Phyllosilicate nano modified asphalt by dual processing of intercalation and coupling and preparation method thereof

A nano-modified, silicate technology, used in building components, building insulation materials, buildings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

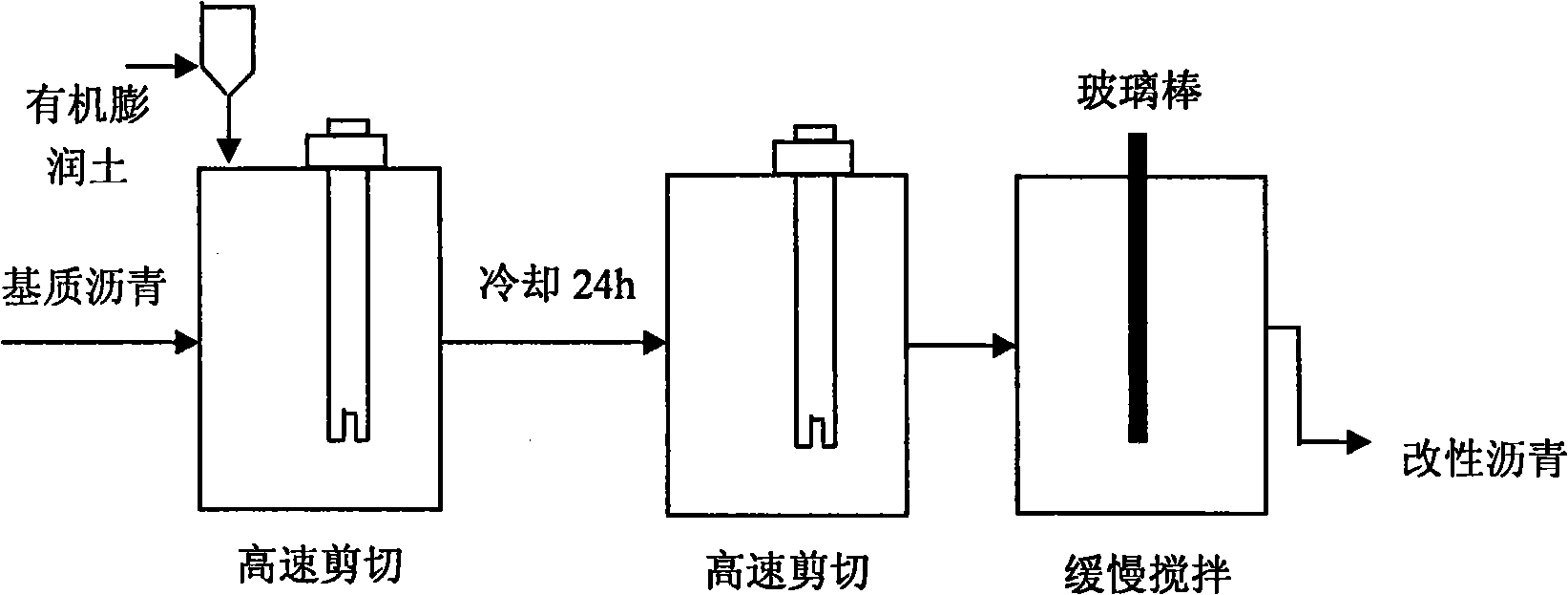

Method used

Image

Examples

Embodiment 1

[0030] The composition of embodiment 1 nano-modified asphalt

[0031] In an embodiment, the layered clay silicate, the water-soluble organic cation intercalation agent, and the coupling agent respectively adopt bentonite, dioctadecyltrimethylammonium bromide or / octadecyltrimethylammonium chloride and γ-aminopropyltriethoxysilane (abbreviated as KH550), by mass ratio, bentonite: dioctadecyltrimethylammonium bromide or / octadecyltrimethylammonium chloride: γ-aminopropyl Triethoxysilane is 1:0.6:0.01 to form organic layered clay silicate, and the mass ratio of organic layered clay silicate to asphalt is 0.04:1.

