Layered steel fiber conductive bituminous concrete

A technology of asphalt concrete and conductive asphalt, which is applied to the coagulation pavement, roads, and pavement details of on-site paving, can solve the problems of restricting the development of steel fiber reinforced concrete pavement and high construction cost, reducing road maintenance costs and improving driving safety. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

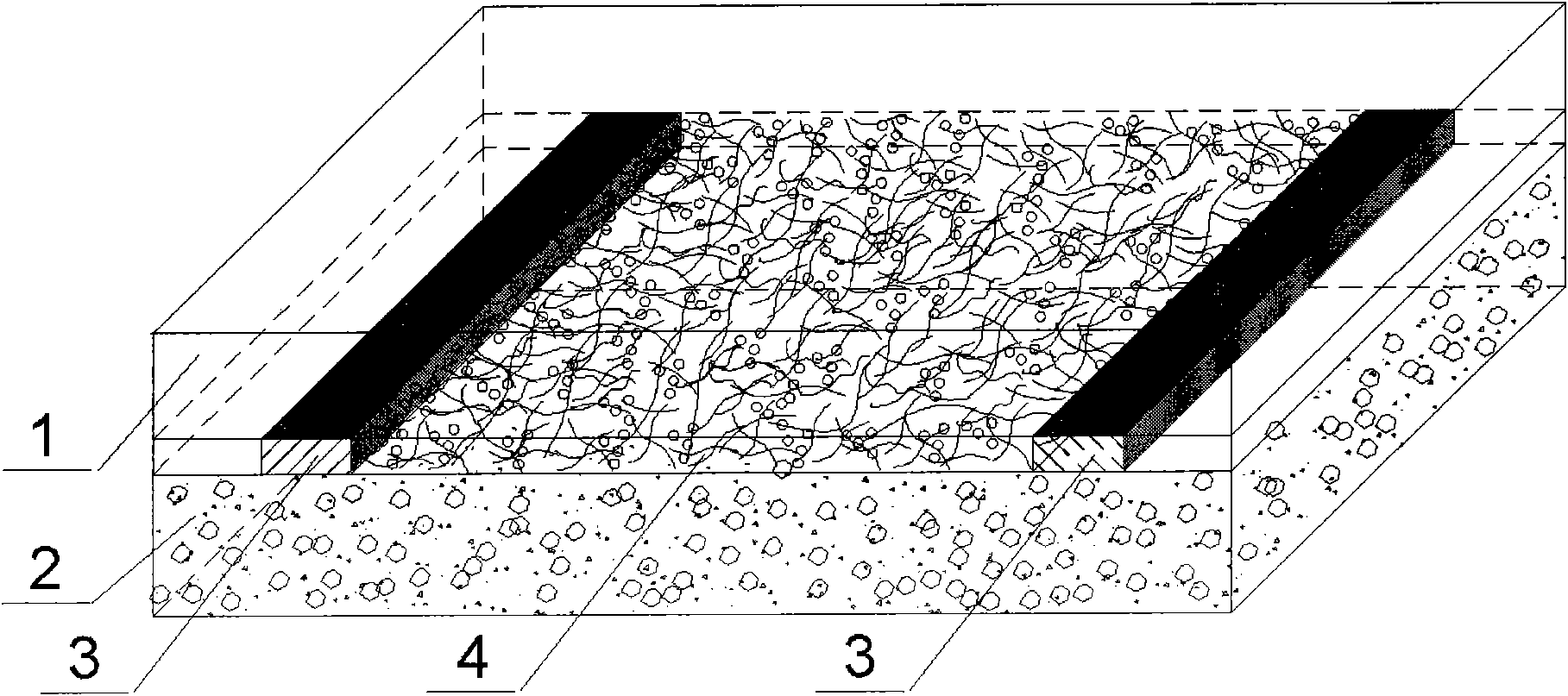

[0030] like figure 1 As shown, the layer-distributed steel fiber conductive asphalt concrete includes asphalt concrete surface layer 1, steel fiber layer 4, and lower bearing layer 2, asphalt concrete surface layer 1, steel fiber layer 4, and lower bearing layer 2 from top to bottom. Arrangement (bottom bearing layer 2, steel fiber layer 4, asphalt concrete surface layer 1 are arranged sequentially from bottom to top), and electrodes 3 are embedded in the steel fiber layer (stainless steel electrodes with a length of 300mm and a width of 10mm are arranged in parallel; electrodes and external power supply After connection, the electrothermal effect is used to remove ice and snow in cold seasons); the steel fiber layer is composed of steel fibers and conductive emulsified asphalt, the steel fibers are evenly laid on the surface of the lower bearing layer by spreading, and the conductive emulsified asphalt (sprayed) is sprayed on the steel fibers After the steel fibers, spray co...

Embodiment 2

[0036] like figure 1 As shown, the layer-distributed steel fiber conductive asphalt concrete includes asphalt concrete surface layer 1, steel fiber layer 4, and lower bearing layer 2, asphalt concrete surface layer 1, steel fiber layer 4, and lower bearing layer 2 from top to bottom. Arrangement, electrodes 3 are buried in the steel fiber layer (after the electrodes are connected to the external power supply, the electrothermal effect is used to deice and melt snow in cold seasons); the steel fiber layer is composed of steel fiber and conductive emulsified asphalt, and the steel fiber is laid evenly by spreading On the surface of the lower bearing layer, conductive emulsified asphalt is sprayed on the steel fibers (after the steel fibers are spread, conductive emulsified asphalt is sprayed to form an interpenetrating network structure), and the amount of steel fibers spread is 170g / m 2 , the spreading amount of conductive emulsified asphalt is 0.6L / m 2 .

[0037] The steel ...

Embodiment 3

[0047] like figure 1 As shown, the layer-distributed steel fiber conductive asphalt concrete includes asphalt concrete surface layer 1, steel fiber layer 4, and lower bearing layer 2, asphalt concrete surface layer 1, steel fiber layer 4, and lower bearing layer 2 from top to bottom. Arrangement, electrodes 3 are buried in the steel fiber layer (after the electrodes are connected to the external power supply, the electrothermal effect is used to deice and melt snow in cold seasons); the steel fiber layer is composed of steel fiber and conductive emulsified asphalt, and the steel fiber is laid evenly by spreading On the surface of the lower bearing layer, conductive emulsified asphalt is sprayed on the steel fibers (after the steel fibers are spread, the conductive emulsified asphalt is sprayed immediately to form an interpenetrating network structure), and the amount of steel fibers spread is 330g / m 2 , the spreading amount of conductive emulsified asphalt is 0.8L / m 2 .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com