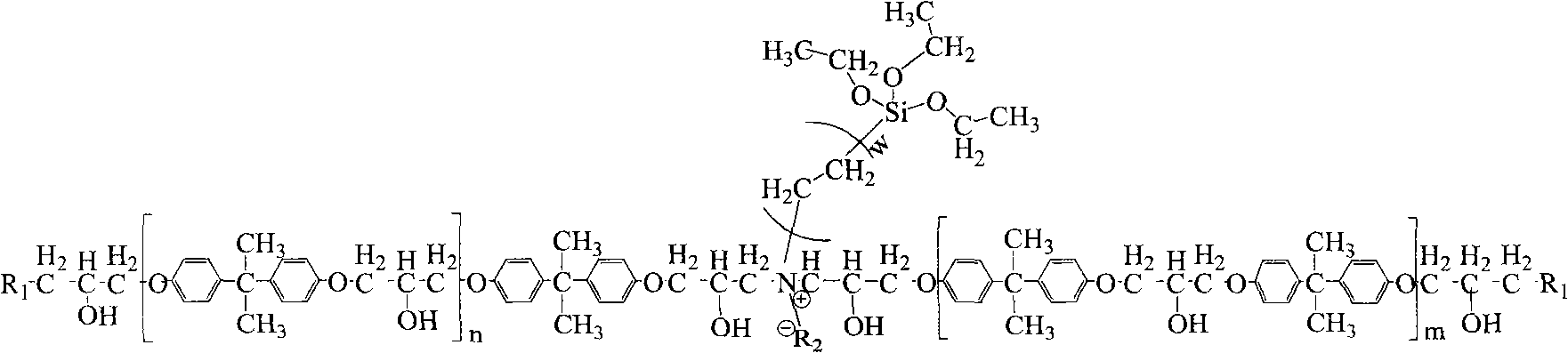

[0034] Example 1: Mix 35g of epoxy resin E44 and 11.4g of acrylate, add 0.02g of tetrabutylammonium bromide, and react at 85°C to 90°C for 3 hours to obtain the first intermediate product;

[0035] Add 100ml of butanone and 3g of aminopolyethylene glycol siloxane to the first intermediate product at 35°C, and continue the reaction to obtain the second intermediate product;

[0036] Add 2g of hydrochloric acid to the second intermediate product at 25°C and 30°C, stir and neutralize, then remove butanone to obtain modified epoxy acrylate.

Embodiment 2

[0037] Example 2: Mix 30g of epoxy resin E51 and 11.2g of acrylate, add 0.02g of tetrabutylammonium bromide, and react at 85°C to 90°C for 3 hours to obtain the first intermediate product;

[0038] Add 100ml of butanone and 5g of aminopolyethylene glycol siloxane to the first intermediate product at 35°C to 40°C, and continue the reaction to obtain the second intermediate product;

[0039] Add 2.2 g of sulfuric acid to the second intermediate product at 25° C. to 30° C., stir and neutralize, then remove methyl ethyl ketone to obtain modified epoxy acrylate.

Embodiment 3

[0040] Example 3: Mix 42g of epoxy resin E12 and 4.4g of methacrylate, add 0.03g of tetrabutylammonium bromide, and react at 85°C for 3h to obtain the first intermediate product;

[0041] At 40°C, add 150ml methyl ethyl ketone and 2.6g aminopolyethylene glycol siloxane to the first intermediate product, and continue the reaction to obtain the second intermediate product;

[0042] Add 1.8 g of acetic acid to the second intermediate product at 30° C., stir and neutralize, then remove methyl ethyl ketone to obtain modified epoxy acrylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com