Material for waste asphalt regeneration pavement and preparation method of material

A technology for waste asphalt and recycled pavement, applied in building insulation materials, solid waste management, sustainable waste treatment, etc., can solve the problems of insufficient grading treatment, low recovery rate, etc. The effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

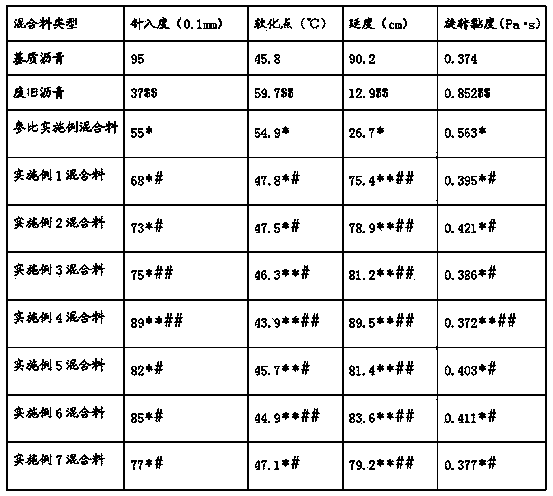

Examples

Embodiment 1

[0031] Embodiment 1 Waste and old asphalt regeneration pavement material of the present invention

[0032] The waste asphalt regeneration pavement material is composed of the following components: 1 part of light oil, 10 parts of waste rubber powder, 3 parts of plasticizing component, 100 parts of modified main agent, 5 parts of thickening component, 2 parts of stabilizer share. Wherein the light oil is divided into naphthenic oil, and the waste rubber powder is activated waste rubber powder with a fineness of 40 meshes. The plasticizing component is dibutyl phthalate, and the tackifying component is C9 petroleum resin, which is stable The agent is dicumyl peroxide.

[0033] The preparation method of the above-mentioned waste asphalt recycled pavement materials is as follows: first, heat the modified main agent to 165°C, place it under a high-speed shearing machine, start the high-speed shearing machine and control the shearing speed of the high-speed shearing machine to 5000...

Embodiment 2

[0034] Embodiment 2 Waste and old asphalt regeneration pavement material of the present invention

[0035] The waste asphalt regeneration pavement material is composed of the following components: 1 part of light oil, 10 parts of waste rubber powder, 3 parts of plasticizing component, 100 parts of modified main agent, 5 parts of thickening component, 2 parts of stabilizer share. Wherein light oil is divided into naphthenic oil, waste rubber powder is activated waste rubber powder, and fineness is 40 orders, and described plasticizing component is dibutyl phthalate, and viscosifying component is C9# petroleum resin, The stabilizer is dicumyl peroxide.

[0036] The preparation method of the above-mentioned waste asphalt regeneration pavement material is as follows: first, heat the modified main agent to 175°C, place it under a high-speed shearing machine, start the high-speed shearing machine and control the shearing speed of the high-speed shearing machine to 3000 rpm min, th...

Embodiment 3- Embodiment 7

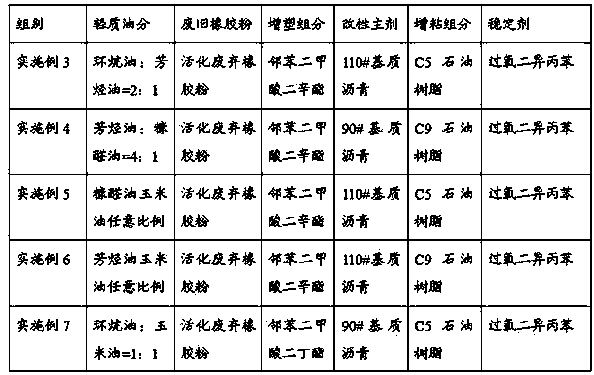

[0037] Example 3-Example 7 The waste and old asphalt regeneration pavement material and its preparation method of the present invention

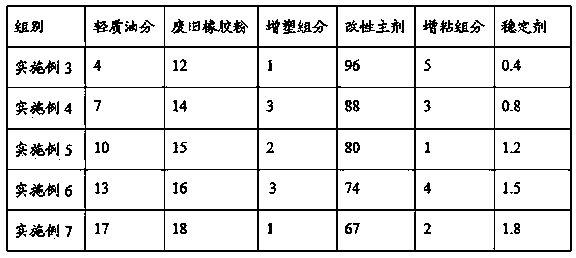

[0038] Components and contents in the waste and old asphalt regenerated pavement materials are shown in the following table:

[0039] Table 1 The number of components in the waste asphalt recycled pavement materials in Examples 3-7

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com