Embodiment 2

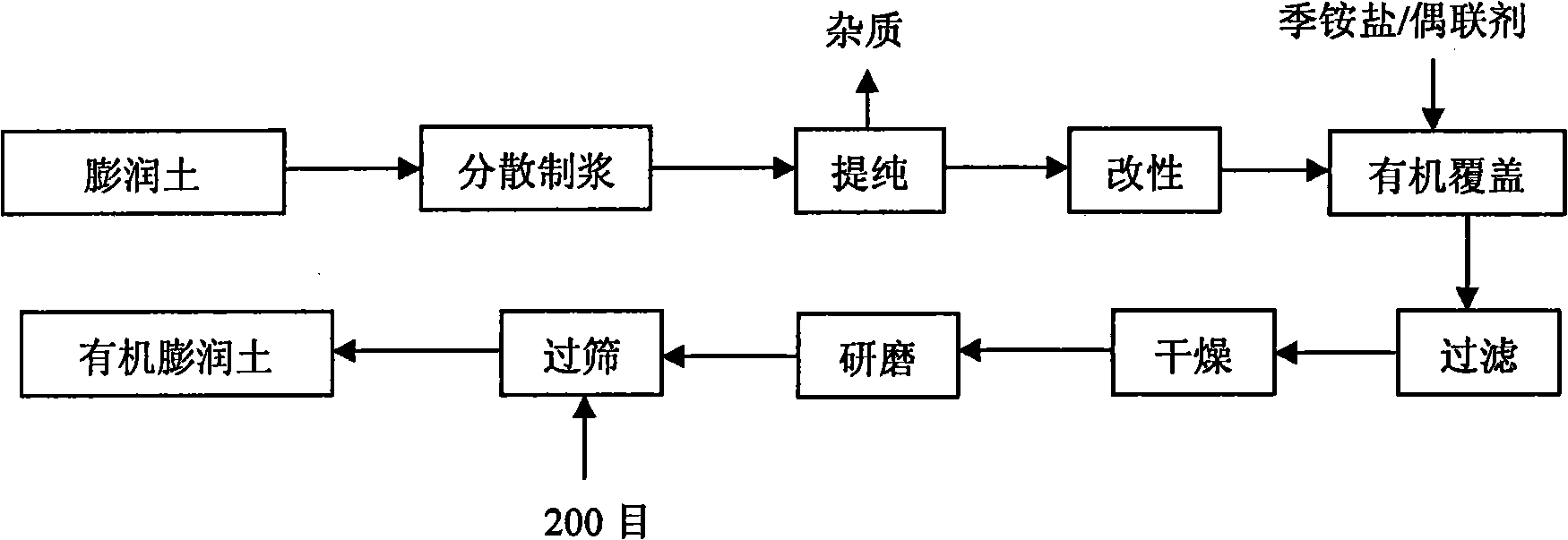

[0032] Embodiment 2 intercalation principle, process and method

[0033](1) Principle: The structural characteristics of bentonite determine that one of its main characteristics is the cation exchange performance of bentonite. The introduction of organic cations increases the interlayer spacing of montmorillonite and increases the organic phase, which has a significant impact on the adsorption characteristics of montmorillonite; secondly, quaternary ammonium salt surfactants are easy to enrich because of their amphiphilic molecular structure. A variety of ordered molecular assemblies are formed on the surface and in the solution. This special structural feature enables it to be used in the surface modification of bentonite, that is, the physical and chemical interactions between the hydrophilic group and the surface of the silicic acid sheet, adsorption On the surface of the particles, the lipophilic group faces outward, making the surface of the sheet layer change from hydrop...

