High-modulus asphalt concrete material doped with coal gasification slag and preparation method thereof

A technology for asphalt concrete and coal gasification slag, which is used in climate sustainability, sustainable waste treatment, solid waste management, etc. Improves elastic and stiffness moduli and reduces the effect of accumulated deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

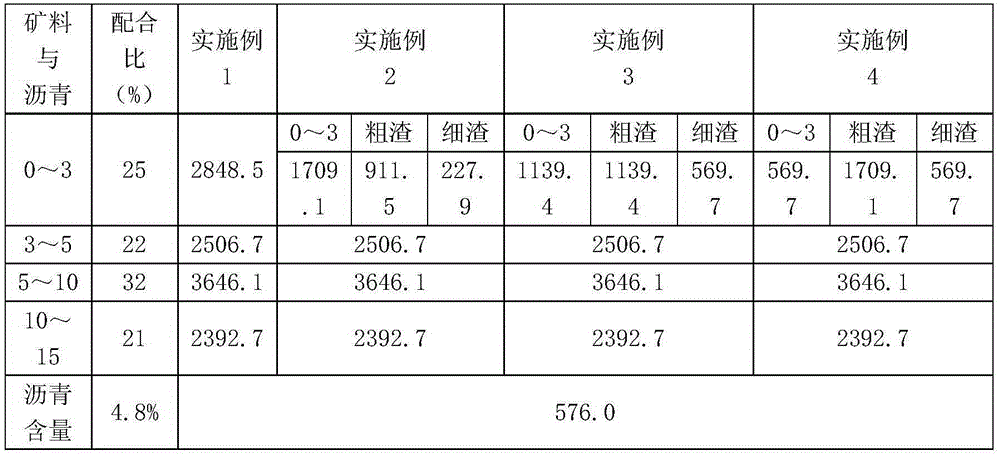

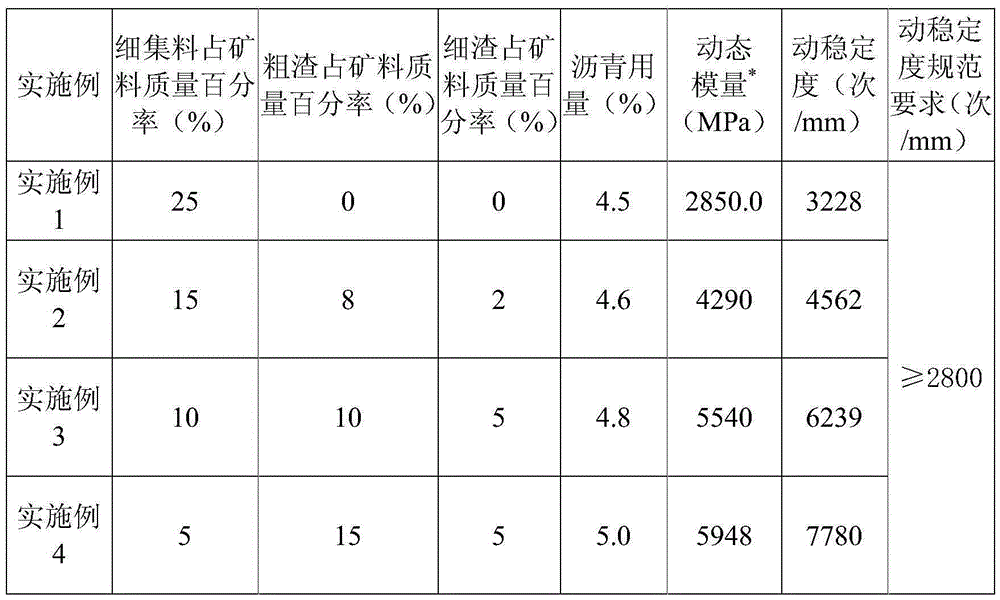

[0033] The present invention will be further described below in conjunction with the embodiment of AC-13 type high modulus asphalt concrete.

[0034] A high modulus asphalt concrete material mixed with coal gasification slag, comprising the following materials in proportion by weight:

[0035] 4.5-5.5 parts of polymer modified asphalt, 80-88 parts of aggregate

[0036] 10-20 parts of coal gasification slag 0.2-0.3 parts of polyacrylonitrile fiber

[0037] Polymer modified asphalt is SBS modified asphalt, which belongs to the I-B series of SBS modified asphalt listed in "Technical Specification for Construction of Highway Asphalt Pavement JTGF40-2004".

[0038] The AC-13 type asphalt concrete aggregate is a common stone material for highway asphalt pavement, which is diabase stone material, and is divided into four grades of specifications: 0-3mm, 3-5mm, 5-10mm and 10-15mm.

[0039] The coal gasification slag is divided into fine slag and coarse slag: the element composition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com