Double-layer composite micropunch sound absorption method and sound absorption panel

A double-layer composite and micro-perforation technology, which is applied in the direction of sound-generating devices and instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

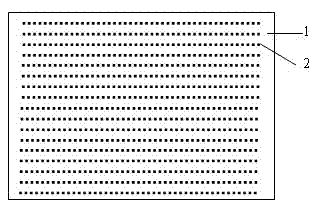

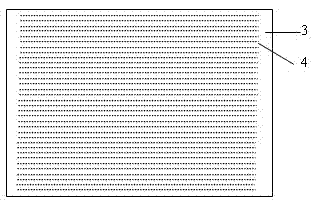

Image

Examples

Embodiment 1

[0044] The double-layer composite micro-perforated sound-absorbing structure is supported by two grooved columns 6, the backplane structure 7, the membrane support structure 8 and the micro-perforated substrate 9 are stuck between the grooved columns 6, and the two grooves are fixed by screws. Carry out lateral fixation on the four corners of column 6. The microperforated membrane 3 is adhered to a membrane support structure 8 . In use, the micro-perforated substrate 9 of the structure faces the direction of the sound source.

[0045] The purpose of this embodiment is to enable those skilled in the art to understand and implement the technical solutions of the present invention, and not to limit the protection scope of this patent. within the scope of protection of the invention.

[0046] The sound barrier provided by the present invention can also be made into other sizes, specifications and shapes that meet the requirements of the place of use, and it only needs to be inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com