example 3

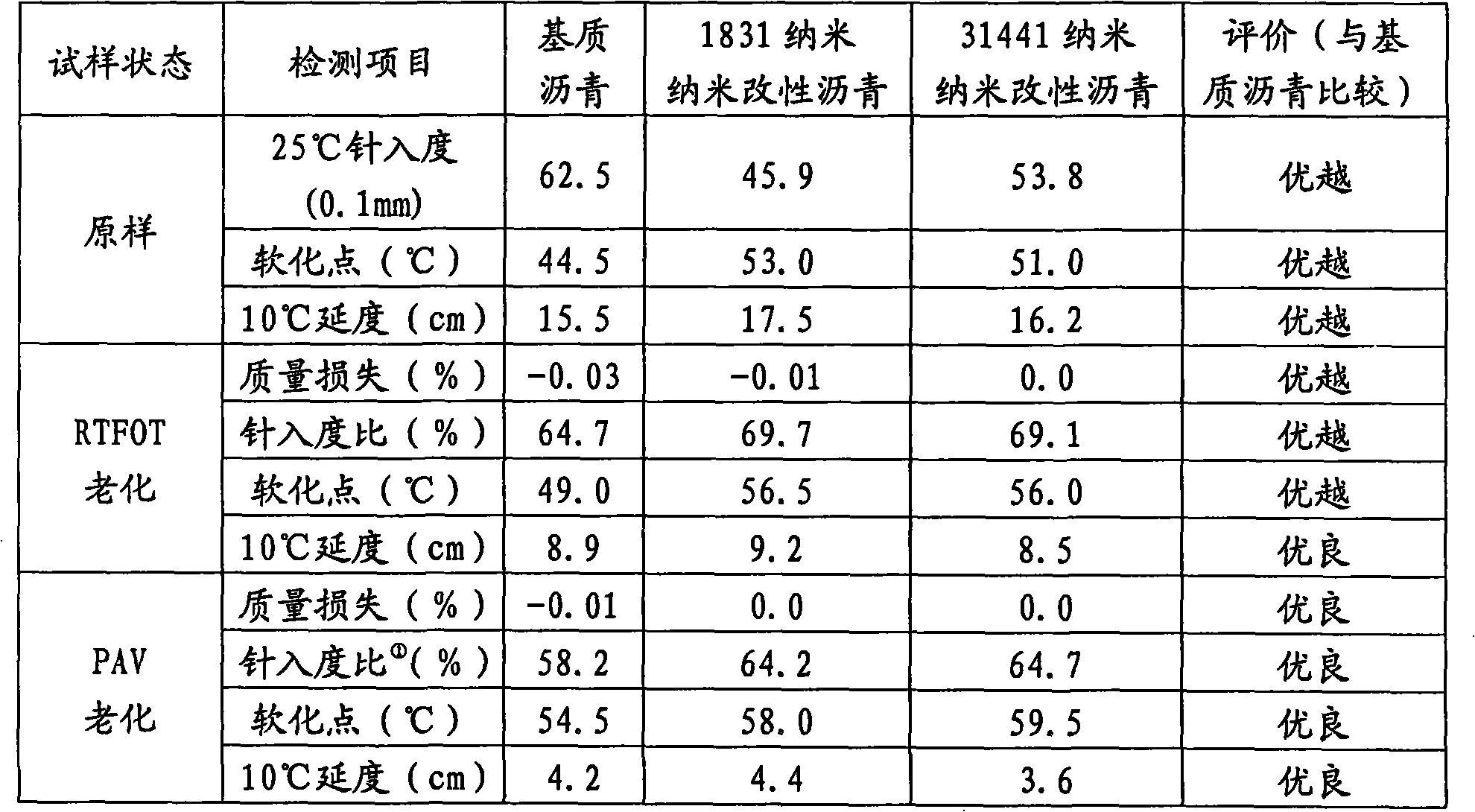

[0039] The improvement of the nano-modified asphalt in the above-mentioned embodiment in example 3 aspect high temperature stability

[0040] 1) Improved high temperature performance of asphalt

[0041] The high-temperature stability performance indicators of asphalt binder include: the softening point T obtained from conventional tests R&B , equivalent softening point T 800 ; G in the dynamic shear test of the index reflecting high temperature stability in the SHRP standard * / sinδ and the critical temperature T in the dynamic shear rheological test 1 (G * / sinδ=1.0KPa, before aging) and T 2 (G * / sinδ=2.2KPa, after rotating thin film aging RTFOT). The asphalt sample prepared in this example was tested by the laboratory testing center, and the test results of its high temperature performance are shown in Table 1.

[0042] Table 1 Test results of high temperature performance indicators of asphalt

[0043]

[0044] Note: T R&B is the softening point of asphal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com