Method for determining composition ratio range of rubber particle asphaltum mixture

A technology of asphalt mixture and rubber granules, which is applied to building insulation materials, building components, instruments, etc., can solve the problem that the gradation composition range of asphalt mixture cannot meet the requirements of the ratio range of rubber granule asphalt mixture components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

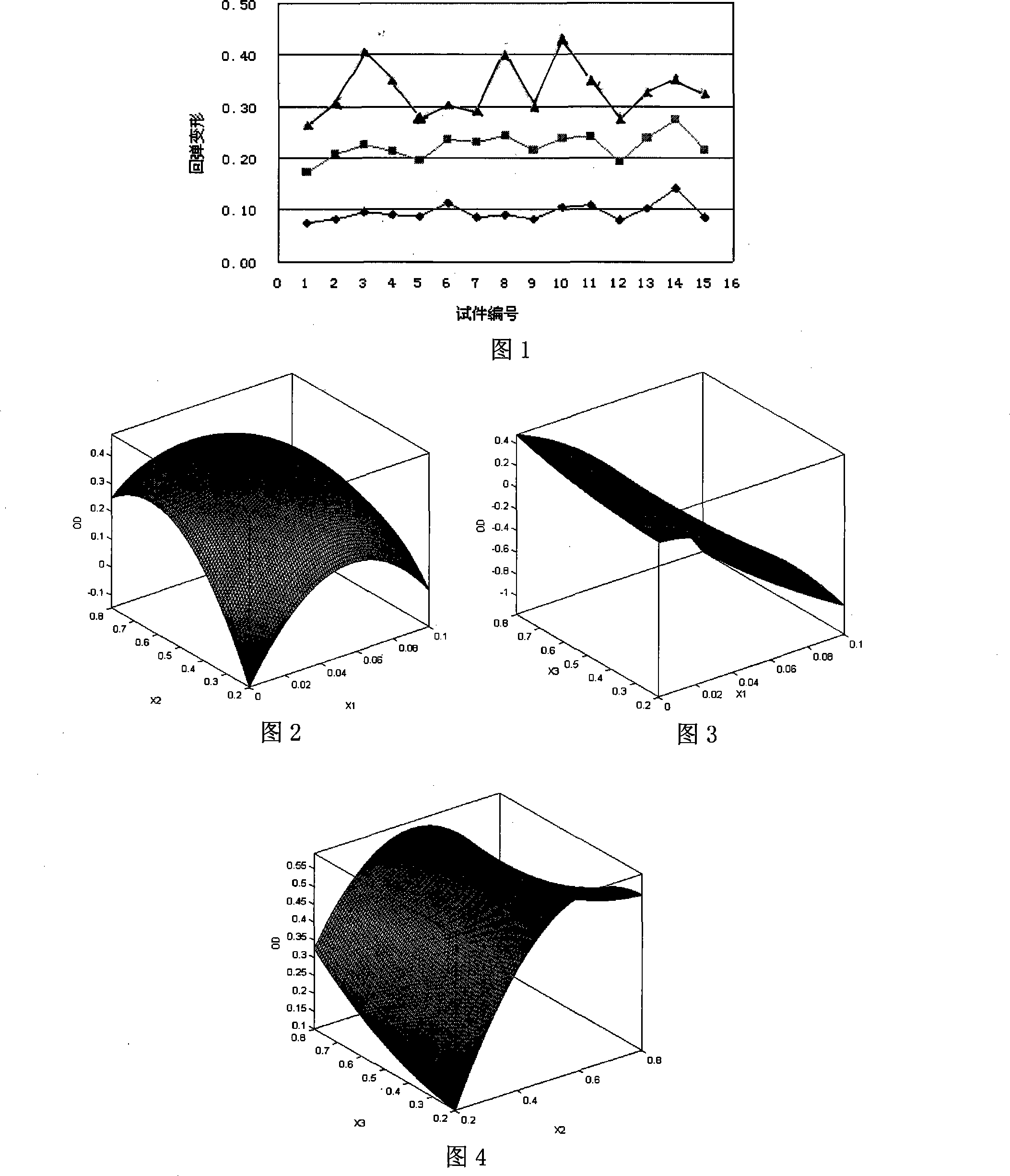

[0006] Specific implementation mode one: the method for determining the mixing ratio range of the rubber particle asphalt mixture in this embodiment is realized through the following steps: 1. When the quality of the rubber particle asphalt mixture is certain, three factors are set, that is, according to the pre-test , set the amount of rubber particles as 1% to 7% of the mass of the mixture, and set the amount of rubber particles as X 1 (mass%), the amount of coarse stone is set at 20% to 80% of the mass of the mixture, and the amount of coarse stone is set to X 2 (mass %), the coarse rubber particle dosage of 2.36~5mm is determined as 20%~80% of the rubber particle quality, and the coarse rubber particle dosage is set as X 3 (mass %); Two, fully mix asphalt, be the rubber granule of 4% of mixture quality, be the coarse stone material of 50% of mixture quality and be the coarse rubber granule of 50% of rubber granule quality, obtain rubber granule under different acting force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com