Asphalt mastic macadam mixture and preparation method thereof

A technology of asphalt mastic and mixture, which is applied in the field of road engineering materials, can solve problems such as low road surface strength, impact on traffic conditions, and early damage to the road surface, so as to improve high temperature stability, aging resistance, and bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

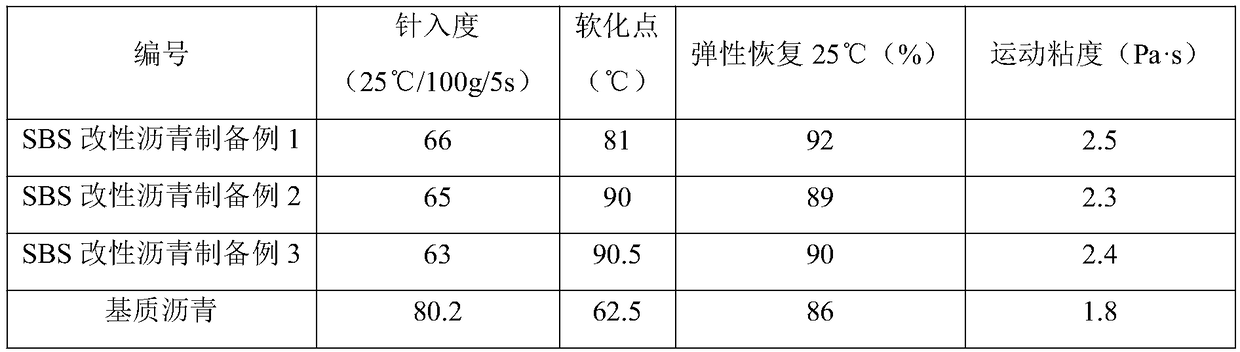

preparation example 1

[0035] Heat 100kg of base asphalt to 165°C, then add 5kg of SBS resin, shear at high speed for 2 hours, add 3kg of polybutene-terephthalate-polyether glycol block polymer, 3kg of nano-silicon dioxide, Sulfur powder 0.3kg, then heat up to 175°C to grind the resulting mixture, then add 1kg of rubber softening oil, control the temperature at 180°C and stir for 2 hours, lower the temperature to 170°C, add 0.18kg of stabilizer and stir for 1 hour , That is, SBS modified asphalt.

preparation example 2

[0037] Heat 100kg of base asphalt to 170°C, then add 8kg of SBS resin, shear at high speed for 2.5 hours, add 5kg of polybutene-terephthalate-polyether glycol block polymer, 4kg of nano-silica, Sulfur powder 0.4kg, then heat up to 178°C to grind the resulting mixture, then add soft rubber oil 3kgkg, control the temperature at 183°C and stir for 2.5 hours, lower the temperature to 173°C, add 0.26kg of stabilizer and stir for 1.5 hours , That is, SBS modified asphalt.

preparation example 3

[0039] Heat 100kg of base asphalt to 175°C, then add 10kg of SBS resin, shear at high speed for 3 hours, add 8kg of polybutene-terephthalate-polyether glycol block polymer, 5kg of nano-silica, Sulfur powder 0.5kg, then heat up to 180°C to grind the resulting mixture, then add 5kg of rubber softening oil, control the temperature at 185°C and stir for 3 hours, lower the temperature to 175°C, add 0.35kg of stabilizer and stir for another 2 hours , That is, SBS modified asphalt.

[0040] Preparation example 1 of modified wood fiber

[0041] Dissolve 4kg of maleic anhydride in 6kg of N,N-dimethylformamide solution, then add 0.4kg of hydroquinone, stir for 20 minutes, add 2kg of wood fiber, control the temperature at 75°C for 1 hour, vacuum-filtered to obtain product A, the resulting product A was soaked in acetone for 30 minutes, stirred for 3 hours, vacuum-filtered again to obtain product B, the resulting product B was placed in an oven, and kept at 80°C for 12 hours to dry, Tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com